Asenapine microsphere agent and preparation method thereof

A technology of microspheres and preparations, which is applied in the field of asenapine microsphere preparations and its preparation, can solve the problems of only 60% of the maximum effective drug utilization rate, high drug loss, poor transdermal properties of asenapine, etc., and achieve excellent Sustained release performance, high production efficiency, and low burst release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

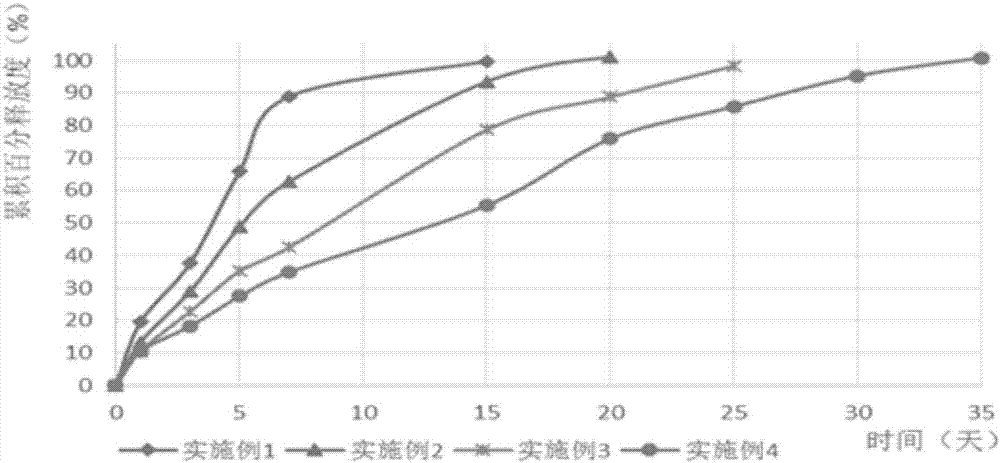

Embodiment 1

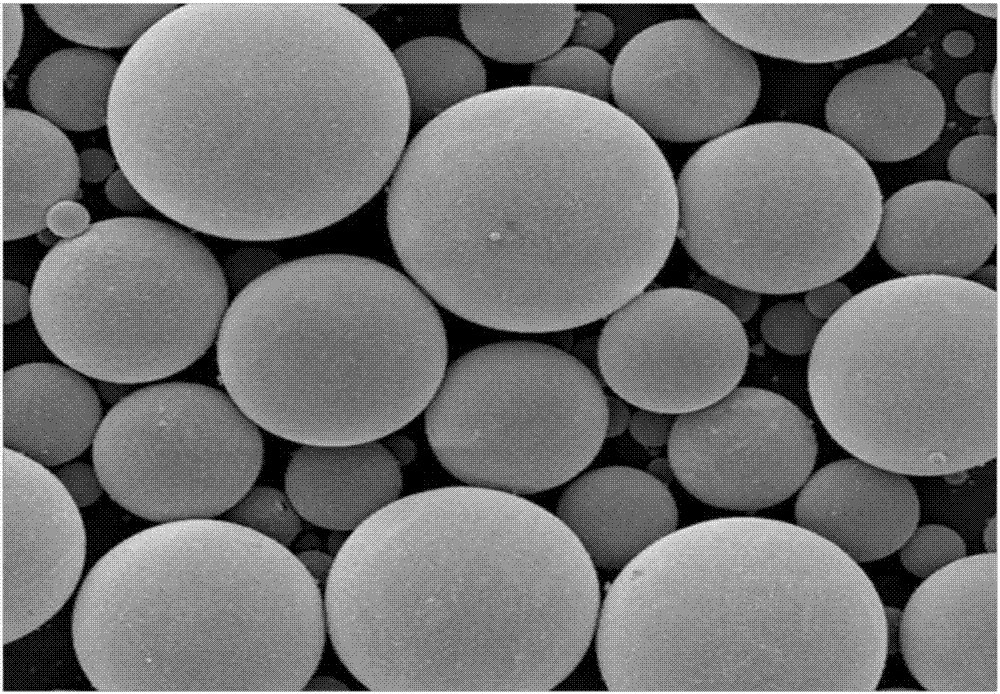

[0051] Preparation of asenapine microspheres sustained release for 1 week

[0052] Table 1 Embodiment 1 prescription composition

[0053] Raw materials prescription one Asenapine Maleate 2.25g (calculated as Asenapine) PLGA (about 20000) 7.00g (Model 5050) Dichloromethane 120ml

[0054] Preparation

[0055] Take respectively asenapine maleate and PLGA (model is 5050, molecular weight is 20000) of recipe quantity, measure the dichloromethane of prescription quantity, PLGA is dissolved in dichloromethane, then asenapine maleate Gently add into the dichloromethane solution dissolved in PLGA, stir while adding, keep stirring and shearing for 10-15 minutes, ultrasonic for 1-2 minutes, to obtain a homogeneous oil phase. Spray-dry the homogeneous oil phase under stirring, adjust the spray atomization device, control the size of the sprayed droplets, control the drying temperature at 35-40°C, and control the particle size D50 of the prepared micro...

Embodiment 2

[0057] Preparation of Asenapine Microspheres Sustained Release for 2 Weeks

[0058] Table 2 embodiment 2 prescription composition

[0059] Raw materials Prescription two Asenapine Maleate 2.25g (calculated as Asenapine) PLGA (about 55000) 7.50g (Model 5050) Dichloromethane 125ml

[0060] Preparation:

[0061] Take respectively asenapine maleate and PLGA (model is 5050, molecular weight is 55000) of recipe quantity, measure the dichloromethane of recipe quantity, PLGA is dissolved in dichloromethane, then asenapine maleate Gently add into the dichloromethane solution dissolved in PLGA, stir while adding, keep stirring and shearing for 10-15 minutes, ultrasonic for 1-2 minutes, to obtain a homogeneous oil phase. Spray-dry the homogeneous oil phase under stirring, adjust the spray atomization device, control the size of the sprayed droplets, and control the drying temperature at 35-40°C, and control the particle size D50 of the prepared micro...

Embodiment 3

[0063] Preparation of Asenapine Microspheres Sustained Release for 3 Weeks

[0064] Table 3 Embodiment 3 prescription composition

[0065] Raw materials Prescription Three Asenapine Maleate 2.25g (calculated as Asenapine) PLGA (about 25000) 3.50g (model 5050) PLGA (about 55000) 4.50g (Model 7525) Dichloromethane 130ml

[0066] Preparation:

[0067] Take respectively the asenapine maleate of prescription quantity, the PLGA of different models and molecular weight (model is respectively 5050 and 7525; Molecular weight is 25000 and 55000 respectively), measures the dichloromethane of prescription quantity, PLGA is dissolved in two Add maleic acid asenanate slowly to the PLGA-dissolved dichloromethane solution in chloromethane, stir while adding, keep stirring and shearing for 10-15 minutes, and ultrasonic for 1-2 minutes to obtain a homogeneous oil phase. Spray-dry the homogeneous oil phase under stirring, adjust the spray atomization ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com