Cyhalofop-butyl emulsion in water and preparation method thereof

A technology of cyhalofop-butyl and water emulsion, which is applied in the field of herbicide preparation, can solve the problems of large amount of emulsifier, large amount of emulsifier, many components, etc., and achieves the effects of improving deposition, reasonable components and simplifying processing flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

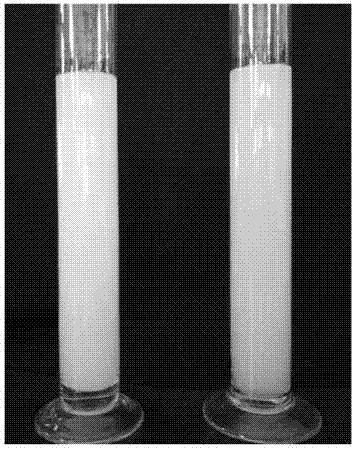

[0024] A preparation method of cyhalofop-ethyl aqueous emulsion, comprising the steps of:

[0025] (1) Dissolve 6% to 12% of cyhalofop-ethyl technical material in 8% to 15% solvent, and stir until transparent by magnetic force;

[0026] (2) Add 6% to 15% emulsifier and continue to stir to form a uniform oil phase;

[0027] (3) Add 2% to 6% antifreeze to deionized water to form a water phase;

[0028] (4) Under the action of magnetic stirring, add the water phase to the oil phase drop by drop, and stir at a speed of 500-1500r / min for 10-30min to obtain the cyhalofop-in-water emulsion.

Embodiment 1

[0030] (1) Add 4g of cyhalofop-ethyl technical material into a beaker, add 4g of solvent to it, add 4g of emulsifier after fully dissolving, and fully stir to form a homogeneous oil phase;

[0031] (2) Under magnetic stirring, 25 g of water in which 3 g of glycerin was dissolved was added dropwise to the oil phase;

[0032] (3) After the dropwise addition of water was completed, magnetic stirring was maintained at 1200r / min for 20min to obtain 40g of cyhalofop-ester aqueous emulsion.

Embodiment 2

[0034] (1) Add 4g of cyhalofop-ethyl technical material into a beaker, add 3.2g of solvent to it, add 4g of emulsifier after fully dissolving, and fully stir to form a homogeneous oil phase;

[0035] (2) In the case of magnetic stirring, 25.8 g of water in which 3 g of glycerol was dissolved was added dropwise to the oil phase;

[0036] (3) After the dropwise addition of water was completed, magnetic stirring was maintained at 1200r / min for 20min to obtain 40g of cyhalofop-ester aqueous emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com