A method for removing organic matter in inorganic salts

A technology of organic matter and inorganic salt, applied in the direction of calcium/strontium/barium chloride, alkali metal halide purification, calcium/strontium/barium halide, etc., can solve the problem of excessive organic matter residue, liquid salt penetration, low heat transfer efficiency, etc. problems, to achieve the effect of shallow liquid level, prevent caking, and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

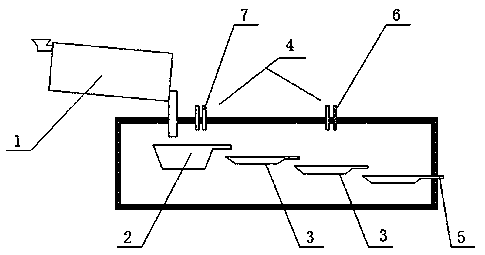

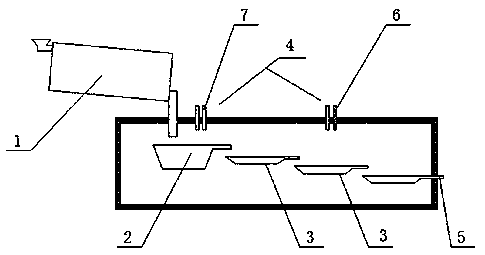

Image

Examples

Embodiment 1

[0040] The inorganic salt containing organic matter used in this example is taken from the salt evaporated and crystallized by a pesticide company in Anhui. It contains a large amount of organic matter residue, the content is 450mg / kg, especially contains a part of organic chloride (dioxin), Among them, the organic chloride content is 50mg / kg, and the waste salt is a typical hazardous waste salt.

[0041] The method for removing organic matter in inorganic salts comprises the following steps:

[0042] 1) The above waste salt was heated to 600°C by hot air in the rotary kiln 1 for cracking and oxidation, and the residence time at 600°C was 85 minutes to obtain gray solid salt. During this process, no salt cohesion was found. The content of organic matter in the solid salt after step cracking is 12.5mg / kg, and the content of dioxin is 4.5μg / kg. , so the salt treated in this step is still hazardous waste salt.

[0043]2) Put the cracked high-temperature solid salt into the molt...

Embodiment 2

[0045] The inorganic salt containing organic matter used in this example is taken from the salt evaporated and crystallized by a pesticide company in Shandong. It contains a large amount of organic matter residues, and the organic matter content is 680mg / kg, especially containing a part of organic chlorides (dioxins). , wherein the organic chloride content is 120mg / kg, waste salt is a typical hazardous waste salt.

[0046] The method for removing organic matter in inorganic salts comprises the following steps:

[0047] 1) Heat the above waste salt in the rotary kiln to 650°C with hot air for cracking and oxidation. The residence time at 650°C is 90 minutes to obtain gray solid salt. No salt caking was found during the operation. This step The content of organic matter in the cracked solid salt is 11.4 mg / kg, and the content of dioxin is 2.5 μg / kg. Although the content of organic matter in the salt has reached the standard for chlor-alkali salt, because it contains a small amou...

Embodiment 3

[0050] The inorganic salt containing organic matter in this example is taken from the salt obtained from the evaporation and crystallization of the pesticide chlorpyrifos wastewater, and contains a large amount of organic matter residue, wherein the organic matter content is 545mg / kg, especially containing a part of organic chloride (dioxin), Among them, the organic chloride content is 248mg / kg, and the waste salt is a typical hazardous waste salt.

[0051] The method for removing organic matter in inorganic salts comprises the following steps:

[0052] 1) Heat the above waste salt to 650°C with hot air in a stirred cracking furnace for cracking and oxidation, and the residence time at 650°C is 120 minutes to obtain gray solid salt. No salt sticking was found during the operation. The content of organic matter in the solid salt cracked in this step is 5.4 mg / kg, and the content of dioxin is 2.6 μg / kg. Although the content of organic matter in the salt has reached the standard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com