Method for preparing AlCrTiN/WC-12Co composite coating on surface of hot-work die steel

A technology of hot work die steel and composite coating, applied in the treatment of cathode ion plating and supersonic flame spraying on the surface of hot work die steel, and in the field of preparing AlCrTiN/WC-12Co composite coating on the surface of hot work die steel, which can solve the problem of Can not meet the actual production needs, cathodic ion plating coating wear and failure and other problems, to achieve the effect of improving hardness, scientific method, and clear preparation principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below through the technical scheme, drawings and embodiments of the present invention.

[0023] (1) Place the sample of the hot work die steel matrix in an ethanol solution and ultrasonically clean it for 20 minutes to remove oil and impurities on the matrix, and then use 40-mesh corundum to roughen the surface of the matrix by sandblasting.

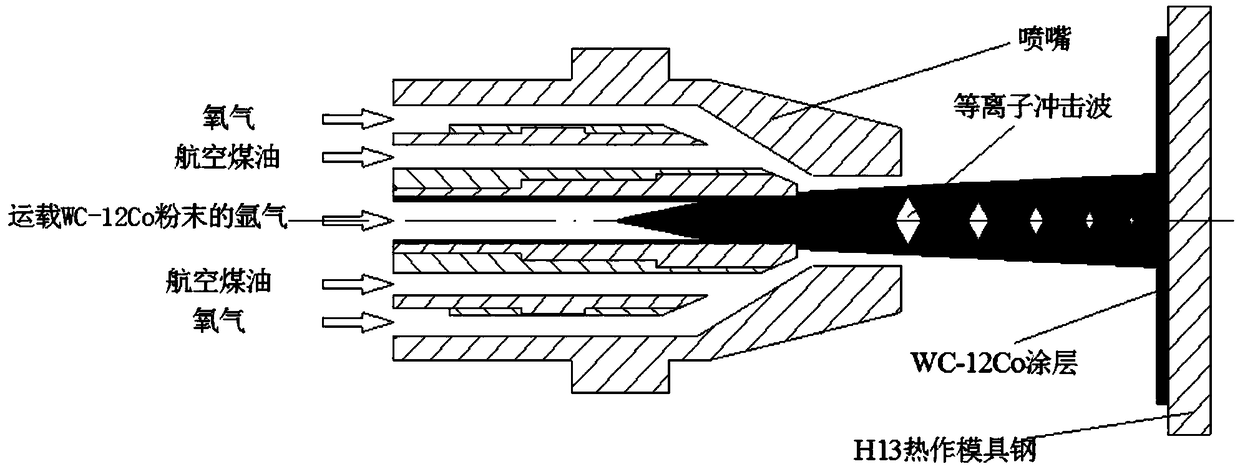

[0024] (2) When spraying WC-12Co coating, aviation kerosene is used as fuel, oxygen is used as combustion-supporting gas, and nitrogen is used as powder feeding gas. The oil pressure is 1.25MPa, the oxygen pressure is 1.58MPa, the water temperature is controlled at 35°C, and the spraying pressure is 0.95MPa, such as figure 1 shown.

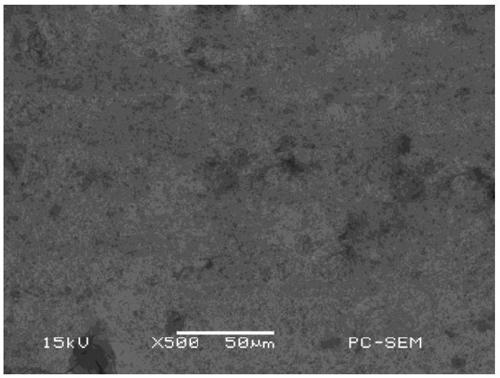

[0025] (3) The surface structure of the prepared WC-12Co coating is dense and the porosity is low, such as image 3 shown. The coating is tightly combined with the substrate without peeling off and cracks, such as Figure 4 shown.

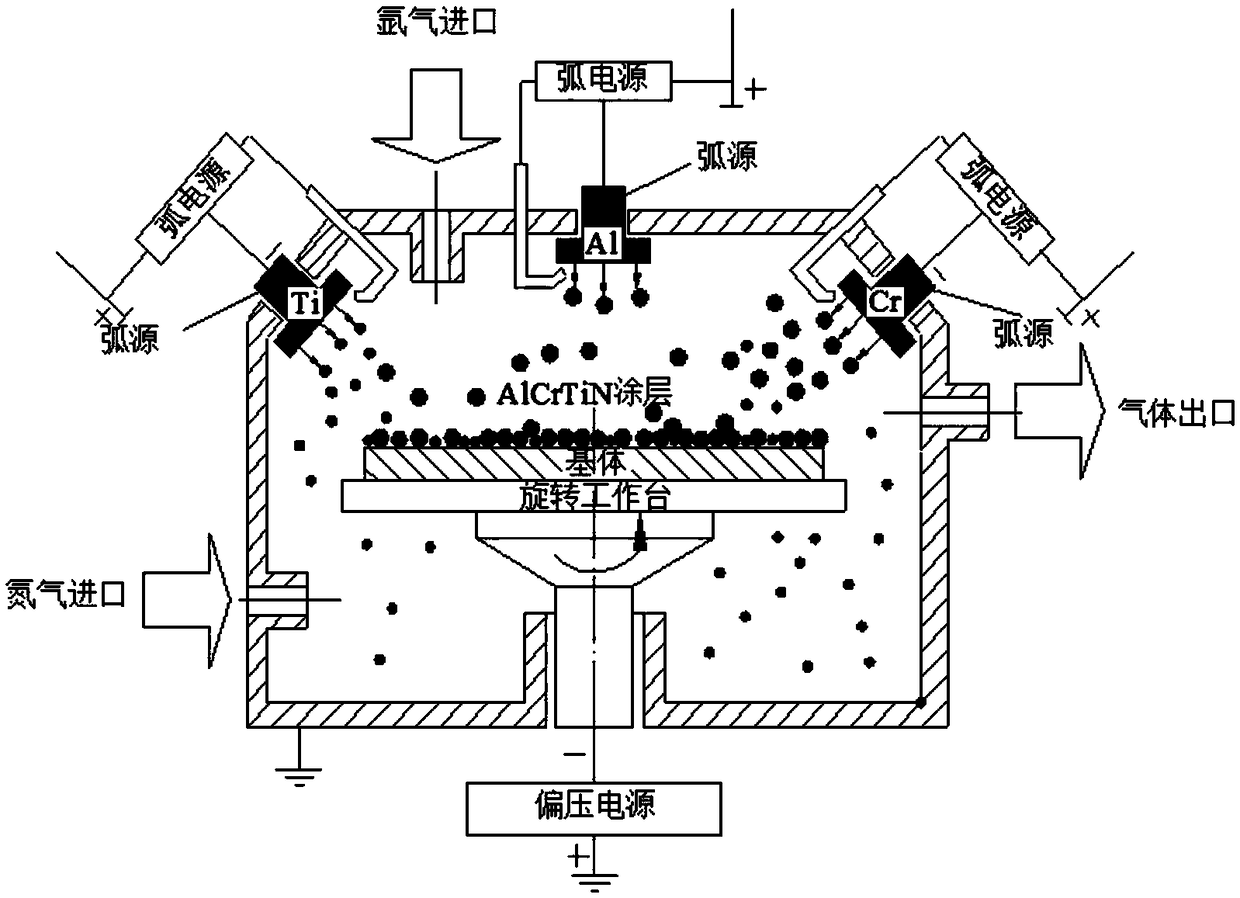

[0026] (4) The W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com