Method for preparing granulated slow-digestion starch by restriction enzymolysis

A technology for digesting starch and restriction enzymes, which is applied in the field of preparation of granular slow-digesting starch, and can solve the problems that granular starch cannot be produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

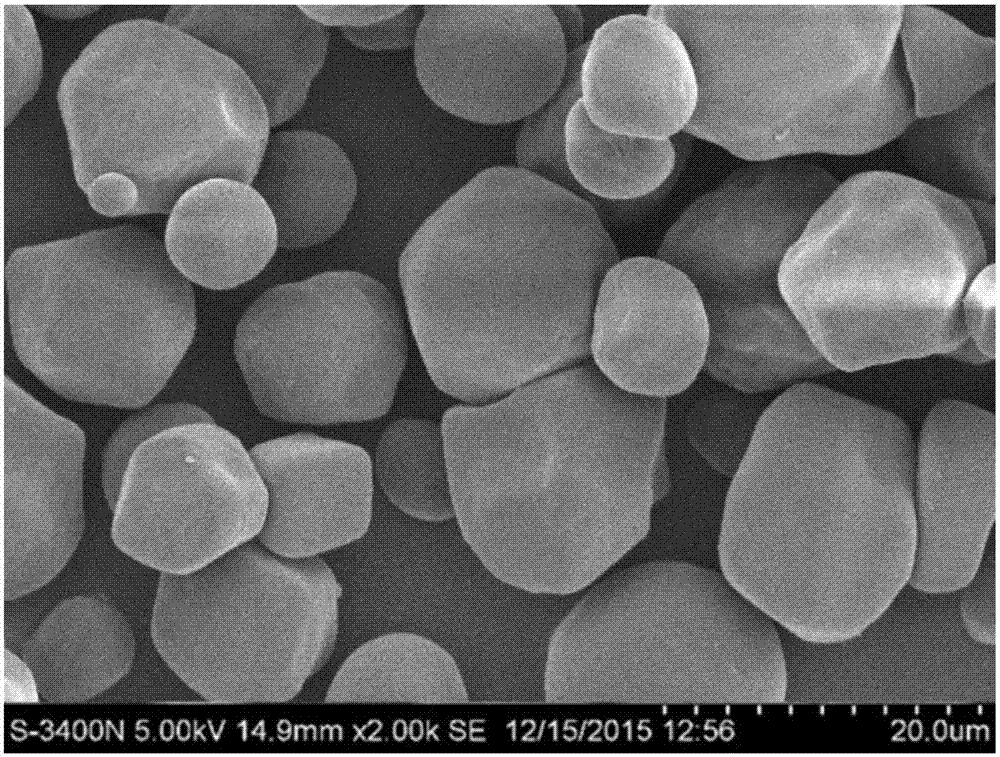

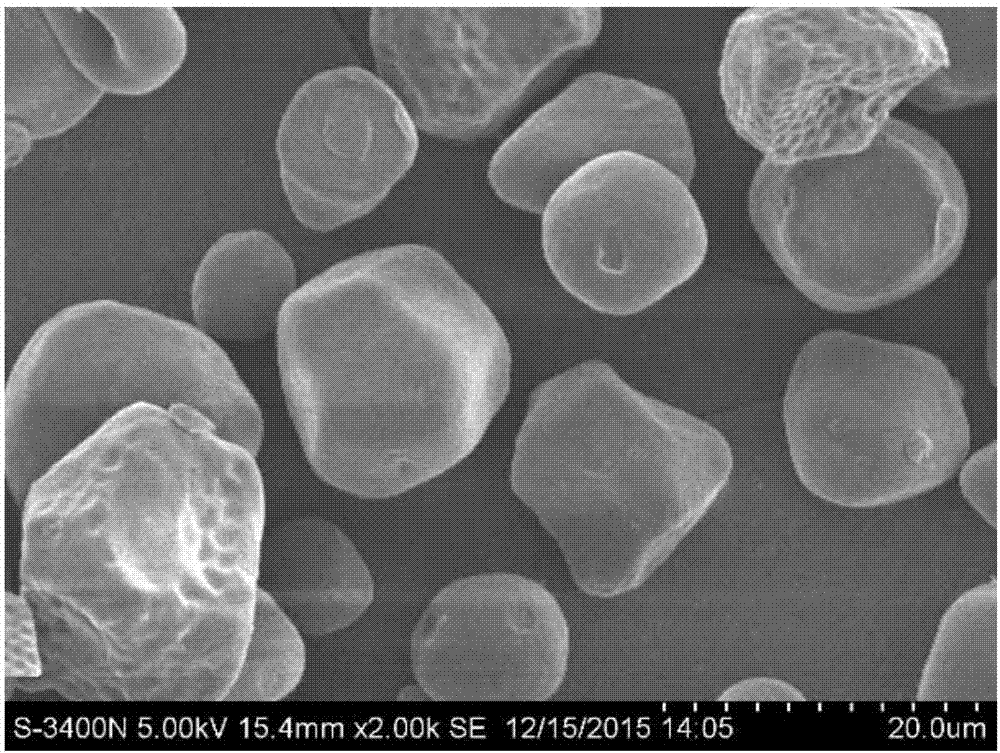

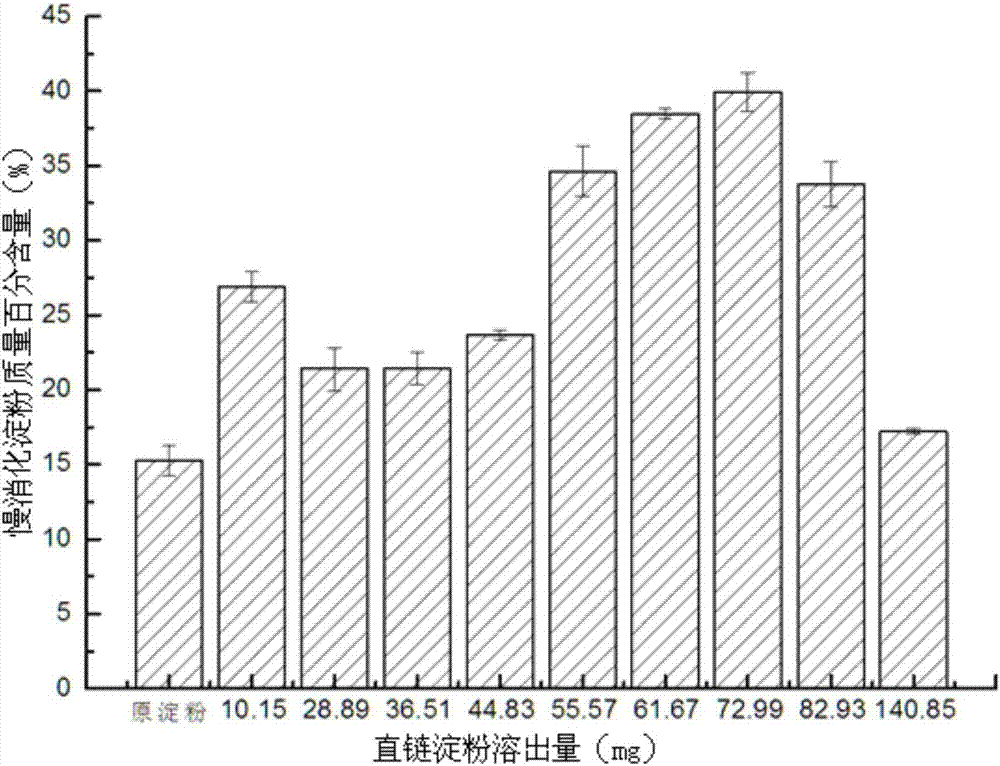

[0024] Embodiment 1: A method for preparing granular slow-digestible starch by restriction enzymolysis according to the present embodiment is carried out according to the following steps:

[0025] 1. Preparation of starch milk: Add a buffer solution with a pH value of 4 to 5 to the starch, mix well to obtain starch milk, and then place the starch milk in a constant temperature water bath at a temperature of 30 to 60°C to preheat for 5 minutes to 15 minutes;

[0026] The ratio of the mass of the starch to the volume of the buffer solution in step 1 is 5g-40g:100mL;

[0027] 2. Enzyme hydrolysis: add enzyme to the preheated starch milk in step 1, then seal it, shake it in a constant temperature water bath with a temperature of 30-55°C for 6h-14h, and then add NaOH with a mass fraction of 3%-5% The solution is stopped and centrifuged to obtain supernatant and precipitate;

[0028] The ratio of the amount of enzyme added in step 2 to the mass of starch in step 1 is 10U to 50U: 1g...

specific Embodiment approach 2

[0031] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the starch described in step 1 is cereal starch. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the cereal starch is one or any combination of wheat, corn and rice. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com