Power train of new energy electric vehicle

A technology for electric vehicles and powertrains, applied in the direction of electric power units, power units, vehicle components, etc., can solve the problems of increasing the production cost of the whole vehicle, complex gearbox structure, high manufacturing cost, etc. The effect of reducing the workload of assembly and maintenance and improving the accuracy and speed of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

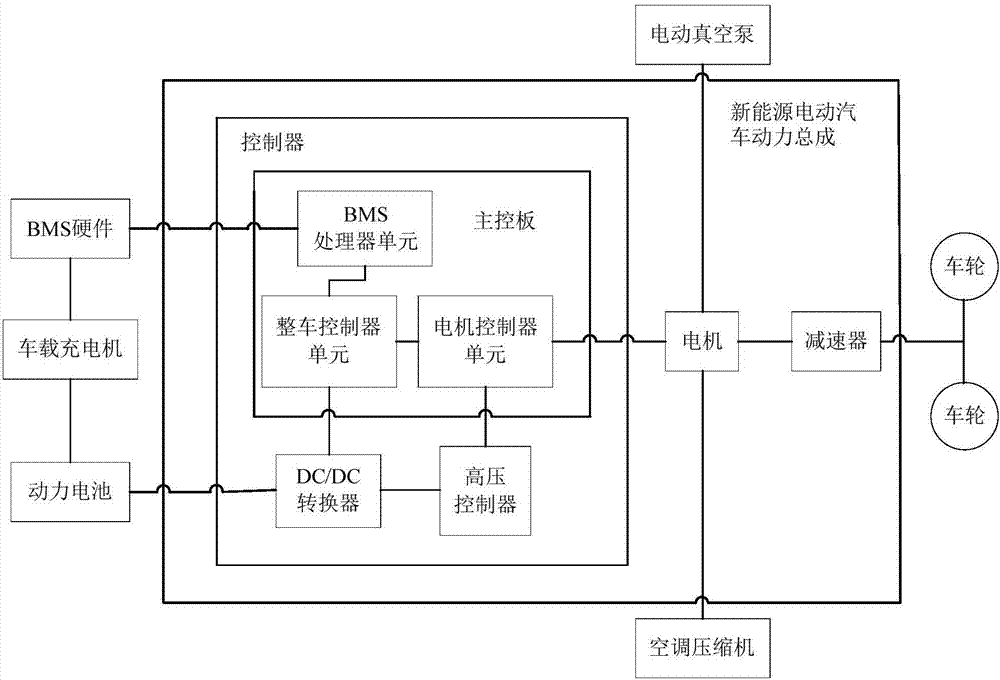

[0018] Such as figure 1 As shown, the powertrain is the core component of the vehicle chassis. If a new energy vehicle wants to drive, it cannot do without the role of the powertrain. The present invention includes a controller, a motor and a reducer connected to the output end of the motor. The controller includes a main control board, a DC / DC converter and a high-voltage controller respectively connected to the main control board, wherein the output end of the main control board It is connected with the input end of the motor, and the DC / DC converter is connected with the high voltage controller.

[0019] Through analysis and verification, the technical solution of the present invention has been simplified and integrated. Specifically, since the motor can be started with load, the present invention does not require the clutch of a tradition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com