Preparation method of nano carbon based loaded two-dimensional noble metal cluster composite material

A technology of composite materials and noble metal ions, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc. Large-scale batch preparation of graphene composite materials, cumbersome preparation of graphite oxide, etc., to achieve the effect of enhancing synergy, strong application value, and enriching preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

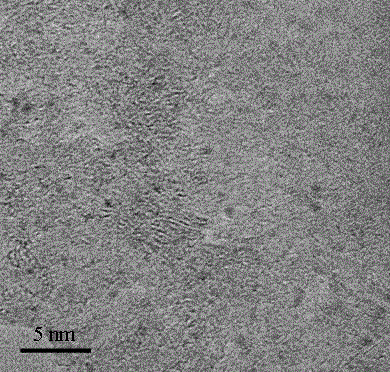

Image

Examples

Embodiment 1

[0021] The first step is the preparation of oxidized carbon black. 50mg of nano-carbon black (Vulcan, XC-72) was soaked in a mixed solution of 1M sulfuric acid and saturated ammonium persulfate for 24 hours at room temperature, and the oxidized carbon black particles were taken out, and washed 3 times with distilled water to remove sulfuric acid on the surface of carbon black Salt and other sundries should be dried in an oven at 50°C for 12 hours, and stored in a desiccator.

[0022] In the second step, put 50mg of oxidized carbon black into 50ml of distilled water, ultrasonically disperse for 30 minutes, take the dispersed oxidized carbon black suspension and drop it on the glass carbon electrode, let it dry naturally and slowly.

[0023] In the third step, immerse the glass electrode in a lead nitrate solution with a concentration of 2mM, and adjust its pH value to 11 with a 1M NaOH solution, and the immersion reaction time is 2h.

[0024] The fourth step is to take out the...

Embodiment 2

[0027] The first and second steps of this implementation are the same as in Embodiment 1.

[0028] The third step is to immerse the glass electrode in 2mM lead nitrate solution and adjust its pH value to 12 with 1M NaOH solution for 4 hours.

[0029] The fourth step is to take out the glass carbon electrode and insert 0.1M NaClO 4 solution, in N 2 In the atmosphere, the electrochemical reduction was carried out at the potential of –1V for 5min. (The reference electrode is Ag / AgCl, 3MCl ? electrode).

[0030] In the fifth step, after reduction, the glassy carbon electrode was placed in N 2 Immerse in 0.5mM K under gas protection 2 PtCl 4 and 0.5mM RuCl 3 In the mixed solution, react for 10 minutes, take out the glass carbon electrode and wash it with distilled water. Its methanol oxidation reaction is about 14 times the catalytic activity of commercial E-TEKPtRu / C (carbon black-based). (Catalytic activity test conditions: the reference electrode is Ag / AgCl, 3MCl ? Ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com