Gradient-sized pore sintered core vapor chamber heat exchanger for electronic chip heat dissipation and preparation method of vapor chamber heat exchanger

A technology of electronic chips and vapor chambers, which is applied in the manufacture of electric solid devices, semiconductor/solid state devices, circuits, etc., can solve the problems of lowering the start-up operating temperature, which is not conducive to vapor chambers, etc., and achieves enlarged contact area and enhanced boiling and condensing heat capacity, the effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

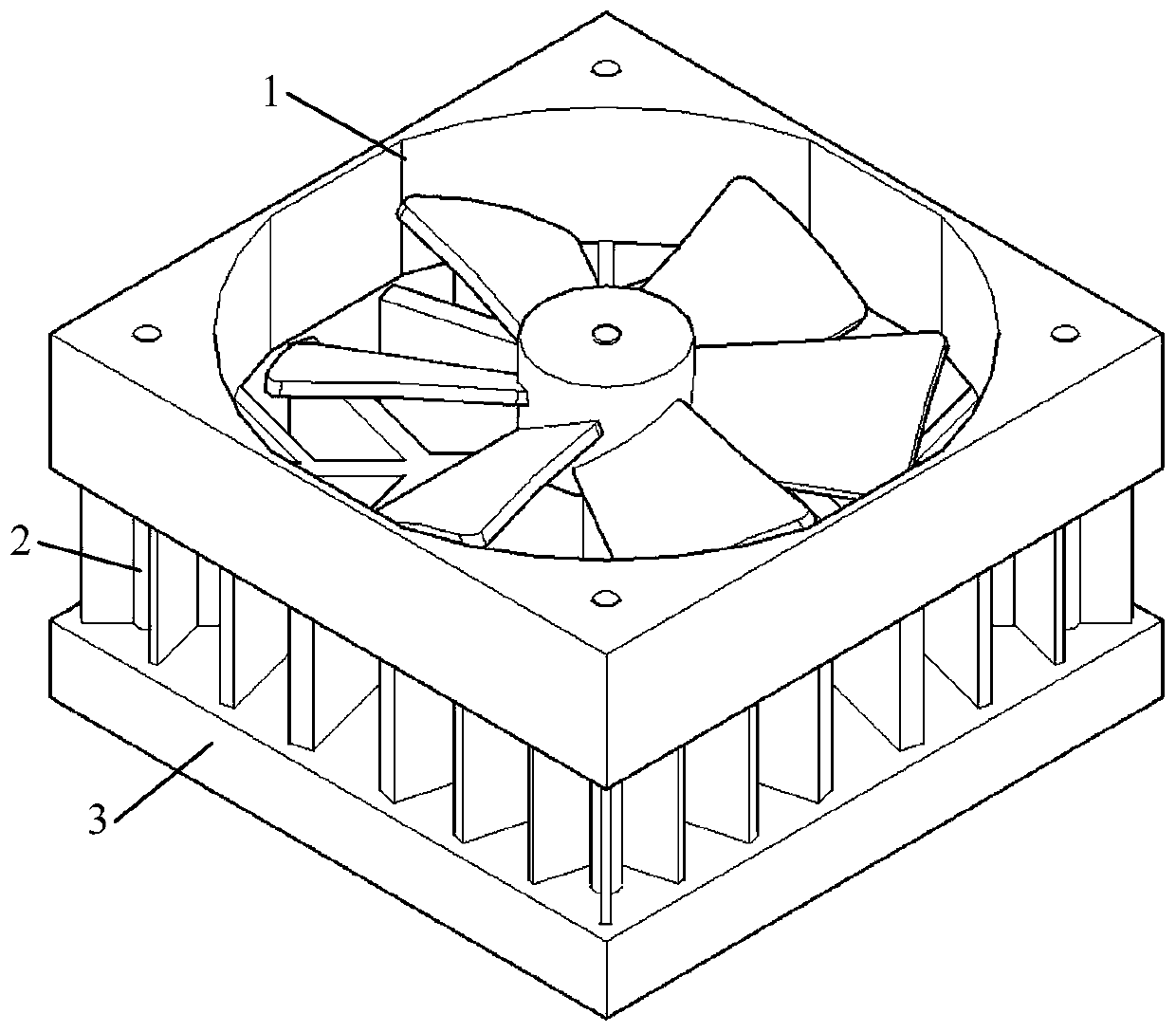

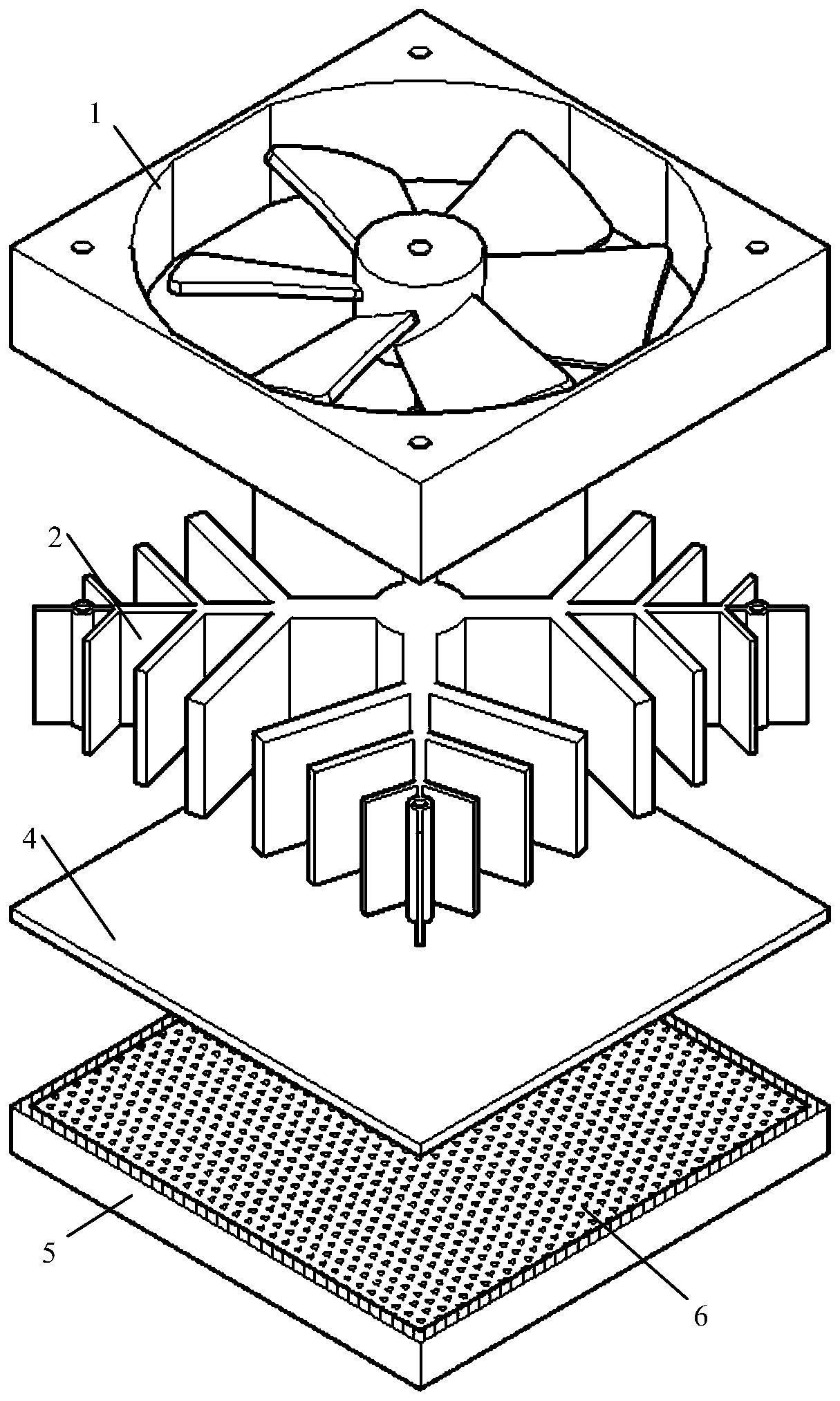

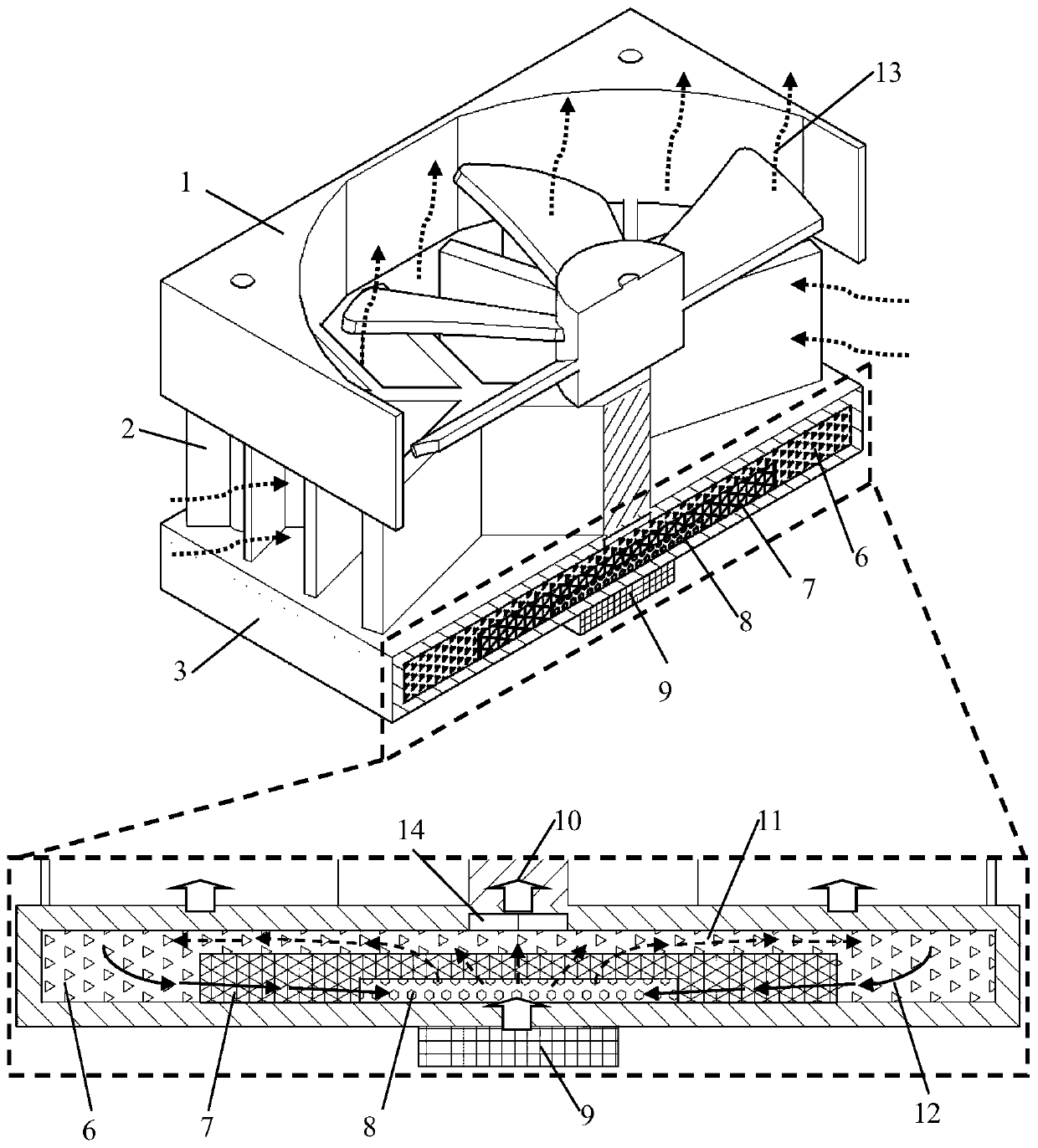

[0031] Such as figure 1 As shown, the gradient-scale porous sintered-core soaker plate heat exchanger suitable for heat dissipation of electronic chips involved in the present invention is composed of a cooling fan 1, veined heat-dissipating fins 2 and a sintered-core soaker plate 3, as figure 1 and figure 2shown. In order to reduce the weight of the heat exchanger, the vapor chamber shell and vein-shaped cooling fins are processed according to the actual situation, and can be processed by aluminum alloy or other metal materials such as copper. Sintered core with gradient scale pores inside the vapor chamber. The vapor chamber is filled and packaged with a liquid working medium that can change phase after being heated, such as acetone, alcohol, ammonia water, refrigerant, electronic fluorinated liquid, etc. In order to ensure the excellent heat transfer performance o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com