Residual iron discharging method for vanadium-titanium ore smelting furnace

A vanadium-titanium ore and blast furnace technology, which is applied in the field of vanadium-titanium ore metallurgy, can solve the problems of vanadium-titanium ore with residual iron, high labor intensity, and high griddle cost, so as to shorten the maintenance period, reduce labor intensity, and reduce griddle cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

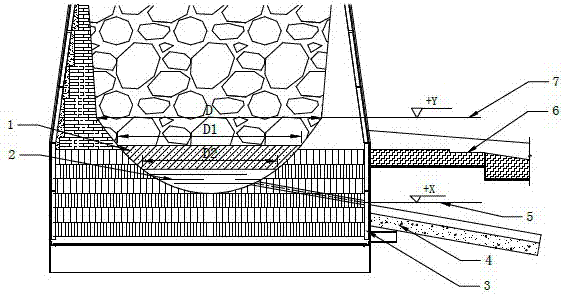

[0033] Please refer to figure 1 The method for discharging residual iron in the vanadium-titanium ore smelting blast furnace provided by the embodiment of the present invention comprises the following steps:

[0034] (1) Use the comparison analysis method to calibrate the position of the residual iron hole:

[0035] The erosion of the blast furnace bottom and hearth of ordinary ore smelting is "garlic head shape" or "elephant foot shape", while the erosion of blast furnace bottom and hearth of vanadium-titanium ore smelting is "conical erosion 1 + pot bottom erosion 2", The method of furnace skin temperature measurement cannot be used to determine the elevation of the residual iron mouth. After collation of previous griddle data and statistical data, it is found that the elevation X of the central line 5 of the residual iron mouth o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com