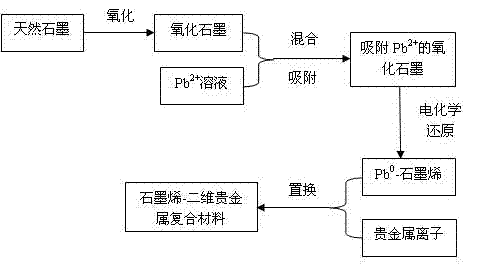

Method for manufacturing graphene-two-dimensional precious metal atomic layer composite materials

A technology of composite materials and noble metal ions, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of insufficient performance improvement of composite materials, and achieve Enhanced synergistic effect, convenient operation, and large particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

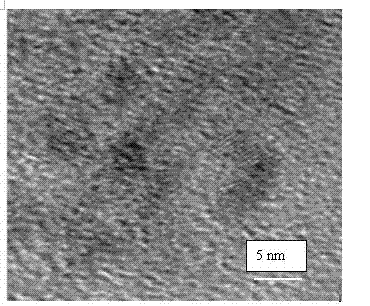

Image

Examples

Embodiment 1

[0022] The first step is the preparation of graphite oxide. Add 10g of natural graphite (50~80μm in particle size) to 230ml of concentrated sulfuric acid containing 5g of sodium nitrate (in an ice bath), then add 30g of KMnO 4 , and control the solution below 20°C, stir evenly, put it in a 35°C water bath for 30 minutes, then slowly add 460ml of distilled water to keep the reaction temperature at 98°C, and then react for 15 minutes, add 1.4L of distilled water and 10ml of hydrogen peroxide, The yellow suspension in the solution was centrifuged until the filtrate was washed with BaCl 2 No sulfate ion was detected, and the product was dried in air at 60°C for 12 hours, and stored in a desiccator.

[0023] In the second step, add 20mg of graphite oxide to 20ml of distilled water, ultrasonically disperse for 30min, take the dispersed graphite oxide solution and drop it on the glass carbon electrode, let it dry naturally and slowly.

[0024] In the third step, immerse the glass c...

Embodiment 2

[0028] The first, second, third, and fourth steps of this implementation are the same as in Embodiment 1.

[0029] The fifth step, after reduction, immerse the glass carbon electrode in 1mM K 2 PtCl 4 solution, reacted for 8 minutes, took out the electrode and washed it with distilled water. The catalytic activity of the composite for methanol oxidation reaction is ~10 times higher than that of commercial E-TEK Pt / C. (Catalytic activity test conditions: the reference electrode is Ag / AgCl, 3M Cl- electrode, the voltage scanning rate is 25mV / s, the solution is 0.5MCH 3 OH+0.1MHClO 4 , at a voltage of 0.58 V, the peak value of the graphene material of the present invention is 7.3 mA / μg, and the peak value of the commercial E-TEK Pt / C is 0.74 mA / μg).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com