Novel foaming agent

A foam agent, a new type of technology, applied in the direction of aerosol delivery, skin care preparations, medical preparations of non-active ingredients, etc., can solve the problem that the foam agent is difficult to meet low temperature storage or use, so as to improve the rapid elimination ability, Enhanced stability, use of reduced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

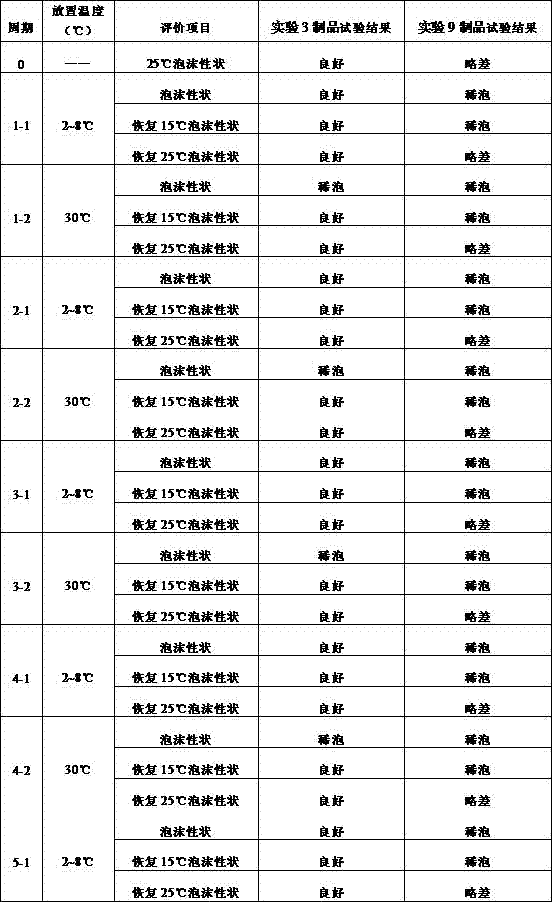

Image

Examples

Embodiment 1

[0033] components Dosage % (w / w) Betamethasone valerate 0.12 ethanol 57.79 Propylene Glycol 2.00 cetyl alcohol 1.10 stearyl alcohol 0.50 Tween 60 0.025 Anhydrous citric acid 0.073 potassium citrate 0.027 water 33.69 propane / butane 4.675

[0034] Mix ethanol and propylene glycol. Add betamethasone valerate, cetyl alcohol, and stearyl alcohol, and stir until dissolved and clarified to form an alcohol phase. Dissolve Tween 60, citric acid, and potassium citrate in water, stir until dissolved and clear, pour into the same container, and filter to obtain the content. Fill the content into a pressure-resistant aluminum bottle, fill with propane and butane mixed propellant, and complete the preparation.

Embodiment 2

[0036] %(w / w) 1 2 3 4 5 6 7 8 9 Clobetasol Propionate 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05 Absolute ethanol 50.1 48.39 50.1 53.1 56.1 49.1 56.1 56.1 50.1 glycerin 3 3 3 3 3 13 3 3 3 cetyl alcohol 0.9 0.9 0.9 0.9 0.9 0.9 0.9 0.9 0.9 stearyl alcohol 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 0.4 Tween 60 0 0.01 0.01 0.02 0.02 0.02 0.05 1 1 citric acid 0.07 0.07 0.07 0.07 0.07 0.07 0.07 0.07 0.07 potassium citrate 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 0.03 water 40.44 42.15 40.44 37.43 34.43 31.43 34.4 33.45 39.45 Tetrafluoroethane 5 5 5 5 5 5 5 5 5

[0037] organic phase preparation

[0038] Heat ethanol to about 50°C, add glycerin, cetyl alcohol, stearyl alcohol, Tween 60, stir to dissolve and clarify. Add the clobetasol propionate and stir to make the solution clear.

[0039] Aqueous phase preparation

[0040] Dissol...

Embodiment 3

[0051] components Dosage % (w / w) Terbinafine Hydrochloride 1 Ethanol (96%) 54 Propylene Glycol 6 cetyl alcohol 1.1 stearyl alcohol 0.4 Polyoxyethylene 40 stearate 0.02 citric acid 0.06 potassium citrate 0.04 water 29.38 Tetrafluoroethane 8

[0052] Mix ethanol and propylene glycol and heat to about 50°C. Add terbinafine hydrochloride, cetyl alcohol, and stearyl alcohol, stir until dissolved and clear, filter, and pour the filtrate into a pressure-resistant metal tank. Dissolve polyoxyethylene 40 stearate, citric acid, and potassium citrate in water, stir until dissolved and clear, filter, pour the filtrate into the same container, and mix it automatically to obtain the content. The content is filled in a pressure-resistant aluminum bottle, filled with tetrafluoroethane, and the preparation is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com