Dual-corrosion-resistant weather-resistant steel enamel heat transfer elements and preparation method thereof

A technology of heat transfer elements and weathering steel, which is applied in the direction of laminated elements, heat exchange equipment, lighting and heating equipment, etc., and can solve problems such as non-corrosion resistance and lack of enamel layer protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for preparing a double anti-corrosion weathering steel enamel heat transfer element, comprising the following steps:

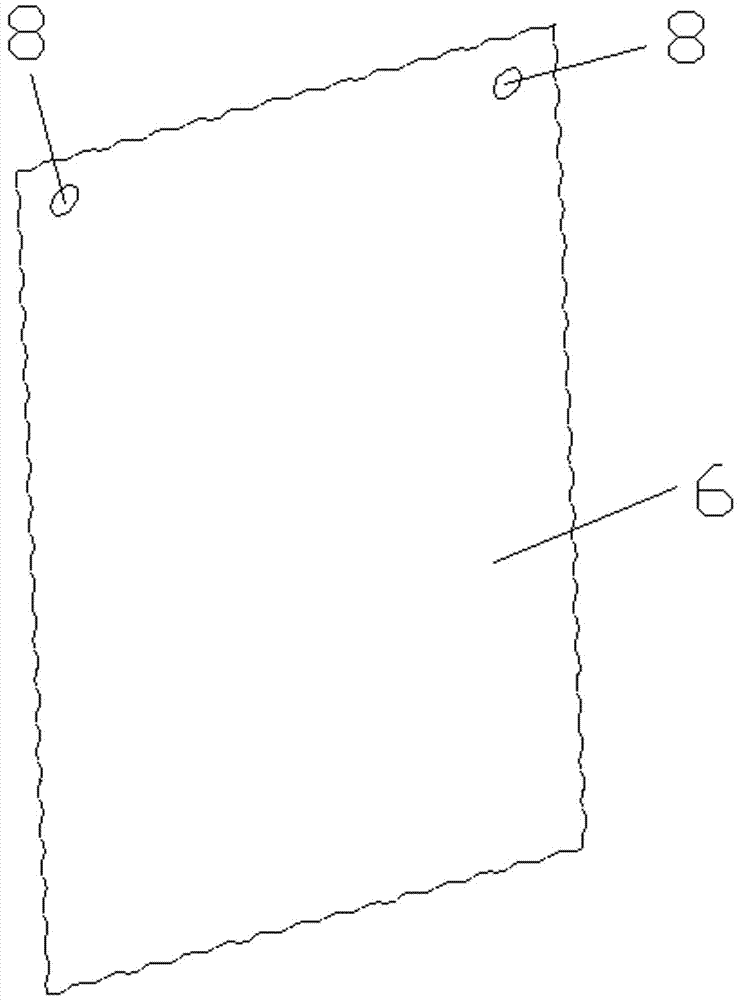

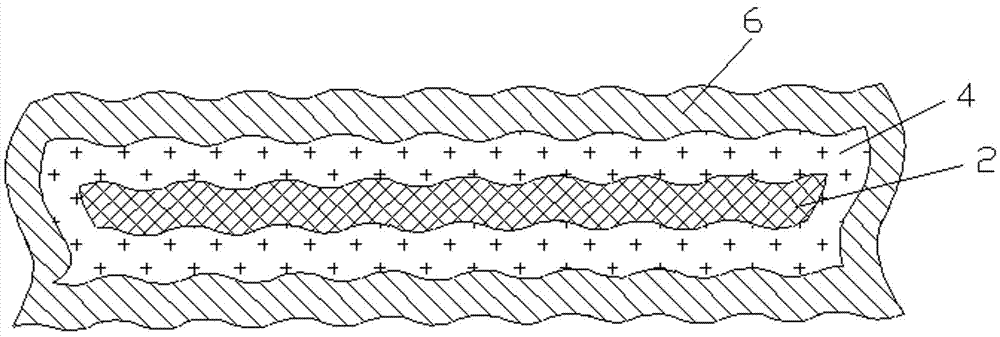

[0031] (1) The weather-resistant steel substrate 2 is rolled from weather-resistant steel;

[0032] (2) Two hanging holes 8 are opened on the weathering steel substrate 2, and the transitional enamel glaze is wet-coated on the surface of the weathering steel substrate 2 and the walls of the two hanging holes to form a transitional porcelain layer 4 , the transition enamel glaze includes protective enamel glaze, nickelous oxide, cobalt oxide and clay, and the protective enamel glaze includes the following components in mass percentage: 0% Al 2 o 3 , 3% B2 o 3 , 1% BaO, 0% CaO, 0% CoO, 0% CuO, 0% F2, 0% K 2 O, 1% Li 2 O, 10% Na 2 O, 0% NiO, 75% SiO 2 , 5% TiO 2 , 5% ZrO 2 Nickel oxide accounts for 0.1% of the quality of the protective enamel glaze, cobalt oxide accounts for 0.2% of the quality of the protective enamel glaze, and clay a...

Embodiment 2

[0036] A method for preparing a double anti-corrosion weathering steel enamel heat transfer element, comprising the following steps:

[0037] (1) The weather-resistant steel substrate 2 is rolled from weather-resistant steel;

[0038] (2) Two hanging holes 8 are opened on the weathering steel substrate 2, and the transitional enamel glaze is wet-coated on the surface of the weathering steel substrate 2 and the walls of the two hanging holes to form a transitional porcelain layer 4 , the transition enamel glaze includes protective enamel glaze, nickelous oxide, cobalt oxide and clay, and the protective enamel glaze includes the following components in mass percentage: 3% Al 2 o 3 , 10% B 2 o 3 , 5% BaO, 1% CaO, 2% CoO, 1% CuO, 2% F2, 2% K 2 O, 5% Li 2 O, 15% Na 2 O, 2% NiO, 50% SiO 2 , 1% TiO 2 , 1% ZrO 2 Nickel oxide accounts for 0.3% of the quality of the protective enamel glaze, cobalt oxide accounts for 0.8% of the quality of the protective enamel glaze, and cla...

Embodiment 3

[0042] A method for preparing a double anti-corrosion weathering steel enamel heat transfer element, comprising the following steps:

[0043] (1) The weather-resistant steel substrate 2 is rolled from weather-resistant steel;

[0044] (2) Two hanging holes 8 are opened on the weathering steel substrate 2, and the transitional enamel glaze is wet-coated on the surface of the weathering steel substrate 2 and the walls of the two hanging holes to form a transitional porcelain layer 4 , the transitional enamel glaze includes protective enamel glaze, nickelous oxide, cobalt oxide and clay, and the protective enamel glaze includes the following components in mass percentage: 1% Al 2 o 3 , 7% B 2 o 3 , 2% BaO, 3% CaO, 3% CoO, 3% CuO, 3% F2, 3% K 2 O, 2% Li 2 O, 8% Na 2 O, 3% NiO, 58% SiO 2 , 2% TiO 2 , 2% ZrO 2 Nickel oxide accounts for 0.5% of the quality of the protective enamel glaze, cobalt oxide accounts for 1.5% of the quality of the protective enamel glaze, and cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com