High-viscoelasticity Pickering emulsion and preparing method and application thereof

An emulsion and high-viscosity technology, applied in the field of Pickering emulsions, can solve the problems of pure silica particles with strong hydrophilicity, inability to exhibit pH response, unfavorable stabilization of Pickering emulsions, etc. The effect of high elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

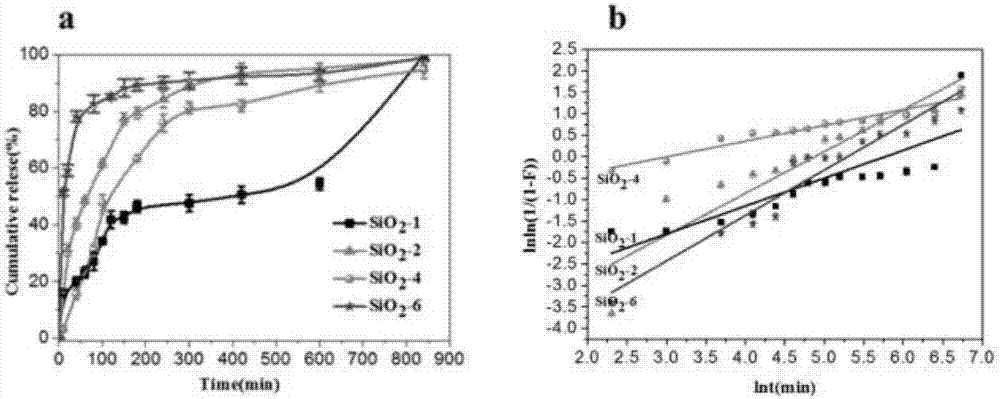

Examples

Embodiment Construction

[0028] The present invention will be further described below in combination with specific embodiments, so as to better understand the present invention.

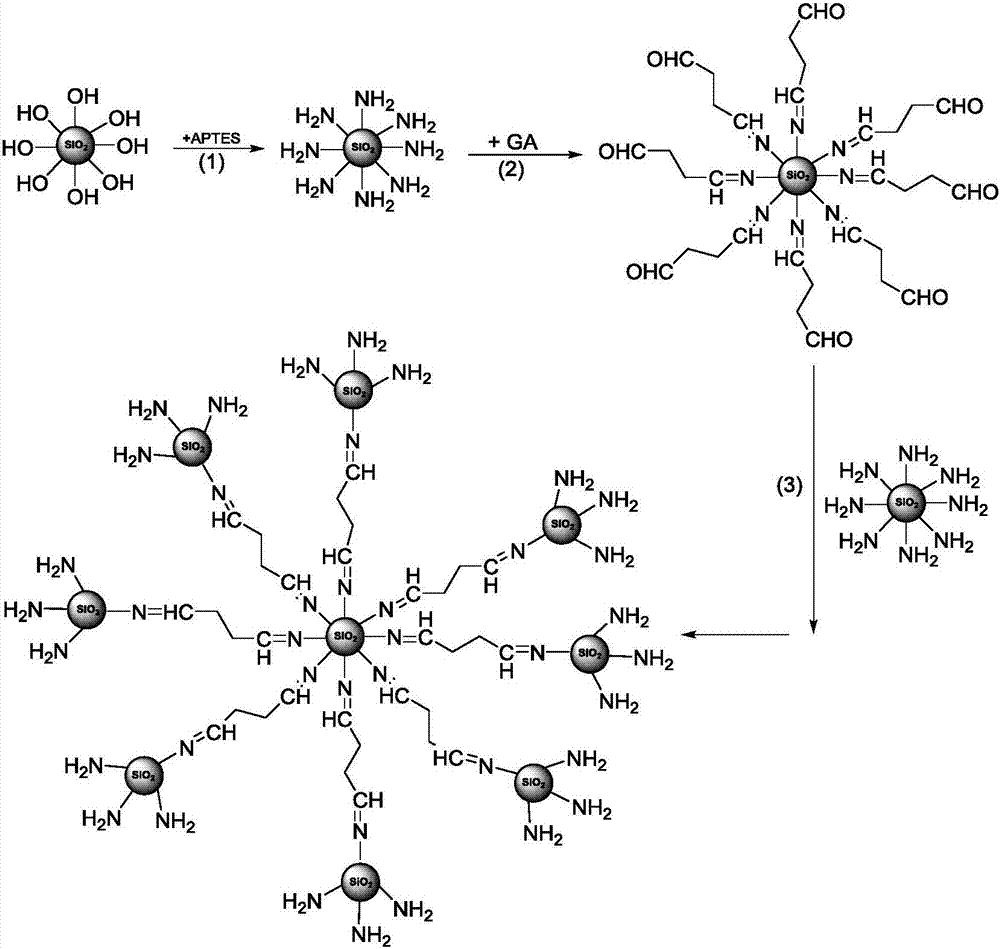

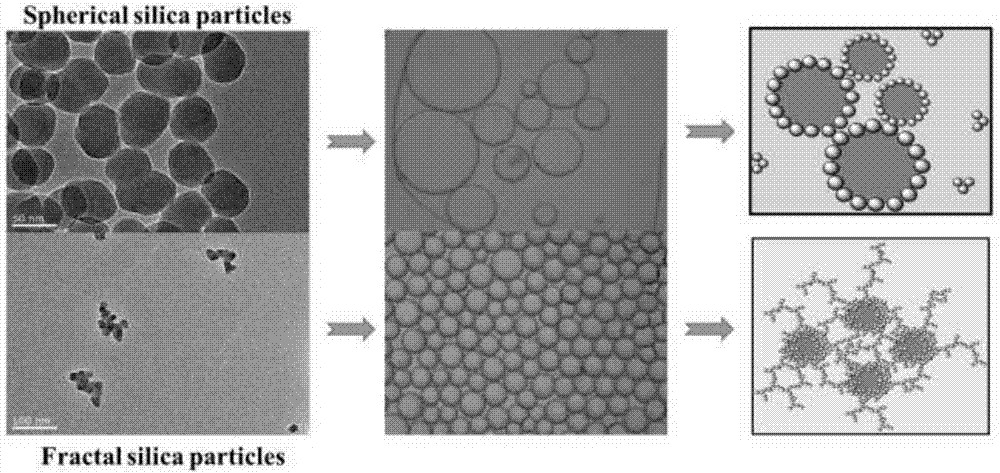

[0029] 1. Fractal SiO2 2 Synthesis

[0030] First prepare amino-terminated silica (SiO 2 -NH 2 ) particles (Guan et al., 2009). The steps are as follows: add 1.0 g of hydrophilic silica and 10 mL of APTS to 50 mL of ethanol / water (v / v=3:1) at pH=3.6, and then reflux at 80° C. for 12 h. After the mixture was centrifuged, washed three times with ethanol and water respectively, and freeze-dried to obtain amino-terminated silica particles (SiO 2 -NH 2 ). Then prepare aldehyde-terminated silica particles (SiO 2 -CHO) (Shi et al., 2009), the steps are as follows: after dispersing 0.5 g of the above particles in 30 mL (pH=8) phosphate buffer solution, add 50 mL of 25% GA. The reaction was stirred at room temperature for 12h. After the mixture was centrifuged, washed three times with ethanol and water respectively, and free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com