Method and device for permanently repairing defects of absent material of a photolithographic mask

A photolithography mask, permanent technology, applied in metal material coating process, originals for photomechanical processing, optics, etc., to increase long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

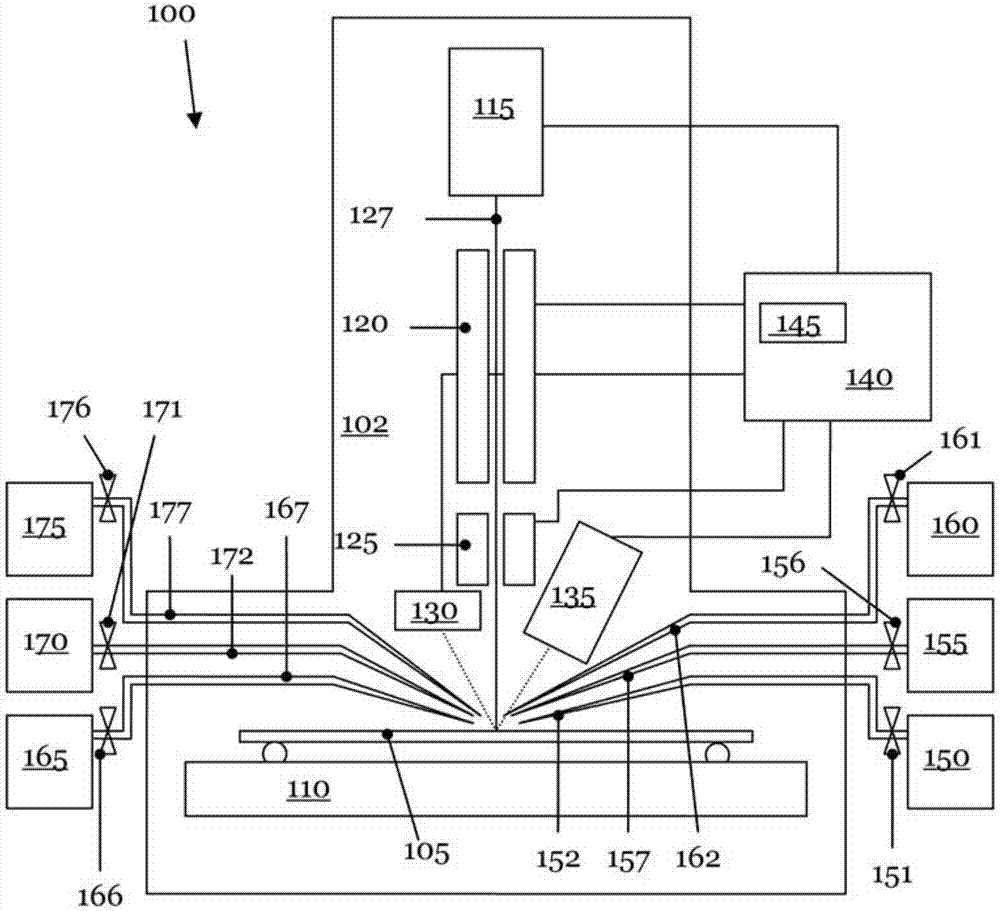

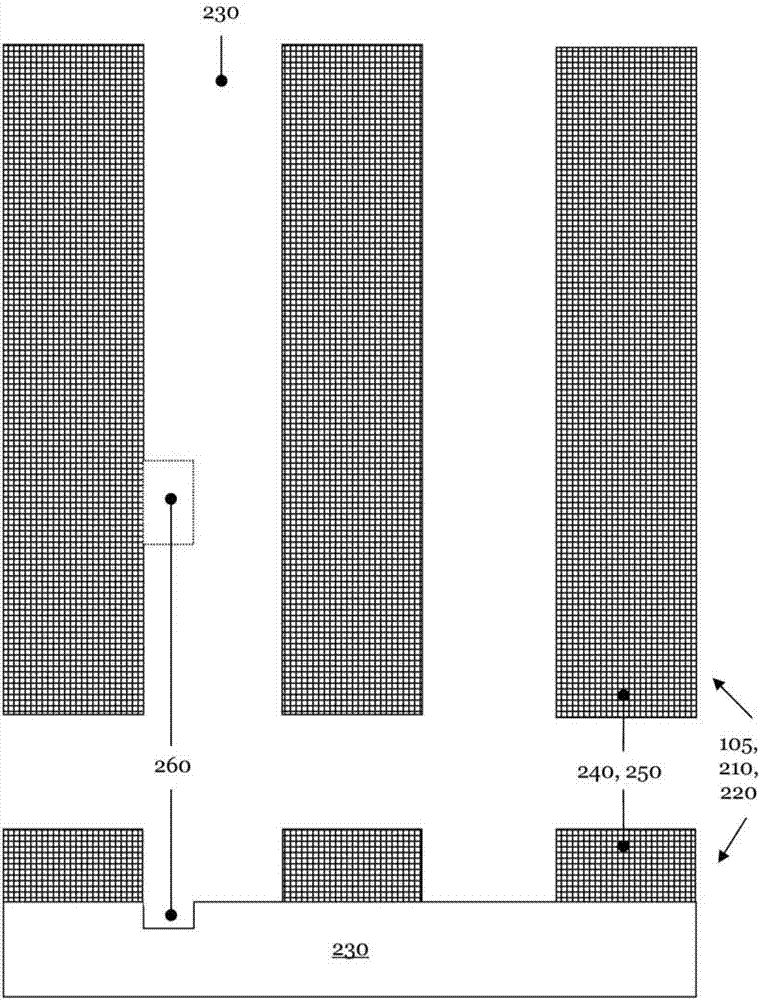

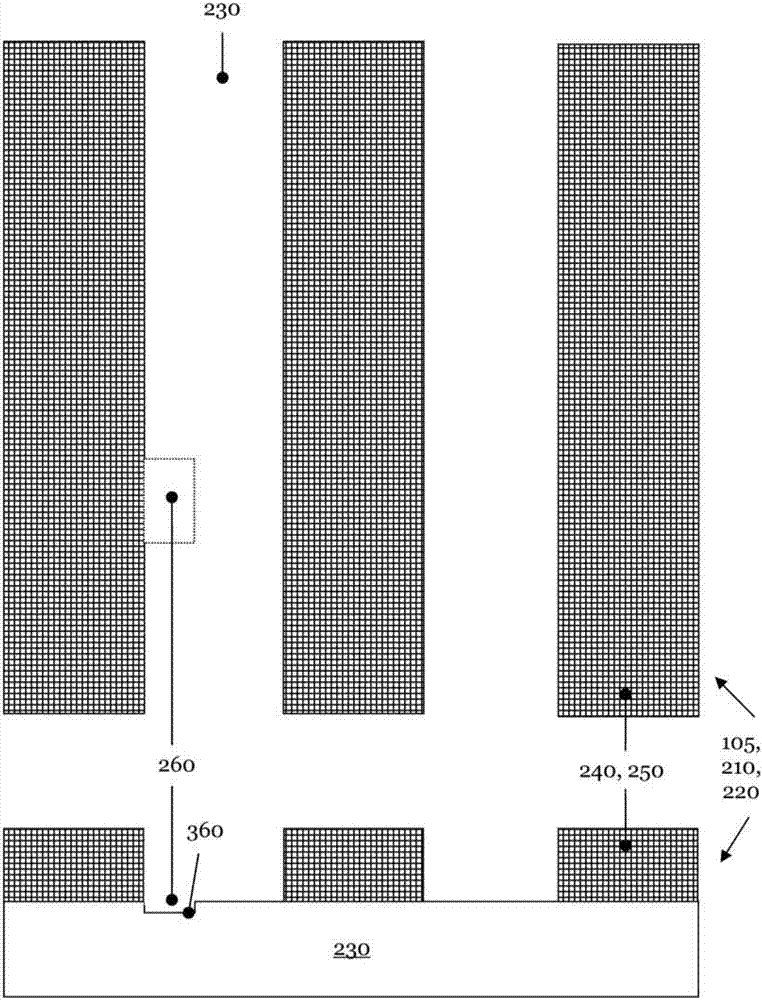

[0059] In the following, based on the example of a modified scanning electron microscope, a presently preferred embodiment of the device according to the invention for permanently repairing defects of material defects of photolithographic masks is explained in more detail. However, the device according to the invention is not limited to the examples described below. As the person skilled in the art will recognize without difficulty, instead of the scanning electron microscope in question, any scanning particle microscope using, for example, a focused ion beam and / or a focused photon beam as energy source may be employed. Furthermore, methods according to the present invention are not limited to the use of masks discussed through the following examples. Rather, the method can be used to repair any desired photolithographic mask. Furthermore, the application of the method according to the invention is not limited to application to photomasks. Conversely, the method can be used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com