Patents

Literature

37results about How to "The principle of preparation is clear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

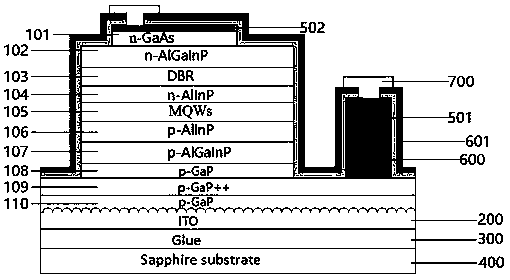

A flip-chip AlGaInP red light Micro-LED and a preparation method thereof

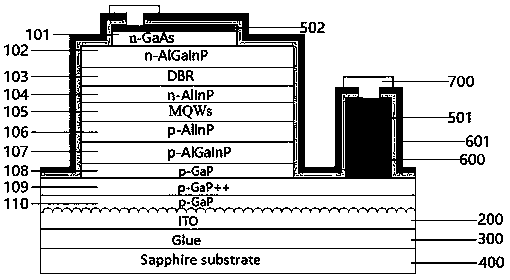

The invention belongs to the technical field of LED production and manufacture, and relates to a flip-chip structure AlGaInP red light Micro-LED and a preparation method thereof. The flip-chip structure AlGaInP red light Micro-LED includes an n-GaAs ohmic contact layer 101, an n-AlGaInP expansion layer 102, a DBR layer 103, an n-AlInP confinement layer 104, a light emitting layer 105, a p- AlInP confinement layer 106, a p- AlGaInP extended layer 107, a p-GaP current spread layer 108, a p-GaP ohmic contact lay 109, a p-GaP coarse bonding lay 110, an ITO layer 200, a cured layer 300, a substrate400, an electrode layer 501, a first metal layer 502, a protective layer 600, an ODR layer 601 and a second metal layer 700 ; the structure is novel, the working principle is clear, and the light emitting efficiency is improved; As that bonding layer between indium tin oxide (ITO) and the ultraviolet cure optical adhesive is used as a bonding layer connecting the sapphire, the bonding yield can be improved, and the technical route of the invention is reliable, the technical foundation is mature, the raw materials are easy to obtain, and the invention is favorable for batch production.

Owner:肖和平

Method for preparing biomedical magnesium alloy wire

ActiveCN106917022AThe principle of preparation is clearMeet the requirements of strength and plasticitySingle phaseCorrosion

The invention provides a method for preparing a biomedical magnesium alloy wire and belongs to the technical field of metal materials. The method comprises the following steps: melting magnesium and zinc into liquid metal, stirring and refining the liquid metal to obtain refined liquid metal, and casting the refined liquid metal into an alloy ingot; then, carrying out homogenizing heat treatment on the alloy ingot or directly carrying out equal-channel pressing without heat treatment; and finally, machining the magnesium-zinc alloy subjected to the equal-channel pressing into the biomedical magnesium alloy wire through multi-channel drawing. According to the method, a single-phase oversaturated solid solution tissue is obtained after the wire drawing is finished, so that the strength and the ductility of the biomedical magnesium alloy wire are both higher than those of a wire which is directly drawn without equal-channel pressing. Accordingly, not only are the strength and ductility requirements met, but also the material corrosion resistance is greatly improved.

Owner:YANGZHOU UNIV

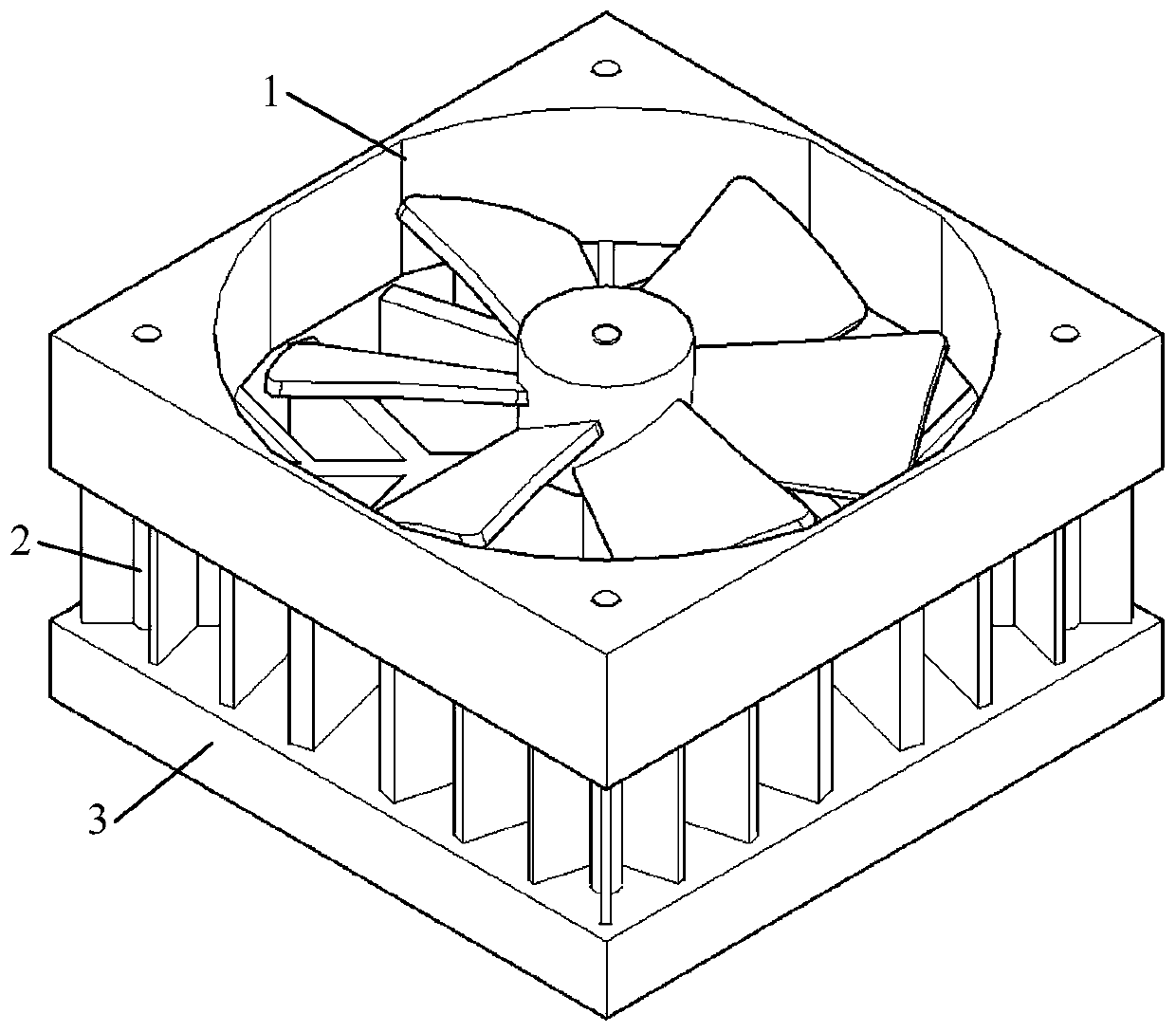

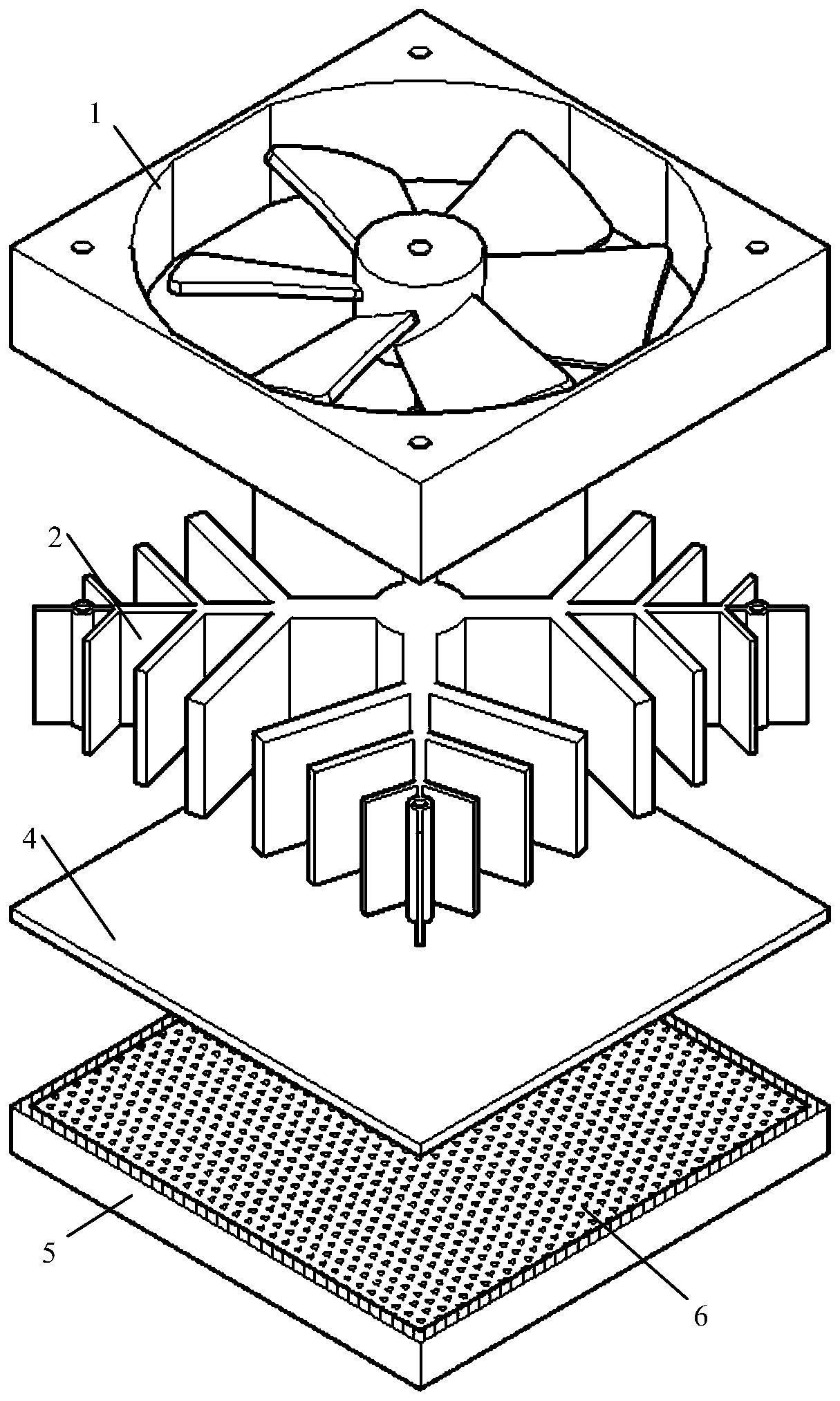

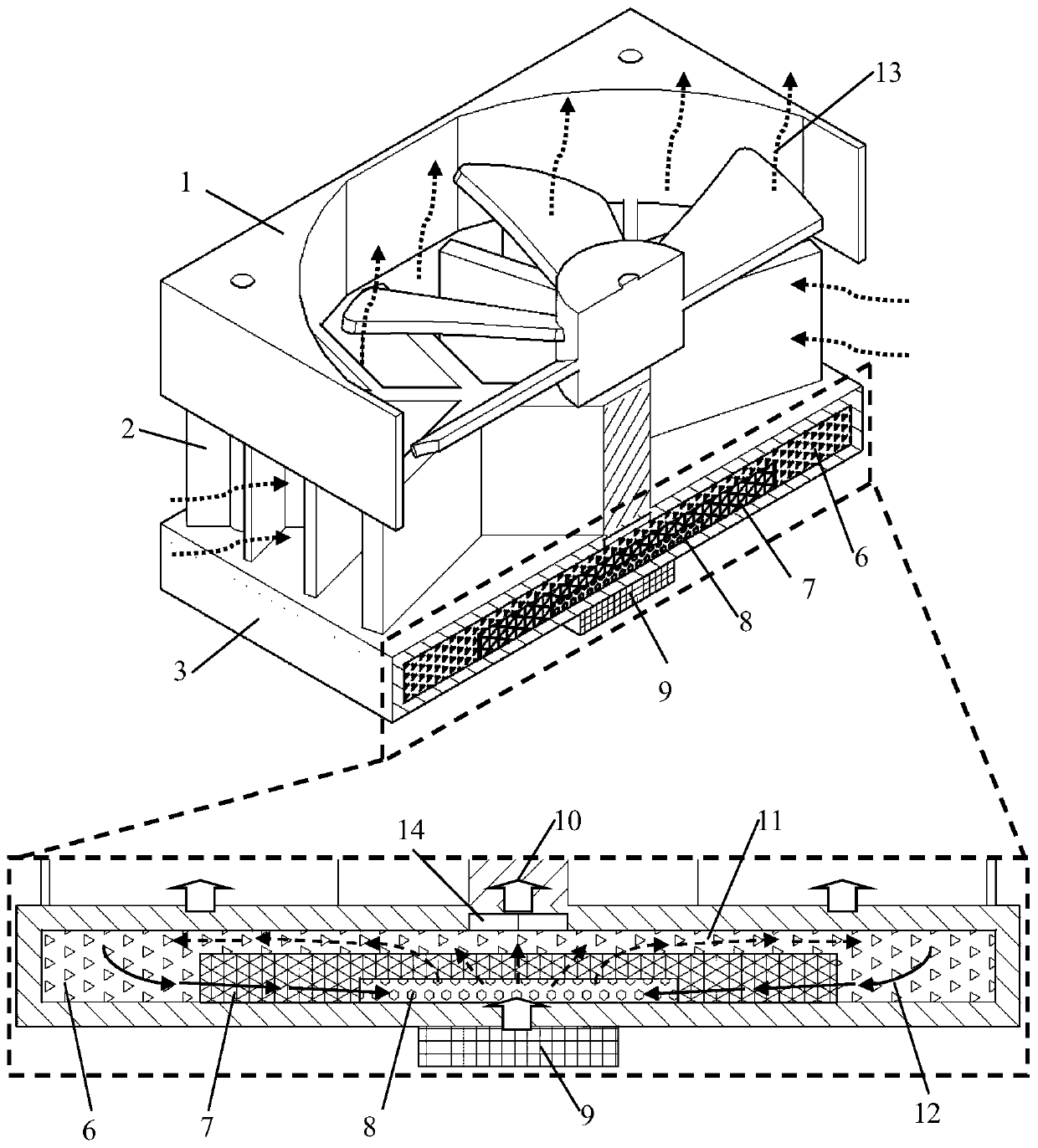

Gradient-sized pore sintered core vapor chamber heat exchanger for electronic chip heat dissipation and preparation method of vapor chamber heat exchanger

PendingCN110010569AFacilitated DiffusionPromote refluxSemiconductor/solid-state device detailsSolid-state devicesSuction forceElectronic chip

The invention discloses a gradient-sized pore sintered core vapor chamber heat exchanger for electronic chip heat dissipation and a preparation method of the vapor chamber heat exchanger, belongs to the technical field of electronic chip heat dissipation. The vapor chamber heat exchanger is composed of a sintered core vapor chamber, heat dissipation fins, and a heat dissipation fan. A vapor chamber housing is filled with a gradient-sized pore sintered core. A vein-shaped channel is milled on the chamber top of the vapor chamber. Fins are welded to the outer top of the vapor chamber. The vaporchamber and the heat dissipation fan are fixedly installed. The bottom center of the vapor chamber is in contact with the chip in order to take away the heat released by the chip. The gradient-sized pore sintered core interacts with the top vein-shaped channel, thereby contributing to the rapid diffusion of steam to a cold wall, the return of a condensation liquid to the heated area at the bottomcenter of the vapor chamber with a small resistance under the effect of high capillary suction force, and the enhancement of the boiling and condensation heat capacity, increasing the boiling and condensation heat exchange area, greatly improving the heat transfer capability of the sintered core and expanding an applicable environment.

Owner:YANGZHOU UNIV

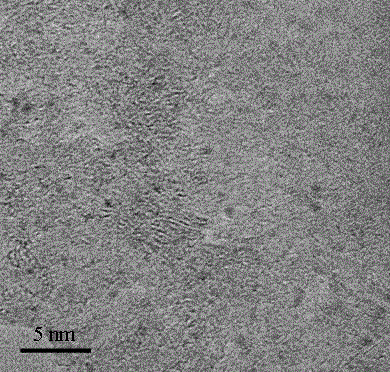

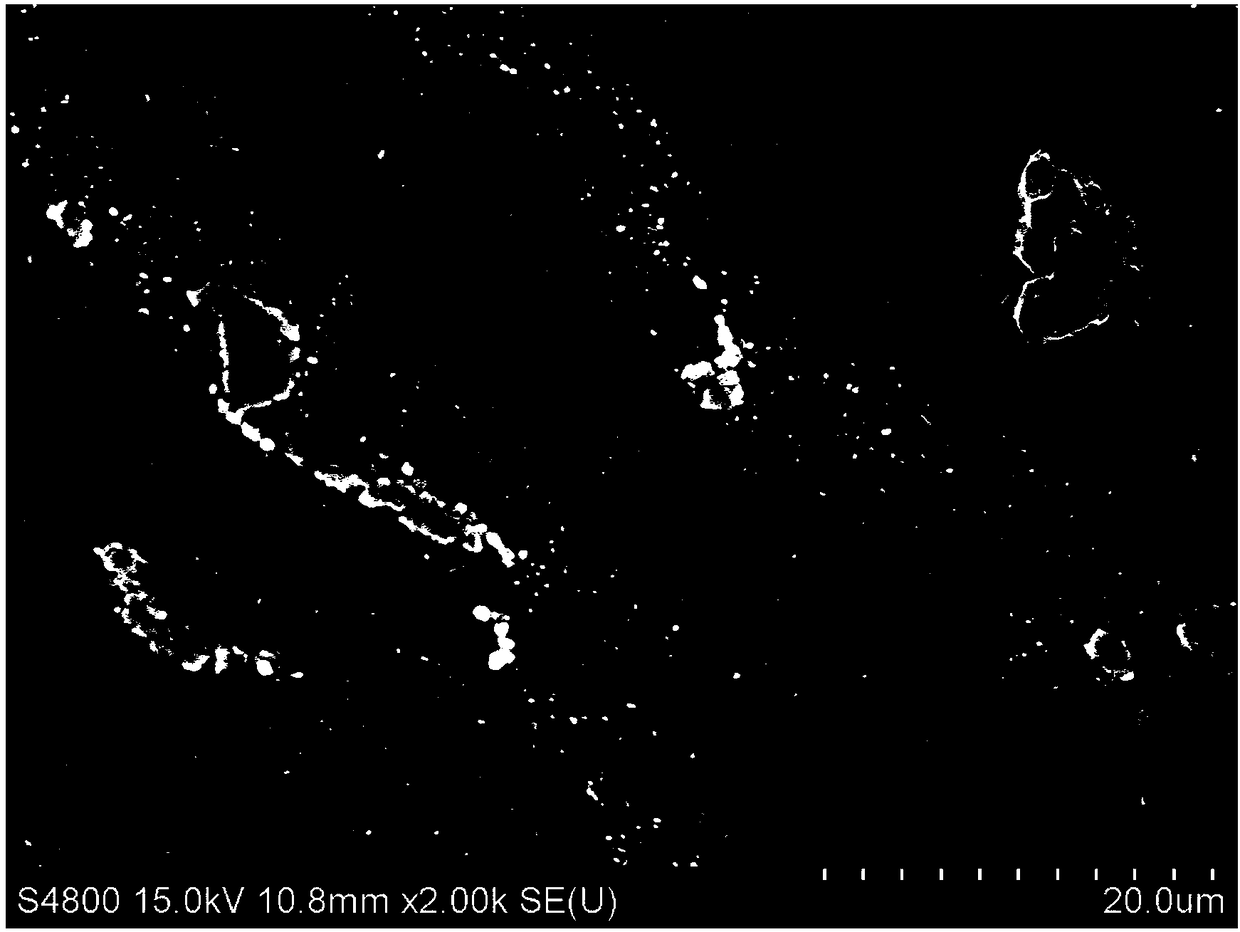

Preparation method of nano carbon based loaded two-dimensional noble metal cluster composite material

InactiveCN105289591AImprove performanceStrong particle sizeCell electrodesCatalyst activation/preparationOxygenUltrasonic dispersion

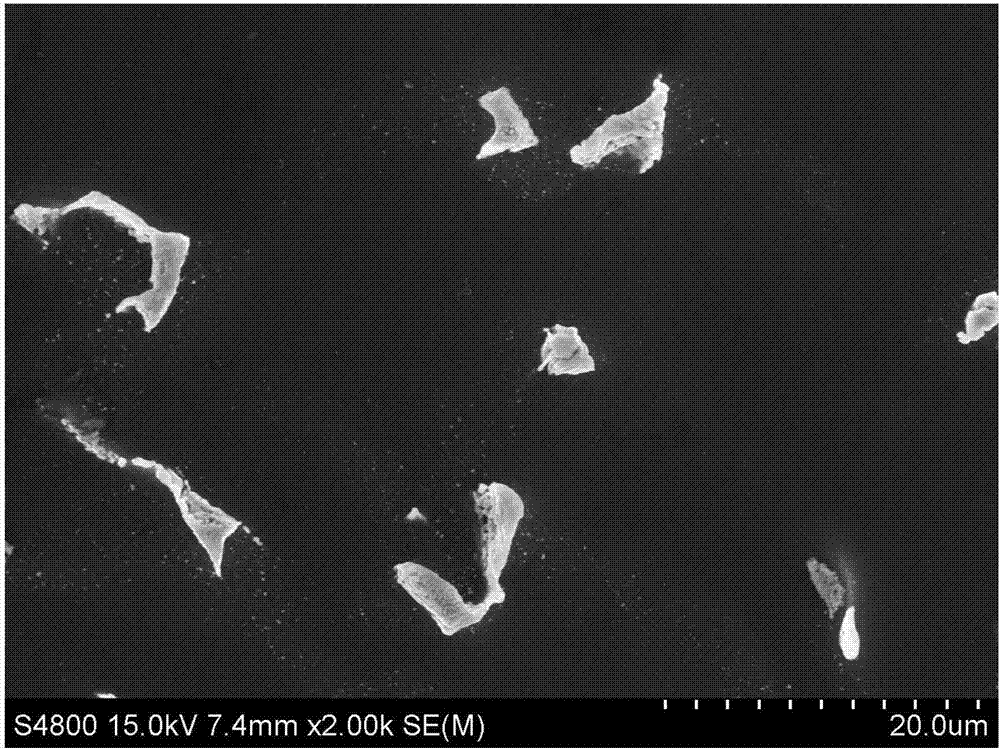

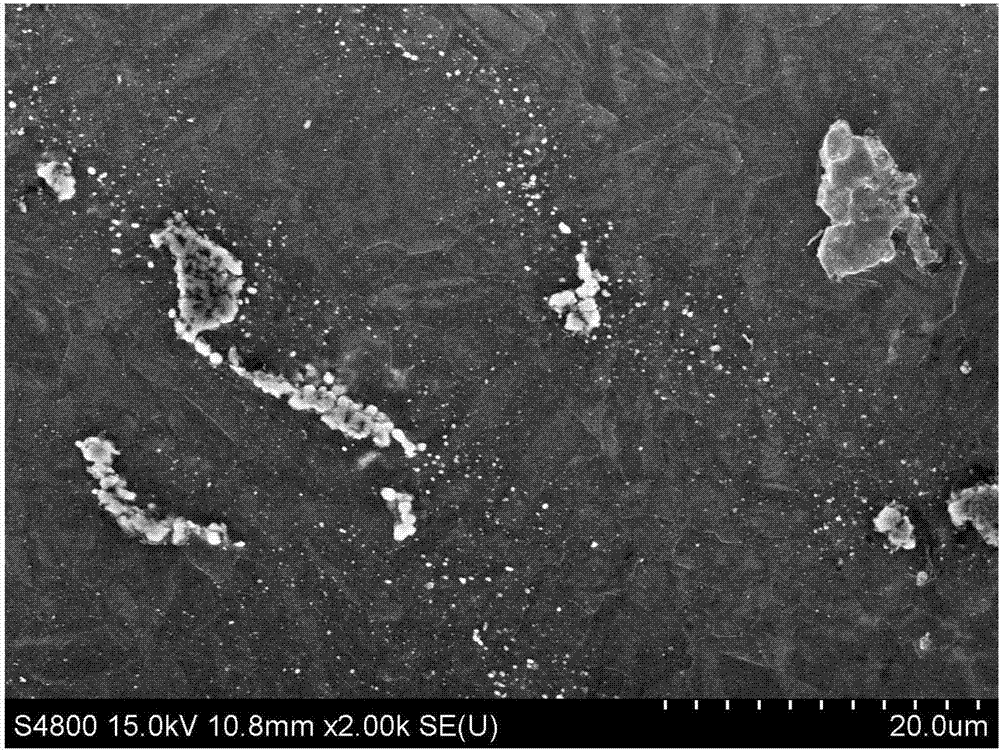

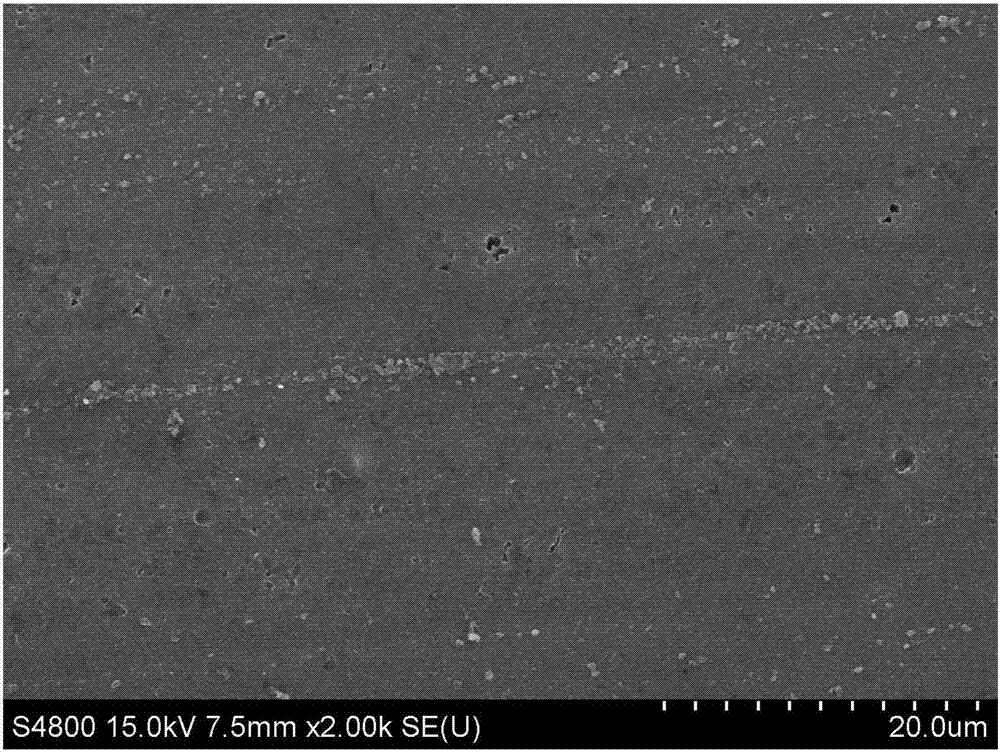

The invention discloses a preparation method of a nano carbon based loaded two-dimensional noble metal cluster composite material. According to the invention, nano carbon refers to nano carbon black. The method comprises the following steps: immersing the carbon black into a mixed solution of sulfuric acid and ammonium persulfate, and oxidizing the surface of the carbon black to carry an oxygen-containing radical; carrying out ultrasonic dispersion on a carbon black water solution subjected to oxidization treatment to form a carbon black suspension solution; dripping the carbon black suspension solution to the surface of a glass electrode and slowly drying; immersing the glass electrode into a Pb<2+> solution for a period of time and carrying out exchange reaction on Pb<2+> and the oxygen-containing radical on the surface of the carbon black; adsorbing the Pb<2+> to the surface of the carbon black through the oxygen-containing radical on the surface of the carbon black; carrying out electrochemical reduction on the glass electrode and reducing the Pb<2+> into PbO; immersing the glass electrode into a solution of noble metal ions so as to carry out replacement reaction on the noble metal ions and the PbO; and finally, depositing a two-dimensional noble metal cluster on the surface of the carbon black. The nano carbon based loaded two-dimensional PtRu cluster composite material prepared by the invention has ultrahigh catalytic activity on methanol oxidation reaction; and according to the invention, preparation methods of the nano carbon based composite material are hopeful to enrich, the structure of the material is optimized and the performance of the material is improved.

Owner:HUNAN UNIV OF TECH

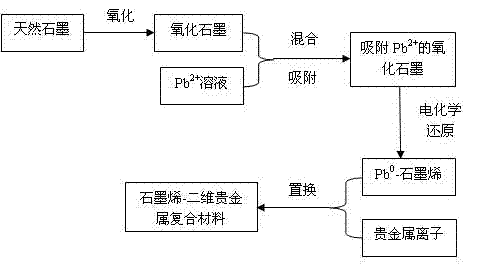

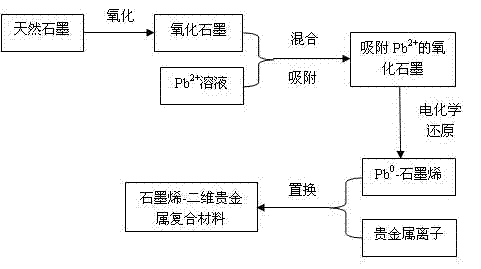

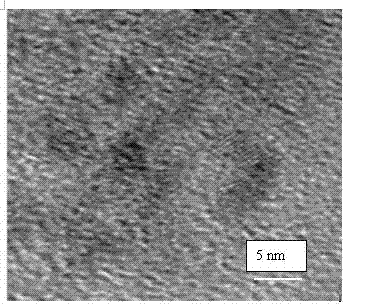

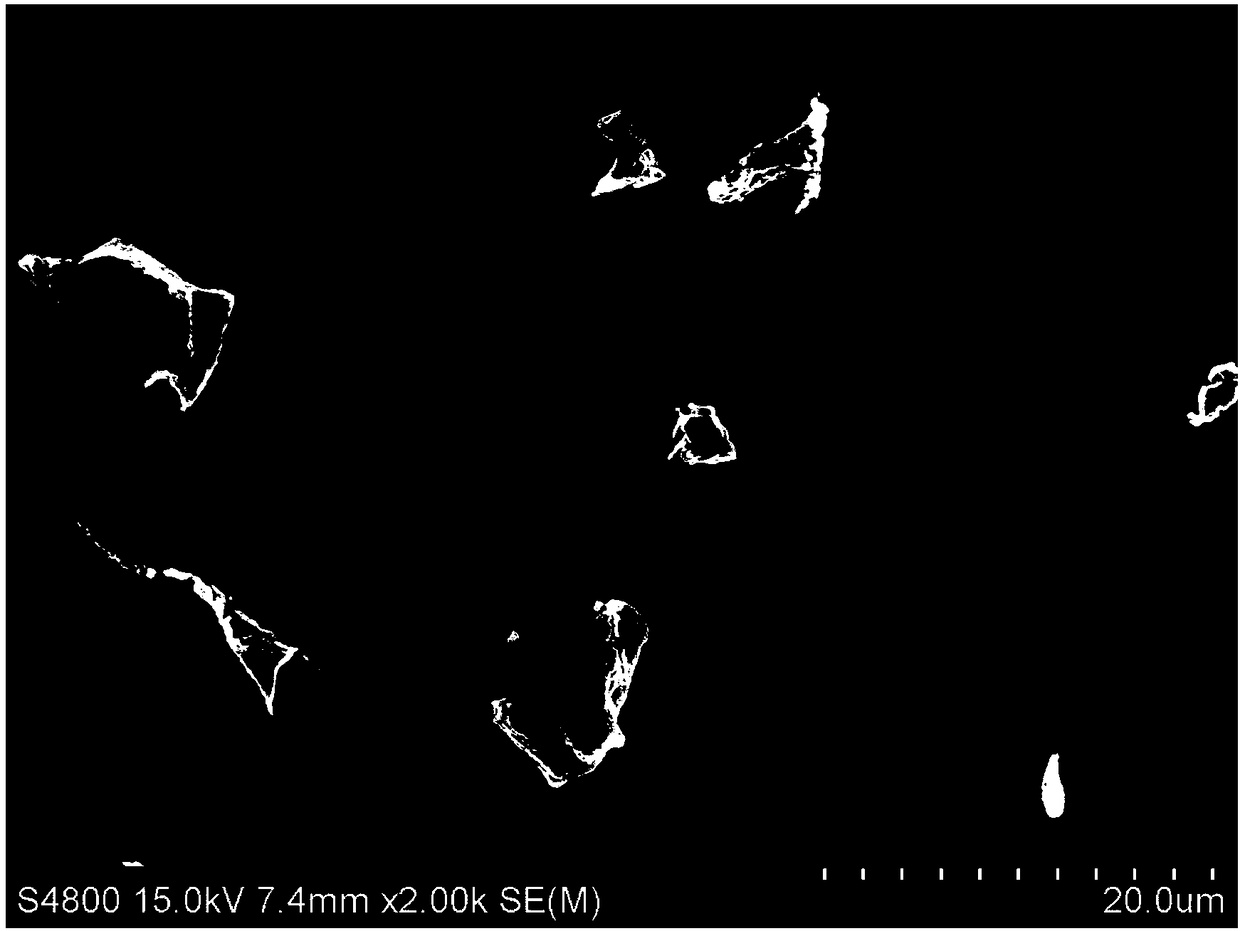

Method for manufacturing graphene-two-dimensional precious metal atomic layer composite materials

InactiveCN103521220AImprove performanceLarge particle sizeMetal/metal-oxides/metal-hydroxide catalystsElectrochemistryUltrasonic dispersion

The invention discloses a method for manufacturing graphene-two-dimensional precious metal atomic layer composite materials. The method comprises the following steps that ultrasonic dispersion is carried out on graphite oxide in aqueous solutions, graphene oxide solutions are formed and are dropped on the surface of a glass electrode, and the grapheme oxide solutions are dried gradually; the glass electrode is submerged in Pb2+solutions for a while, Pb2+ and graphene oxide generate an exchange reaction, and the Pb2+ is absorbed to the surface of the graphene oxide; electrochemical reduction is carried out on the glass electrode, the Pb2+ is reduced into Pb0, and meanwhile the graphene oxide is reduced into grapheme; then the glass electrode is submerged in the solutions of precious metal ions, the precious metal ions and the Pb0 generate a replacement reaction, and the graphene-two-dimensional precious metal atomic layer composite materials are obtained. The manufactured graphene-two-dimensional PtRu composite materials have ultrahigh catalytic activity on the oxidizing reaction of methanol, and the root lies in the strong coupling of the grapheme and two-dimensional precious metal atoms. The method is expected to enrich the manufacturing method of grapheme composite materials, to optimize the structure of the grapheme composite materials, to improve the performance of the grapheme composite materials and to widen the application range of the grapheme composite materials.

Owner:HUNAN UNIV OF TECH

Fishy smell free fish glue and preparation method thereof

InactiveCN107668565ASolve the problem of fishy smellEasy to productizeFood scienceFruit juiceVitamin C

The present invention discloses fishy smell free fish glue and a preparation method thereof and belongs to the technical field of food processing. The fish glue comprises the following components: 20-60% of fish glue raw materials, 5-10% of soybean milk, 8-12% of concentrated fruit juice, 0.5-1.5% of vitamin C, 0.1-0.5% of citric acid, 0.01-0.05% of a fruit essence and the balance water. The fishglue is reasonable in the components and clear in preparation principles. Washing and multiple soaking are conducted to remove a fishy smell of the fish glue. A penetration seasoning method is conducted to enable the fish glue to have loved tastes by consumers. Compared with preparation methods of traditional fish glue products, the preparation method solves a problem of a fishy smell of the fishglue, reduces difficulties of cooking in a later period, and further promotes productization and marketization of the fish glue.

Owner:镇江中一广告制品有限公司

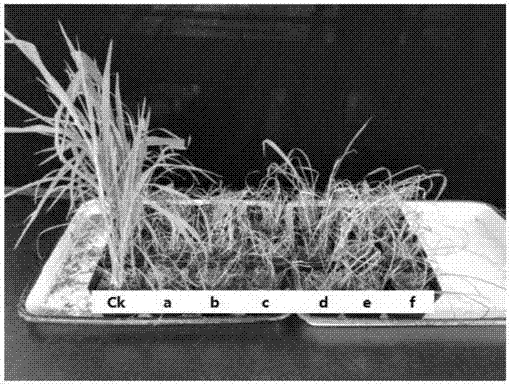

Cyhalofop-butyl emulsion in water and preparation method thereof

The invention relates to a cyhalofop-butyl emulsion in water and a preparation method thereof and belongs to the technical field of herbicides. The cyhalofop-butyl emulsion in water is prepared from the following raw materials in percentages by mass: 6-12% of cyhalofop-butyl, 8-15% of a solvent, 6-15% of an emulsifier, 2-6% of an antifreezing agent and the balance of water. The cyhalofop-butyl emulsion in water provided by the invention is reasonable in component and clear in preparation principle. The efficient and environment-friendly emulsion in water is prepared by means of a low energy emulsion process, so that the processing flow is simplified, the production cost is lowered, and the product stability and the weed control effect are improved. Meanwhile, depositing, diffusing and permeating properties of a medicine liquid on the surface of a target are improved, and the efficacy is further improved.

Owner:YANGZHOU UNIV

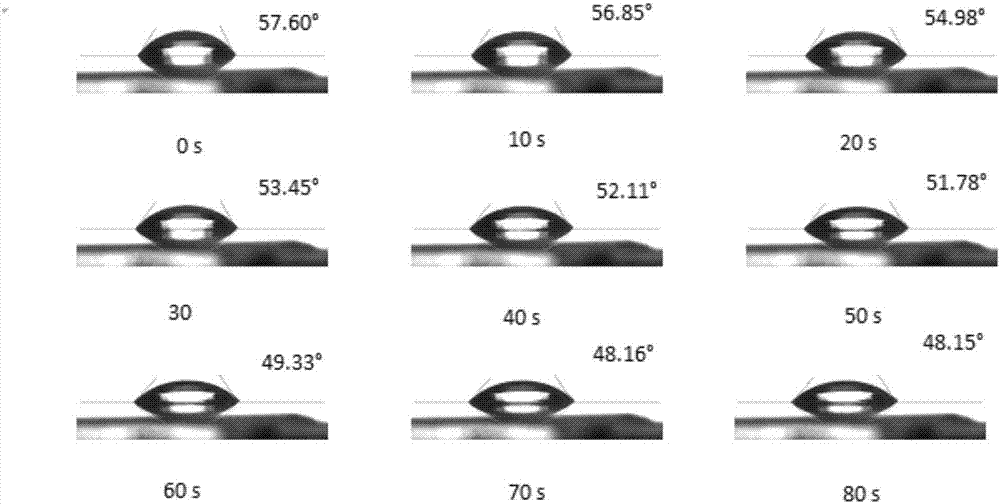

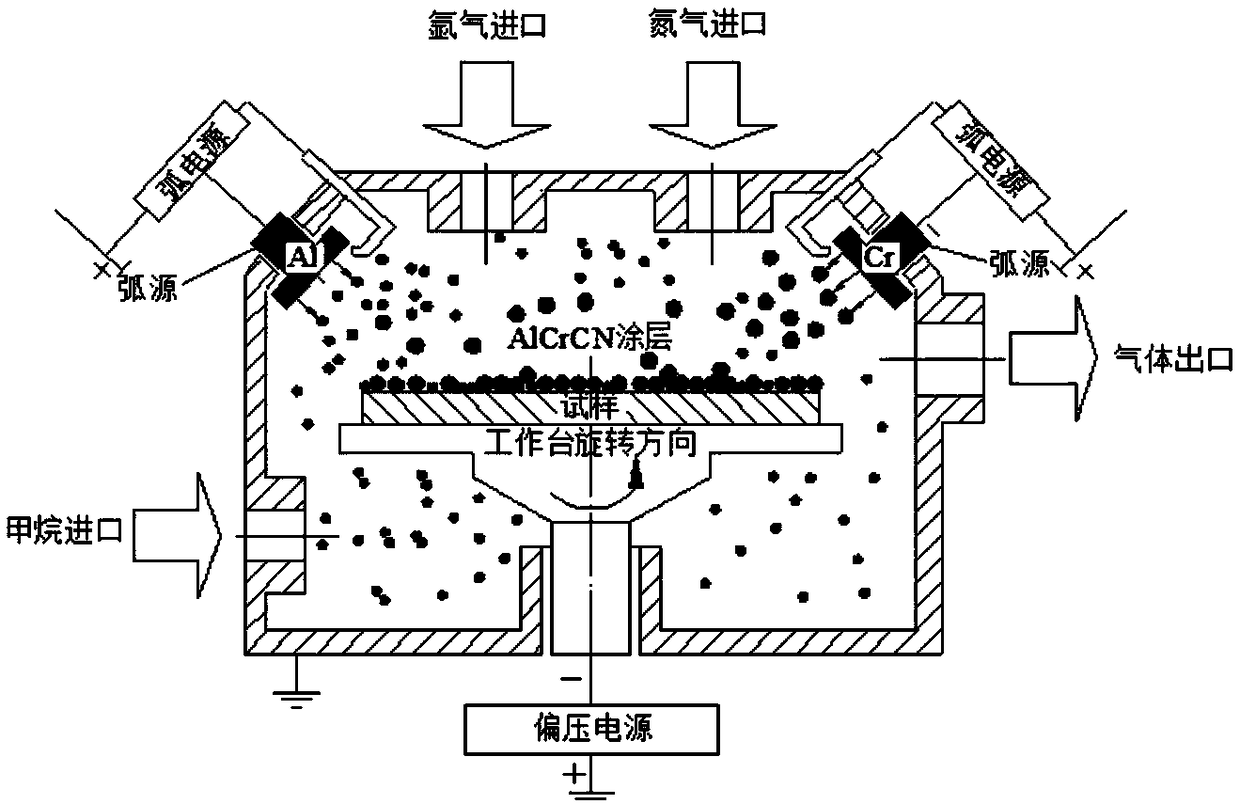

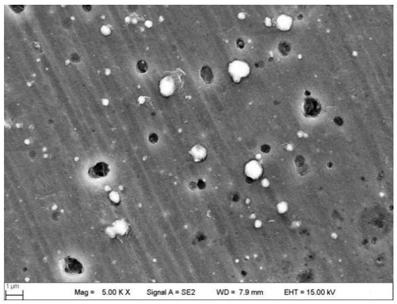

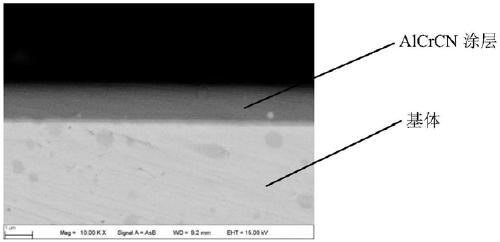

Method for preparing AlCrCN coating on surface of cold working die steel

InactiveCN109252140AClear precisionGood for maintaining accuracyVacuum evaporation coatingSputtering coatingMaterials preparationDeposition temperature

The invention discloses a preparation method for preparing an AlCrCN coating on the surface of a cold working die steel, and belongs to the technical field of material preparation, wherein the methodis scientific, and the preparation principle is clear. According to the present invention, ion plating is performed at a temperature of 500 DEG C, such that the deposition temperature cannot cause mold deformation, and the precision of the mold is easily maintained; the harness of the prepared coating is 3500 HV, such that the surface hardness of the mold is increased, the wear of the mold is reduced, and the quality of the processed work-piece is ensured; the AlCrCN coating and the substrate form the diffusion layer at the interface bonding position, and the elements of the diffusion layer are transitioned into the gradient, such that the bonding of the coating and the substrate is good; the amorphous C-C bond is formed in the AlCrCN coating, such that the self-lubricating effect is achieved so as to effectively reduce the friction factor; and the AlCrCN coating has advantages of ultra-high hardness, low friction factor, wear resistance and the like so as to further improve the surface hardness of the cold working die steel and prolong the service life by 3-5 times.

Owner:YANGZHOU UNIV +1

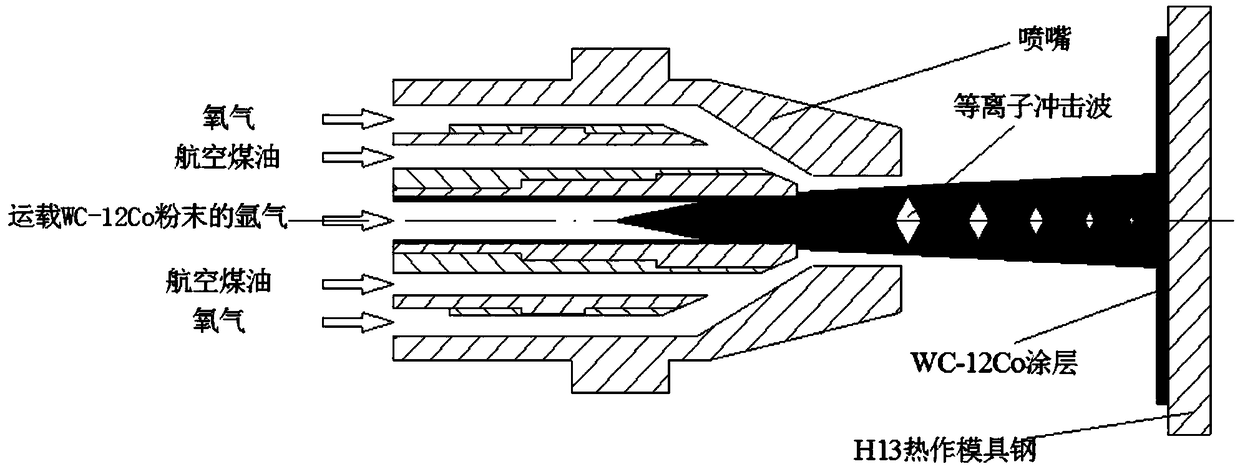

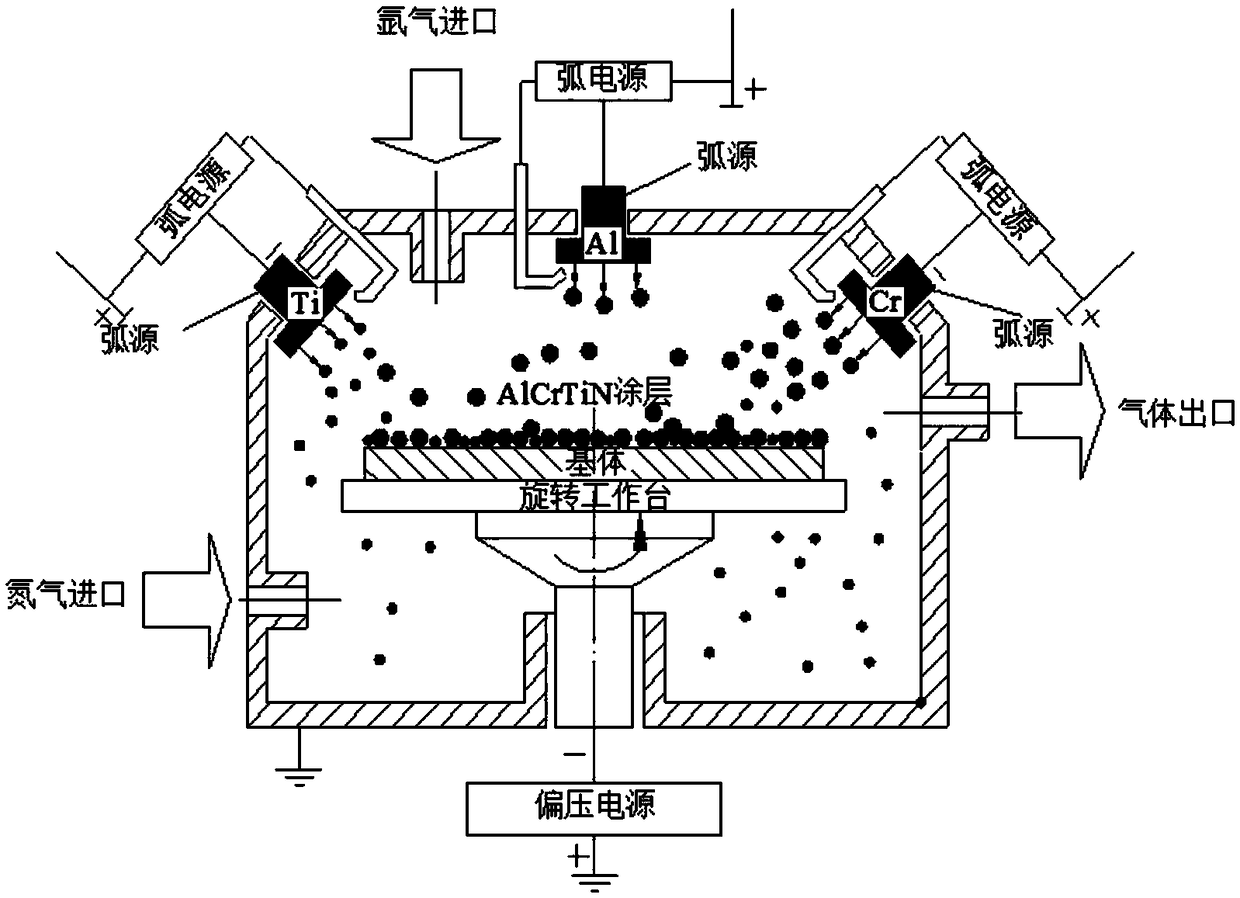

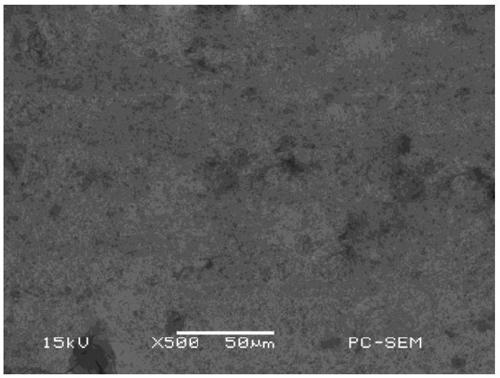

Method for preparing AlCrTiN/WC-12Co composite coating on surface of hot-work die steel

InactiveCN109161835AHigh surface hardnessLower hardness gradientMolten spray coatingVacuum evaporation coatingSpray coatingHeat stability

The invention relates to a method for preparing an AlCrTiN / WC-12Co composite coating on the surface of hot-work die steel, and belongs to a material surface modified composite treatment technology. The method is scientific and clear in preparation principle. The WC-12Co coating is prepared by spray-coating the surface of H13 hot-work die steel with hypersonic flame, so that the surface hardness ofthe matrix is increased, the wear resistance of particles is enhanced, the hardness gradient between the coating and the matrix is reduced and guarantee is provided for the use of an AlCrTiN coating.The AlCrTiN coating is prepared by plating the surface of the WC-12Co coating with cathode ions, the AlCrTiN / WC-12Co composite coating prepared by the method is obtained and has a nitride phase witha cubic structure, and the surface hardness, the oxidation resistance and the heat stability are further improved.

Owner:YANGZHOU UNIV +1

Steel pipe anti-corrosion composite coating and preparation method thereof

InactiveCN107880720AImprove high temperature resistanceImprove wear resistanceConjugated diene hydrocarbon coatingsAnti-corrosive paintsEpoxyIon permeation

The invention discloses a steel pipe anti-corrosion coating and a preparation method thereof, and belongs to the technical field of chemical materials. The steel pipe anti-corrosion coating is prepared from, by weight, 5-12% of pigment, 3-8% of filler, 8-12% of dispersing agent, 6-12% of coalescing agent, 5-8% of defoaming agent, 2-6% of polyphenyl ether resin powder, 5-8% of butadiene styrene rubber, 3-6% of methylbenzene, 1-3% of plasticizer, 1-3% of coupling agent, 2-4% of auxiliaries, 1-3% of fire retardant, 2-4% of white carbon black, and the balance organosilicone modified epoxide resin.The preparation principle is clear, the method is scientific, the organosilicone modified epoxide resin has the advantages of being high in adhesive property, good in chemical reagent resistance andthe like, modified epoxy can enhance the water and ion permeation resistance of the coating, and the binding force between a metallic matrix and the coating is improved, so that the coating protectivecapability is improved, the high temperature resistance and the wear resistance of a steel pipe are enhanced, and the using safety of the steel pipe is greatly improved.

Owner:靖江市新东机械零部件制造有限公司

Foamed material with insulation and preparation method thereof

InactiveCN107722229AReduce Shrinkage ProblemsAvoid deformationDichlorodifluoromethanePolymer science

The invention provides a foamed material with insulation and a preparation method thereof, and belongs to the technical field of foamed material preparation. The material comprises the following raw materials in percentages by weight: 40-50% of toluene diisocyanate, 15-20% of polyether polyol, 3-6% of expanded vermiculite, 1-3% of silica, 2-8% of dichlorodifluoromethane, 2-8% of an organic pigment, 2-8% of a catalyst, 1-3% of a foam stabilizer, and the balance being water. The preparation method has intelligible principle and simple processing method, and compared with foamed materials prepared by traditional methods, the product has more excellent compressive strength, tensile strength and impact strength; in addition, compared with the prior art, the polyurethane foam insulation materialhas high thermal insulation performance of common polyurethane foamed materials, and the problem of foam shrinkage caused by itself characteristics, production process, production worker operation ability and other aspects are is reduced, and the phenomenon of deformation, bulge, barring, even cracking of water tanks is avoided.

Owner:江苏晶王新材料科技有限公司

Cement grinding aid with high agglomeration performance and preparation method thereof

The invention discloses a cement grinding aid with high agglomeration performance, and belongs to the technical field of building materials. The cement grinding aid is prepared from the following rawmaterials in percentage by weight: 5-10% of diesel oil, 1-3% of methyl alcohol, 1-3% of nekal, 3-5% of polymeric alkylol amine, 3-8% of glycol, 5-12% of triethanolamine, 3-5% of molasses, 1-6% of sodium phosphate, 1-3% of sodium lignin sulfonate, 5-20% of sorbitol, 5-20% of sodium thiocyanate, and the balance of water. Through stirring, dissolving and still standing, the cement grinding aid is obtained. The preparation principle is clear, a method is scientific, compared with the prior art, the production cost is lower, a production process is simple, the admixture amount is low, the enhancement effect is good, the agglomeration performance of cement can be improved, the output of the cement can be increased, and the cement grinding aid is suitable for large-scale production.

Owner:刘晓英

Preparation method for night self-luminous mobile phone shell

InactiveCN107974181AThe principle of preparation is clearMethod sciencePolyurea/polyurethane coatingsTelephone set constructionsLacquerMobile phone

The invention relates to a preparation method for a night self-luminous mobile phone shell, and belongs to the technical field of electronic products. The preparation method comprises the following steps: mixing a plastic substrate, fluorescent powder and a dye according to a proportion, carrying out stirring to obtain a mixture, heating and melting the mixture to obtain a liquid material, throwing the liquid material into a screw extruder, feeding the material in the screw extruder into an injection molding machine through a pressurizing pump, injecting the material into a mobile phone mold for molding; sequentially spraying a primer and a colored paint, then carrying out vacuum coating, and removing the vacuum coated film in an area, where a colored paint layer needs to be displayed, onthe vacuum coating layer by laser radium carving. After the vacuum coating, a middle paint layer and a UV surface paint layer are sequentially formed on the surface of the coating film. The preparation theory is clear; the method is scientific; the mobile phone shell prepared by the method provided by the invention has exquisite texture, rich color, good color gradation and good visual effect; themobile phone is convenient to find at night; and convenient use for people is obtained.

Owner:芜湖辉灿电子科技有限公司

Preparation method for carbon fixation and emission reduction green potassium fertilizer

InactiveCN108467310AThe principle of preparation is clearAbundant raw materialsAnimal corpse fertilisersBioloigcal waste fertilisersFertilizerChemistry

The invention relates to a preparation method for a carbon fixation and emission reduction green potassium fertilizer, and belongs to the technical field of fertilizer preparation. The preparation ofthe potassium fertilizer is completed by preparing a biochar material and preparing, fermenting, drying and pulverizing a biochar composite material, and the preparation principle is clear; compared with a traditional potassium fertilizer preparation method, the method is diversified in raw materials, provides convenience for capturing carbon elements in the soil, achieves long-term supply of potassium sources, and meets the requirements of green agriculture.

Owner:江苏盛禾资源环境科技有限责任公司

Brewed dried fish gelatin instant food and making method thereof

The invention discloses a brewed dried gelatin instant food and a making method thereof and belongs to the technical field of food processing. The brewed dried gelatin instant food comprises the following components: 20%-60% of gelatin powder, 5%-10% of fruit granules, 0.5%-1.5% of dried petals, 2%-8% of milk powder, 0.5%-1.5% of vitamin C, 0.1%-0.05% of citric acid, 0.01%-0.05% of fruit essence and 0.5%-2% of granulated sugar. The brewed dried gelatin instant food is reasonable in component and clear in preparation principle, the fish smell of fish gelatin is removed through cleaning and multi-stage soaking, the fish gelatin and other auxiliary materials are dehydrated through microwave treatment and vacuum drying, compared with a conventional fish gelatin product, the brewed dried gelatin instant food disclosed by the invention is very convenient to carry over and take, low in processing cost and small in fish smell and can be rapidly brewed and taken instantly, and thus productization and marketization of fish gelatin are further promoted.

Owner:江苏晶王新材料科技有限公司

Processing method of antistatic powder coating

InactiveCN107805458AAntibacterialMeet antistaticAntifouling/underwater paintsPaints with biocidesDissolutionPrecipitation

The invention discloses a processing method of an antistatic powder coating and belongs to the technical field of chemical coatings. The processing method comprises the following steps: adding a sodium hydroxide aqueous solution into a silver nitrate solution with the volume of 0.005 mol / L to form a mixed solution; stirring the mixed solution, and instilling dilute ammonia water into the stirred mixed solution; carrying out precipitation-dissolution to obtain a Tollen reagent; preparing a mixture by mixing the following components in percentage by weight: 10 percent of modified resin, 2 percent of kaolin, 2 percent of a dispersing agent, 2 percent of white carbon black, 0.5 percent of a surfactant, 2 percent of a modifier and 0.5 percent of calcium carbonate; carrying out grinding, drying,crushing and the like on the mixture and finally obtaining the antistatic powder coating. The processing method of the antistatic powder coating, disclosed by the invention, adopts a clear preparation principle and scientific components; compared with traditional powder coating, the antistatic powder coating prepared by the processing method disclosed by the invention has the advantages that antibacterial and antistatic properties are realized, the safety use demands of the powder coating are met, the safety performance of the powder coating is improved, potential safety hazards are reduced as well as personal injury and property loss are reduced.

Owner:靖江市新东机械零部件制造有限公司

Printing ink with high stability and preparation method thereof

The invention discloses a printing ink with high stability, and belongs to the technical field of printing; the printing ink consists of the following raw materials by the weight percentage: 10-20% ofmodified alkyd resin, 2-6% of kaolin, 2-6% of a dispersant, 2-6% of white carbon black, 0.8-1.8% of a pigment, 0.5-2.8% of a surfactant, 0.6-2.6% of a talcum powder, 2-6% of ethanol, 2-6% of isopropanol, 2-4% of a regulator, and the balance water. The preparation principle is clear and the components are scientific. Compared with a traditional printing ink, the prepared printing ink is nontoxic and smell-less, is suitable for various types of gravure and rotary flexo printing processes, and has good transferability and fastness to adhesion; a mixed solvent is prepared from a variety of liquids in the ink, so that the ink is mixed evenly, has high gloss of a printing ink layer, has good transparency and water resistance, meets the environmental-protection use requirements for the printingink and improves the adhesion and drying performance of the printing ink.

Owner:靖江市新东机械零部件制造有限公司

Corrosion-resisting coating for old steel tube and operation method of corrosion-resisting coating

InactiveCN107936703AThe principle of preparation is clearMethod scienceFireproof paintsConjugated diene hydrocarbon coatingsSteel tubePlasticizer

The invention discloses a corrosion-resisting coating for an old steel tube and an operation method of the corrosion-resisting coating, and belongs to the technical field of metallic surface treatment. The coating is prepared from the following raw materials in percentage by weight: 1 to 3 percent of asphalt, 2 to 6 percent of a dispersing agent, 8 to 15 percent of graphene, 2 to 6 percent of a polyphenyl ether resin powder, 3 to 9 percent of styrene-butadiene rubber, 3 to 6 percent of methylbenzene, 1 to 3 percent of a plasticizer, 1 to 3 percent of a coupling agent, 2 to 4 percent of auxiliary materials, 1 to 3 percent of flame retardant and the balance of water. The corrosion-resisting coating for the old steel tube, disclosed by the invention, adopts a clear preparation principle and ascientific method; the surface of the old steel tube is cleaned by abrasive blasting, shot blasting and high-pressure water jetting, and then corrosion-resisting coating materials are combined with the steel tube by adopting a coating mode to form an integrated structure, wherein the asphalt has the advantages of high adhesion, good chemical reagent resistance and the like; in addition, the graphene has higher hardness, higher strength and heat resistance, so that the protective ability of the coating is improved, high-temperature resistance of the steel tube is enhanced, the use safety of the steel tube is greatly improved and use demands of special occasions are met.

Owner:靖江市新东机械零部件制造有限公司

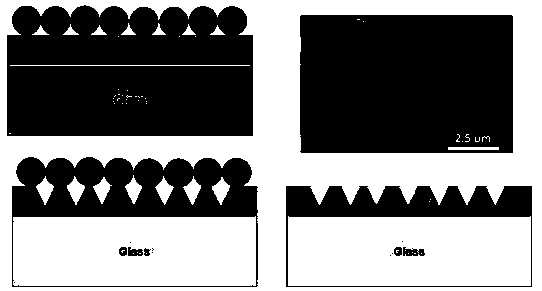

An OLED with a micrometer periodic structure ITO electrode and a preparation method thereof

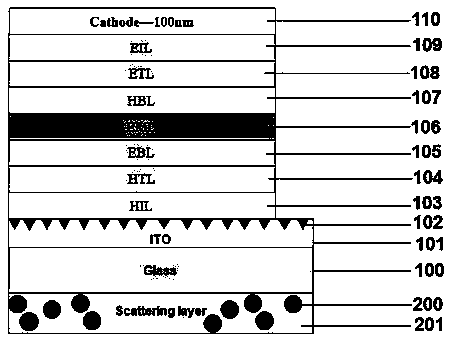

InactiveCN109244267ANovel structureThe principle of preparation is clearSolid-state devicesSemiconductor/solid-state device manufacturingMicrometerBatch production

The invention relates to an OLED with a micrometer periodic structure ITO electrode and a preparation method thereof, and belongs to the technical field of OLED production and manufacture. An ITO layer, a micrometer periodic structure layer, a hole injection layer, a hole transport layer, an electron barrier layer, a light emitting layer, a hole barrier layer, an electron transport layer, an electron injection layer and a metal electrode layer are sequentially arranged on the front surface of a glass substrate. A scattering layer and a curing layer are sequentially arranged on the back surfaceof the glass substrate. The OLED of the invention has novel structure and clear preparation principle, and the ITO micron periodic structure is prepared by using SiO2 micro-nano diameter ball as ICP-RIE mask complete, Prior to evaporation of the organic light-emitting layer, the surface of ITO was treated by water-gas two-fluid of H2O2 and CO2, the work function of ITO surface is increased to about 5.3 V, In order to improve the injection efficiency of electron holes, the scattering layer formed on the glass substrate is by ultraviolet curing optical adhesive (NOA73) glue and SiO2 micro-nanodiameter spheres is coated and solidified on the glass substrate. The luminescent efficiency can be improved by 10-20%. The process foundation is mature and the raw materials are easy to obtain, which is conducive to batch production.

Owner:肖和平

Grinding aid for improving flow property of mineral aggregate

InactiveCN110407505AImprove efficiencyImprove production efficiencyAnhydrous ethanolSodium thiocyanate

The invention discloses a grinding aid for improving the flow property of mineral aggregate, and belongs to the technical field of building materials. The grinding aid is prepared from the following raw materials in percentage by weight: 5-10% of anhydrous ethanol, 3-8% of ethylene glycol, 1-3% of methanol, 1-3% of sodium dibutylnaphthalenesulfonate, 3-5% of polymeric alkylol amine, 5-12% of triethanolamine, 3-5% of white sugar, 1-6% of sodium phosphate, 1-3% of sodium lignosulfonate, 5-20% of sorbitol, and 5-20% of sodium thiocyanate. The grinding aid has a clear preparation principle, a method is scientific, compared with the prior art, the production cost of the grinding aid is lower, the production process is simpler and the mixing amount is low and the reinforcing effect is good, theflow property and production efficiency of the mineral aggregate can be improved, and the grinding aid is suitable for large-scale production.

Owner:刘晓英

Rapidly-moulded PET engineering plastic and preparation method thereof

InactiveCN107541029AThe principle of preparation is clearSimple processing methodChemistryFire retardant

The invention discloses rapidly-moulded PET engineering plastic and a preparation method thereof, and belongs to the technical field of preparation of engineering plastic. The rapidly-moulded PET engineering plastic comprises the following raw materials in percent by weight: 40-50% of a PET waste raw material, 15-20% of modified glass fiber, 3-7% of a flame retardant, 5-10% of a crystallizing nucleating agent, 3-5% of a lubricating agent, 2-5% of an antioxidant, 2-4% of a chain expander and the balance of water. The preparation principle of the invention is clear; a processing method is simple; due to difficulty in moulding processing, the PET crystallization speed is improved, the plasticizing and toughening effects are achieved and further the using performance is further improved.

Owner:江苏晶王新材料科技有限公司

Method for manufacturing graphene-two-dimensional precious metal atomic layer composite materials

InactiveCN103521220BImprove performanceLarge particle sizeMetal/metal-oxides/metal-hydroxide catalystsElectrochemistryGlass electrode

The invention discloses a preparation method of a graphene-two-dimensional precious metal atomic layer composite material. The method consists of the following steps: ultrasonically disperse graphite oxide in an aqueous solution to form a graphene oxide solution, drop it on the surface of a glass electrode, and wait for it to dry slowly; immerse the glass electrode in a Pb2+ solution for a period of time, Pb2+ and graphite oxide ene exchange reaction, Pb2+ is adsorbed on the surface of graphene oxide; the glass electrode is electrochemically reduced, Pb2+ is reduced to Pb0, and graphene oxide is reduced to graphene at the same time; then the glass electrode is immersed in the solution of noble metal ions to make the noble metal ions A displacement reaction occurs with Pb0 to obtain a graphene-two-dimensional noble metal atomic layer composite material. The graphene-two-dimensional PtRu composite material prepared by the present invention has ultra-high catalytic activity for methanol oxidation, which is rooted in the strong coupling between graphene and two-dimensional noble metal atoms. The invention is expected to enrich the preparation method of the graphene composite material, optimize its structure, improve its performance and expand its application range.

Owner:HUNAN UNIV OF TECH

A kind of preparation method of biomedical magnesium alloy wire

ActiveCN106917022BImprove corrosion resistanceThe principle of preparation is clearZinc alloysLiquid metal

Owner:YANGZHOU UNIV

Method for preparing modified cement grinding aid

InactiveCN110407500AImprove the lubrication effectImprove performanceSodium thiocyanateCement grinding

The invention discloses a method for preparing a modified cement grinding aid and belongs to the technical field of building materials. The modified cement grinding aid is prepared from the followingraw materials in percentage by weight: 6-10% of polymeric alkylol amine, 5-8% of glycerinum, 3-20% of ethylene glycol, 3-10% of triethanolamine, 15-20% of tri-isopropanolamine, 5-20% of sorbitol, 5-20% of sodium thiocyanate and the balance of water. The cement grinding aid is prepared through stirring, dissolving and standing. The preparation principle is clear, the method is scientific, comparedwith the prior art, the cement grinding aid is low in mixing amount, good in reinforcement effect and capable of improving properties of cement and increasing machine-hour yields, properties of the cement grinding aid can be excellent, the lubrication degree of the cement can be remarkably improved, the flowability of the cement can be improved, and the method is simple in production process, lowin cost and applicable to on-scale production.

Owner:刘晓英

A flip-chip algainp red light micro-led and its preparation method

The invention belongs to the technical field of LED production and manufacture, and relates to a flip-chip structure AlGaInP red light Micro-LED and a preparation method thereof. The flip-chip structure AlGaInP red light Micro-LED includes an n-GaAs ohmic contact layer 101, an n-AlGaInP expansion layer 102, a DBR layer 103, an n-AlInP confinement layer 104, a light emitting layer 105, a p- AlInP confinement layer 106, a p- AlGaInP extended layer 107, a p-GaP current spread layer 108, a p-GaP ohmic contact lay 109, a p-GaP coarse bonding lay 110, an ITO layer 200, a cured layer 300, a substrate400, an electrode layer 501, a first metal layer 502, a protective layer 600, an ODR layer 601 and a second metal layer 700 ; the structure is novel, the working principle is clear, and the light emitting efficiency is improved; As that bonding layer between indium tin oxide (ITO) and the ultraviolet cure optical adhesive is used as a bonding layer connecting the sapphire, the bonding yield can be improved, and the technical route of the invention is reliable, the technical foundation is mature, the raw materials are easy to obtain, and the invention is favorable for batch production.

Owner:肖和平

High wear resistance composite paint and preparation method thereof

The invention discloses high wear resistance composite paint and a preparation method thereof, and belongs to the technical field of paint preparation. The composite paint comprises the following rawmaterials in percent by weight: 1 to 6 percent of water-emulsion synthetic resin, 2 to 6 percent of methyl acrylate, 8 to 15 percent of an initiator, 2 to 6 percent of polyphenyl ether resin powder, 3to 9 percent of talcum powder, 3 to 6 percent of barium sulfate, 1 to 3 percent of lime powder, 1 to 3 percent of sodium benzoate, 2 to 4 percent of a conditioning agent, and the balance of water. The composite paint is clear in preparation principle and scientific in components, and compared with the traditional composite materials, the composite paint has the advantages that the corresponding hardness of a coating layer can be enhanced, the composite paint is not likely to pulverize and fall off when in use, and the subsistent problems in the traditional technology are remedied.

Owner:靖江市新东机械零部件制造有限公司

Environment-friendly composite coating and preparation method thereof

InactiveCN107828336AMake up for pinholesMake up for blisteringNatural resin coatingsPolyether coatingsEmulsionMetallurgy

The invention discloses an environment-friendly composite coating and a preparation method thereof, and belongs to the technical field of coating preparation. The coating is prepared from the following raw materials in percentage by weight: 1 to 3 percent of water emulsion-based synthetic resin, 2 to 6 percent of a dispersing agent, 8 to 15 percent of water-based high gloss varnish, 2 to 6 percentof polyphenyl ether resin powder, 3 to 9 percent of talcum powder, 3 to 6 percent of barium sulphate, 1 to 3 percent of lime powder, 1 to 3 percent of sodium benzoate, 2 to 4 percent of ethylene glycol, 1 to 3 percent of a flame retardant and the balance of water. The environment-friendly composite coating is clear in preparation principle and scientific in components; compared with the conventional composite material, the composite coating prepared by the preparation method is more environment-friendly; the defects, such as needle holes, bubbles, cracks and peeling, of the composite coatingare effectively filled; the using requirement of environment friendliness of the composite coating is met; and the defects and the disadvantages of the composite material are filled.

Owner:靖江市新东机械零部件制造有限公司

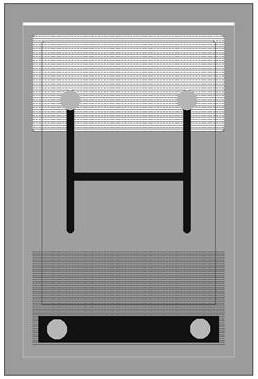

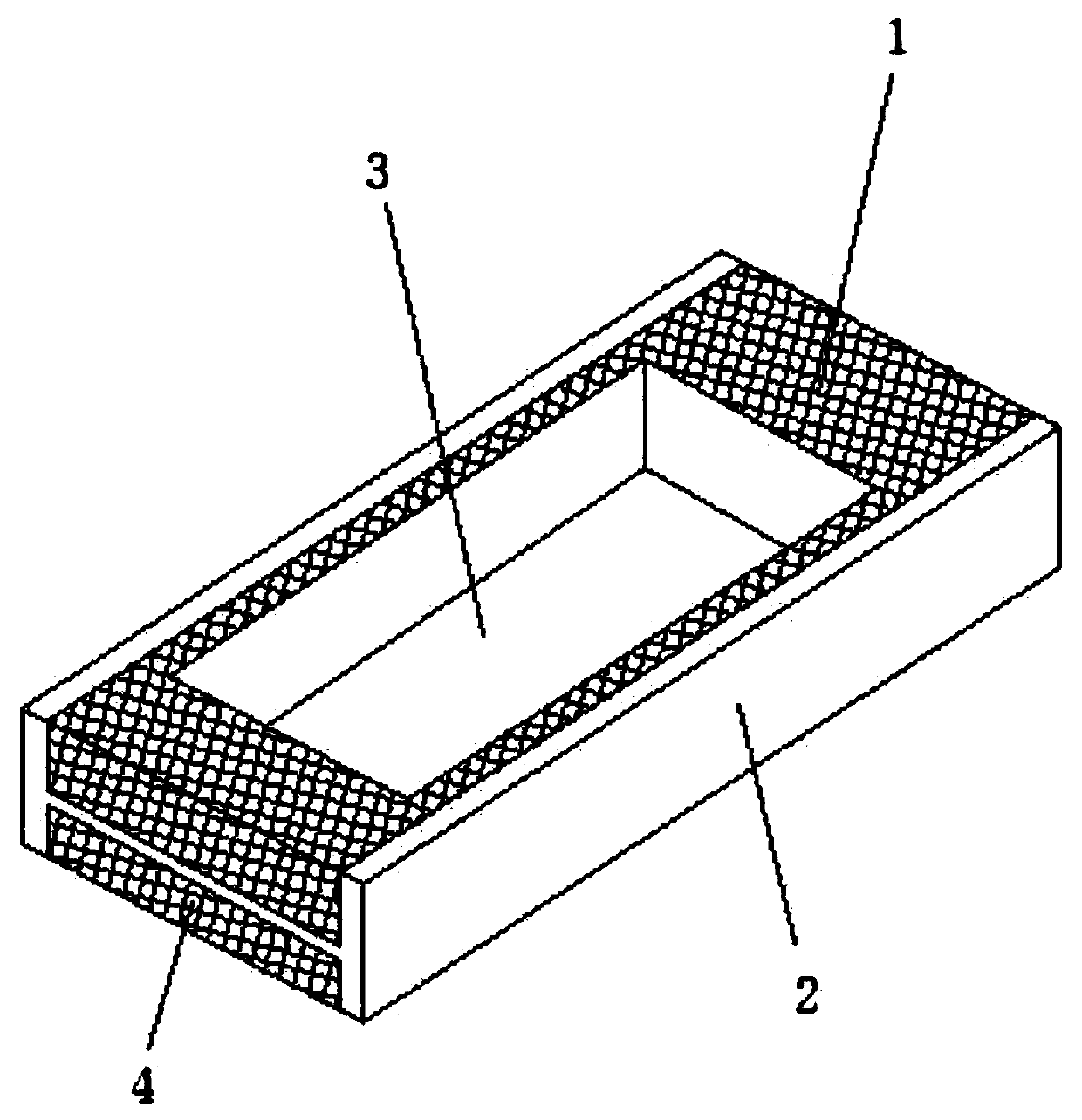

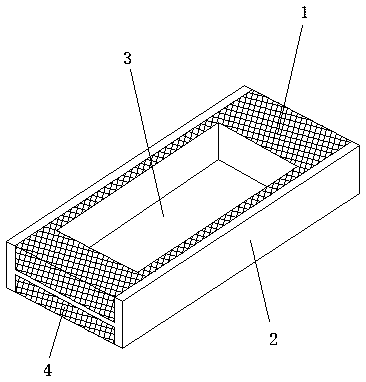

Shock-proof and break-proof packaging box

InactiveCN109606894AHigh strengthSolve the problem of high plasticity and low strengthContainers to prevent mechanical damageRigid containersHigh intensityEngineering

The invention relates to a shock-proof and break-proof packaging box, and belongs to the technical field of packaging. The shock-proof and break-proof packaging box is composed of upper layer foam, aplastic frame and lower layer foam. The plastic frame has a flat H-shaped cross section, the upper layer foam is connected and fixed to the upper part of the plastic frame, and the lower layer foam isconnected and fixed to the lower part of the plastic frame. A storage groove is formed in the middle part of the upper layer foam. The shock-proof and break-proof packaging box has a novel structure,a clear preparation principle and a simple method, and an integrated structure is constituted by the plastic frame, the upper layer foam and the lower layer foam. Compared with a conventional foam packaging box, the shock-proof and break-proof packaging box solves the problems of low plasticity and low strength of the conventional foam box, the strength of the foam is increased, the anti-pressurecapability of the shock-proof and break-proof packaging box is improved, and the transportation demands of the shock-proof and break-proof packaging box are further met.

Owner:嘉兴市竹林塑料泡沫有限公司

Anti-breaking foam packaging box and manufacturing method thereof

InactiveCN107777038AHigh strengthSolve the problem of high plasticity and low strengthRigid containersAlloyUltimate tensile strength

The invention discloses an anti-breaking foam packaging box and a manufacturing method thereof and belongs to the technical field of packaging. The anti-breaking foam packaging box comprises an upperfoam layer, an alloy frame and a lower foam layer, wherein the alloy frame has the section of a flat H-shaped structure, the upper foam layer is connected and fixed above the alloy frame, the lower foam layer is connected and fixed below the alloy frame, and a storage groove is formed in the middle of the upper foam layer. The anti-breaking foam packaging box is novel in structure, the preparationprinciple is clear, and the method is simple; compared with conventional foam packaging boxes, the anti-breaking foam packaging box adopting the integrated structure formed by the alloy frame, the upper foam layer and the lower foam layer overcomes the defects of high plasticity and low strength of conventional foam plastic, the strength of foam is enhanced, the pressure resistance of a product is improved, and transportation demands of products are further met.

Owner:句容市武杭传动机械制造有限公司

Ultraviolet light coating and preparation method thereof

InactiveCN107556903AFast curing rateIncrease the degree of cross-linkingPolyurea/polyurethane coatingsUltraviolet lightsMechanical property

The invention relates to an ultraviolet light coating and a preparation method thereof and belongs to the technical field of preparation of engineering materials. The coating is prepared from the following raw materials in percentages by weight: 40-50% of polyurethane acrylate, 15-20% of unsaturated esters, 3-6% of a photoinitiator, 1-3% of a flatting agent, 2-8% of an organic pigment and the balance of water. The preparation principle is clear and the processing method is simple. The ultraviolet light coating provided by the invention is high in curing speed and great in degree of crosslinking, and the flexibility and rigidity of polyurethane are balanced. By adding the polyurethane acrylate into the ultraviolet light coating, the viscosity of a system can be reduced and the curing rate of the system can be improved, so that the ultraviolet light coating has good constructability and excellent mechanical properties, the dosage of a diluting monomer and an organic solvent can be reduced, the ultraviolet light coating reaches certain surface hardness, the wear resistance of the coating can be improved, and the service performance is further improved.

Owner:江苏晶王新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com