Method for measuring formaldehyde, acetaldehyde and acetone in tobacco water-based adhesive by derivatization-headspace gas chromatography

A technology of headspace gas chromatography and tobacco water-based glue, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high-performance liquid chromatography analysis applications, organic solvents are not environmentally friendly, and phenylhydrazone is easy to hydrolyze, etc., to achieve simplification Pre-treatment process, no consumption of organic solvent, effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

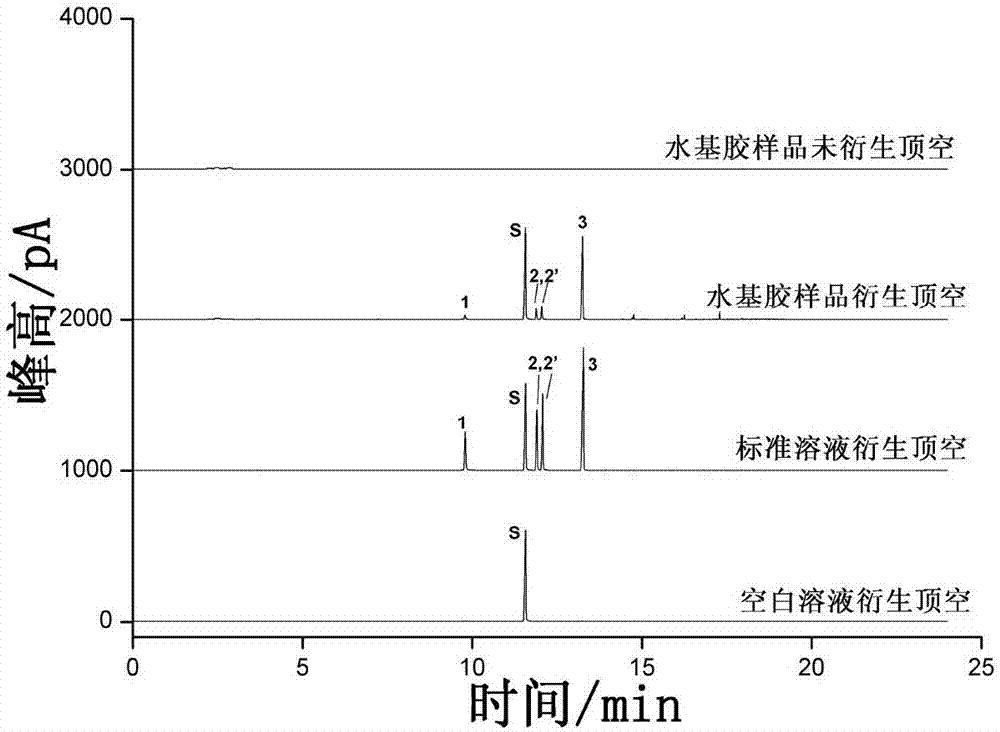

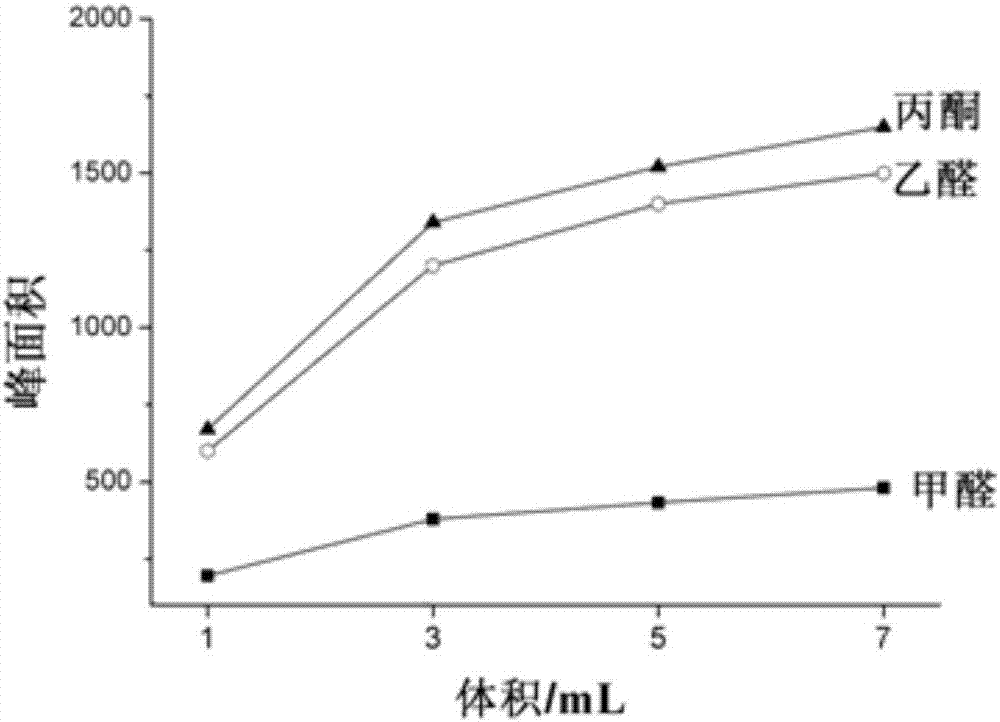

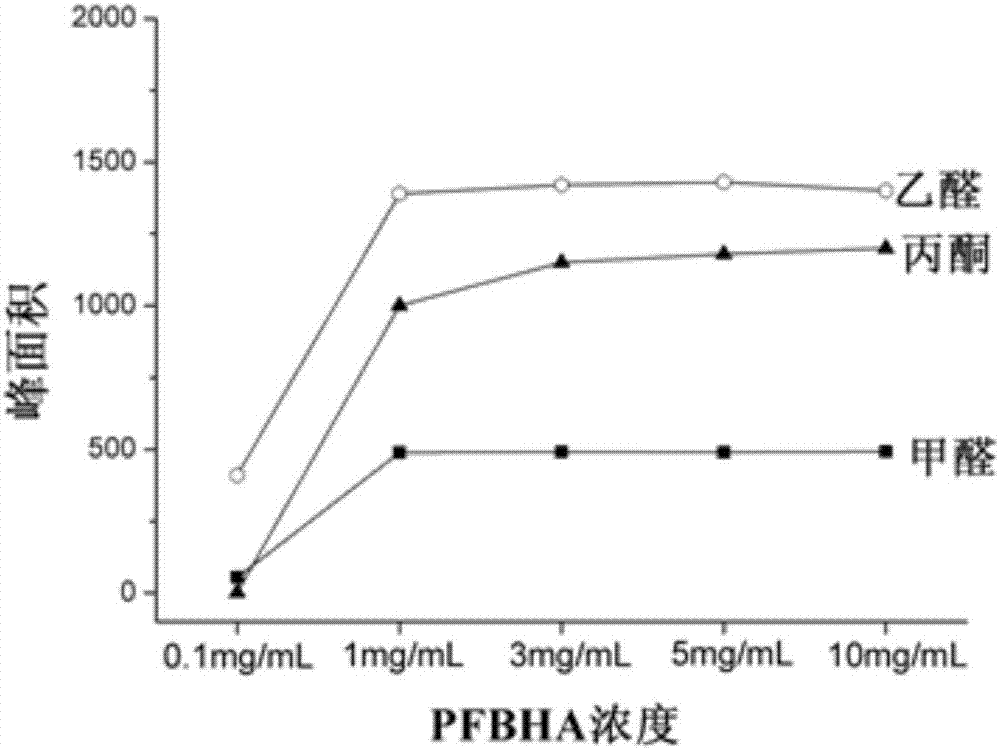

Examples

Embodiment 1

[0040] 1 Experimental part

[0041] 1.1 Materials, reagents and instruments

[0042] Water-based adhesive samples (provided by Zhejiang China Tobacco Industrial Co., Ltd.). Formaldehyde, acetaldehyde, acetone single standard solution (1.0mg / mL, Bailingwei Technology Co., Ltd.); pentafluorobenzyl hydroxylamine standard (Tokyo Chemical Industry Co., Ltd.). Model 7890 gas chromatograph (with HP-7697A headspace sampler), HP-5 chromatographic column (30m×0.25mm×0.25μm) (Agilent, USA); AG104 electronic balance (sensitivity 0.0001g, Swiss Metter-Toledo company); Milli-Q Advantage A10 ultrapure water system (Millipore, USA); vortex mixer (Qilin Bell Instrument Co., Ltd. Haimen); Sigma 4-16k high-speed centrifuge (Sigma, Germany).

[0043] 1.2 Prepare mixed standard stock solution, mixed standard working solution and derivative reagent solution. : Accurately weigh 1.0mL formaldehyde standard solution, 5.0mL acetaldehyde standard solution, and 5.0mL acetone standard solution, and use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com