A flip-chip algainp red light micro-led and its preparation method

A flip-chip, red light technology, used in semiconductor devices, electrical components, circuits, etc., can solve problems such as limiting the light extraction performance of red LEDs and small energy gap, and achieve improved bonding yield, easy access, and clear preparation principles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

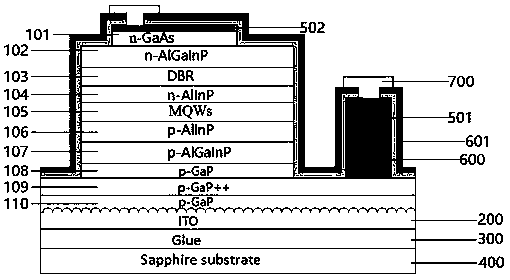

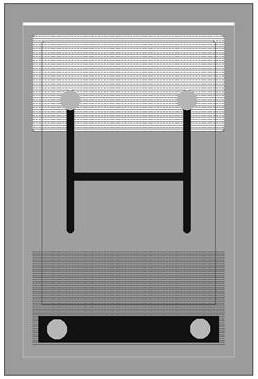

[0028] Such as Figure 1-2As shown, a fabrication method of AlGaInP red light Micro-LED with flip-chip structure, AlGaInP LED epitaxial layer grows corrosion stop layer, n-GaAs ohmic contact layer sequentially on n-type GaAs substrate by metal-organic chemical vapor deposition (MOCVD) 101, n-AlGaInP expansion layer 102, DBR layer 103, n-AlInP confinement layer 104, light emitting layer 105, p-AlInP confinement layer 106, p-AlGaInP expansion layer 107, p-GaP current spreading layer 108, p-GaP ohmic Contact layer 109, p-GaP roughened bonding layer 110, use acid system roughening solution to roughen p-GaP roughened bonding layer 110, deposit ITO layer 200 by electron beam evaporation on the surface after roughening, on the ITO layer Spin-coat a layer of UV-curable optical adhesive (NOA73) on the surface at a high speed, and use UV curing for 5-500 minutes after coating to for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com