An OLED with a micrometer periodic structure ITO electrode and a preparation method thereof

A periodic structure and electrode technology, applied in circuits, electrical components, electric solid state devices, etc., can solve the problems of difficult process technology route, low luminous efficiency, short circuit, etc., to improve the injection efficiency, increase the light output efficiency, and the process foundation is mature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

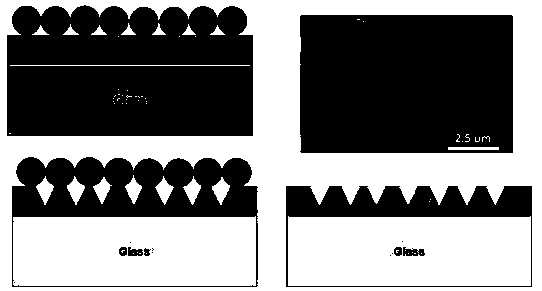

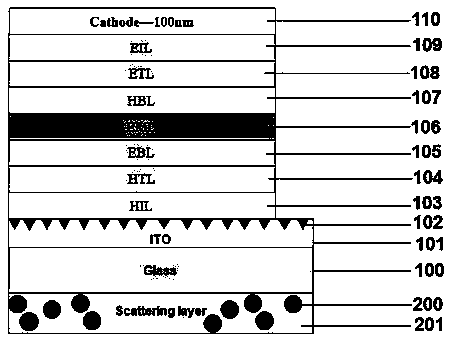

[0021] Such as Figure 1-2 As shown, a kind of OLED with micron periodic structure ITO electrode comprises glass substrate 100; Barrier layer 105, light emitting layer 106, hole blocking layer 107, electron transport layer 108, electron injection layer 109 and metal electrode layer 110; the back of the glass substrate 100 is provided with a scattering layer 200 and a curing layer 201 in sequence.

[0022] Such as Figure 1-2 As shown, a kind of OLED with micron periodic structure ITO electrode, the thickness of ITO layer 101 is 150~300nm; 107. The thickness of the electron transport layer 108, electron injection layer 109, and metal electrode layer 110 is 10-500 nm; the light-emitting layer is one of monochromatic light R, G, B or monochromatic light R, G, B The light-emitting layer composed of a combination; the metal electrode layer 110 is a combination of Al layer or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com