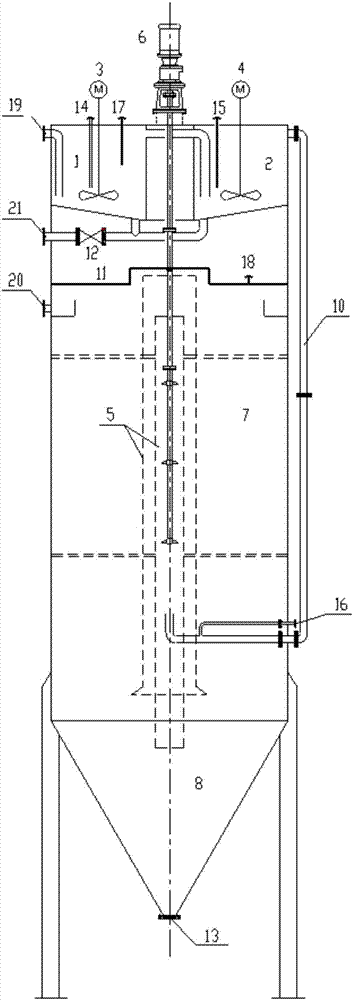

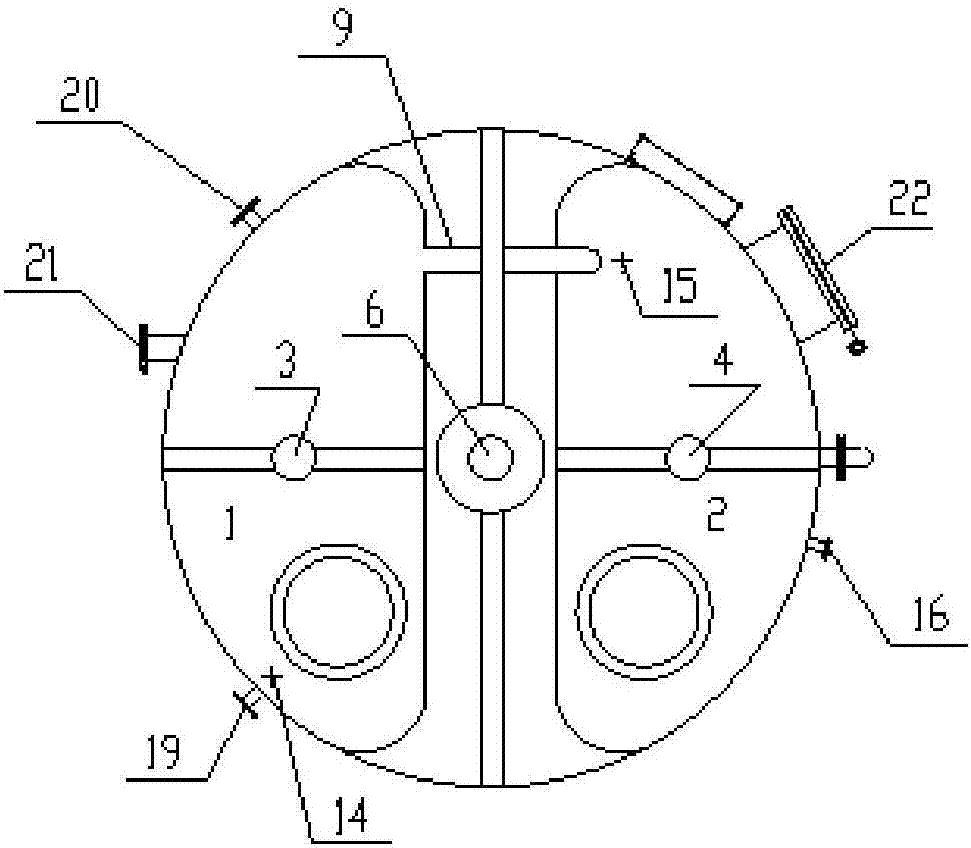

Integrated wastewater softening and clarifying device and method

A clarification device and integrated technology, applied in water softening, gaseous effluent wastewater treatment, etc., can solve the problems of high investment cost, long system treatment process, and large floor area, so as to reduce floor space and investment Low cost, the effect of reducing investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] After pre-sedimentation of desulfurization wastewater from a thermal power plant, the content of suspended solids is 2500mg / L, Ca 2+ The content is 1732mg / L, Mg 2+ The content is 16800mg / L, and the pre-settled desulfurization wastewater is transported to the primary reaction zone 1 through the wastewater lifting pump, and the dosage of NaOH is adjusted according to the flow rate of the desulfurization wastewater and the pH value of the mixed solution in the primary reaction zone 1, and then Stir the mixed solution in the primary reaction zone 1 by the primary agitator 3, the stirring time is 20min, then enter the secondary reaction zone 2, and add Na to the secondary reaction zone 2 2 CO 3 , so that the mixed solution in the secondary reaction zone 2 and Na 2 CO3 Stir the reaction for 20 minutes, the mixed solution overflowed from the secondary reaction zone 2 enters the bottom of the inner guide tube, and the reaction agitator 6 is lifted by flocculation to make the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com