Silane concrete staining material and preparation method and application thereof

A technology of concrete and staining agent, which is applied in the field of silane concrete staining agent and its preparation. It can solve the problems of uneven color on the ground, the sealing of color paste in it, and the loss of color effect, etc., and achieve stable hue, low surface strength, and non-fading color. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

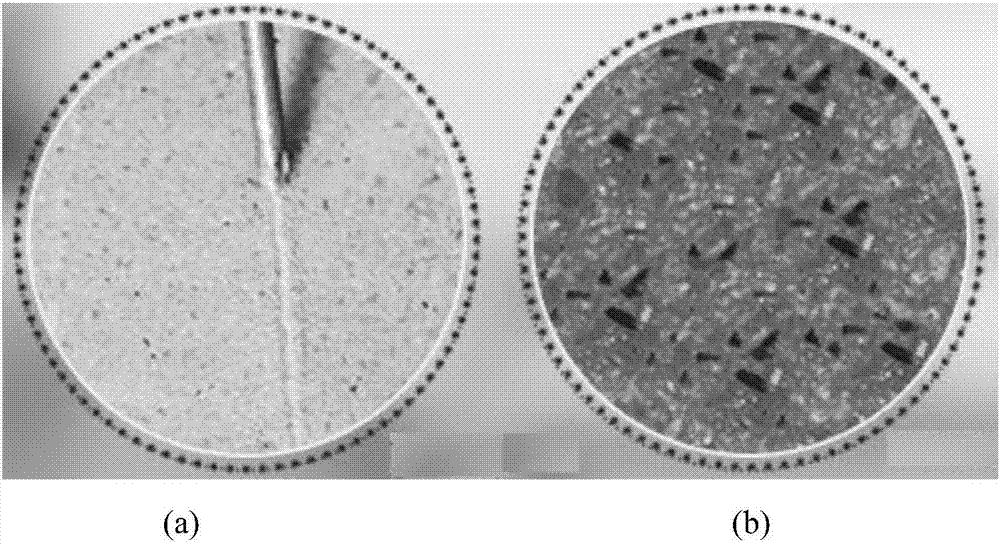

Image

Examples

Embodiment 1

[0038] Formula: 1 kg of γ-glycidyl etheroxypropyl trimethoxysilane, 1 kg of oily nano-color paste with a particle size of 50-200 nm, and 96 kg of ethanol.

[0039] Preparation method: dissolve the color paste in the solvent, stir evenly, then add alkoxysilane, mix evenly, and then the silane concrete stain of the present invention can be prepared.

[0040] Application: 1) Clean up the dust and debris on the concrete floor;

[0041] 2) Pretreatment of the concrete floor: first grind the concrete floor with a 50-mesh emery disc, then grind it with a 300-mesh emery disc, and finally grind it with a 500-mesh emery disc;

[0042] 3) Spray the above-mentioned silane concrete stain to make it fully penetrate into the concrete and combine with the concrete;

[0043] 4) After the above dyeing agent is completely dry, grind the ground;

[0044] 5) There should be no stagnant water within 24 to 72 hours of completion, and the curing period is 1 to 10 days;

[0045] 6) Finally, polish ...

Embodiment 2

[0047] Formula: 50 kg of γ-aminopropyltriethoxysilane, 10 kg of oily nano-color paste with a particle size of 50-200 nm, and 40 kg of isopropanol.

[0048] The preparation method and application method of the silane-mixed soil dyeing agent are the same as in Example 1.

Embodiment 3

[0050] Formula: 30 kg of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane, 5 kg of oily nano-color paste with a particle size of 50-200 nm, and 70 kg of ethylene glycol diacetate.

[0051] The preparation method and application method of the silane-mixed soil dyeing agent are the same as in Example 1.

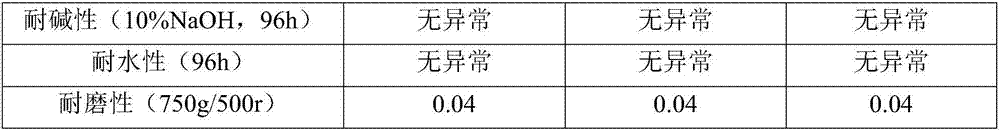

[0052] Product performance parameters are shown in Table 1.

[0053] Table 1 embodiment 1-3 silane concrete stain performance parameters

[0054] Test items Example 1 Example 2 Example 3 Dustproof effect clean clean clean Impermeability excellent excellent excellent Anti-aging over 60 years over 60 years over 60 years Anti-skid Excellent anti-skid performance Excellent anti-skid performance Excellent anti-skid performance clean No oil leakage, easy to clean No oil leakage, easy to clean No oil leakage, easy to clean Vulnerability Super strength and wear resistance Super strength and wear resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com