Multi-stimuli responsive shell crosslinked polymeric micelle and preparation method thereof

A cross-linked polymer and multiple stimulation technology, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, emulsion delivery, etc., to achieve the effect of expanding the application range, uniform size, and simple and convenient release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

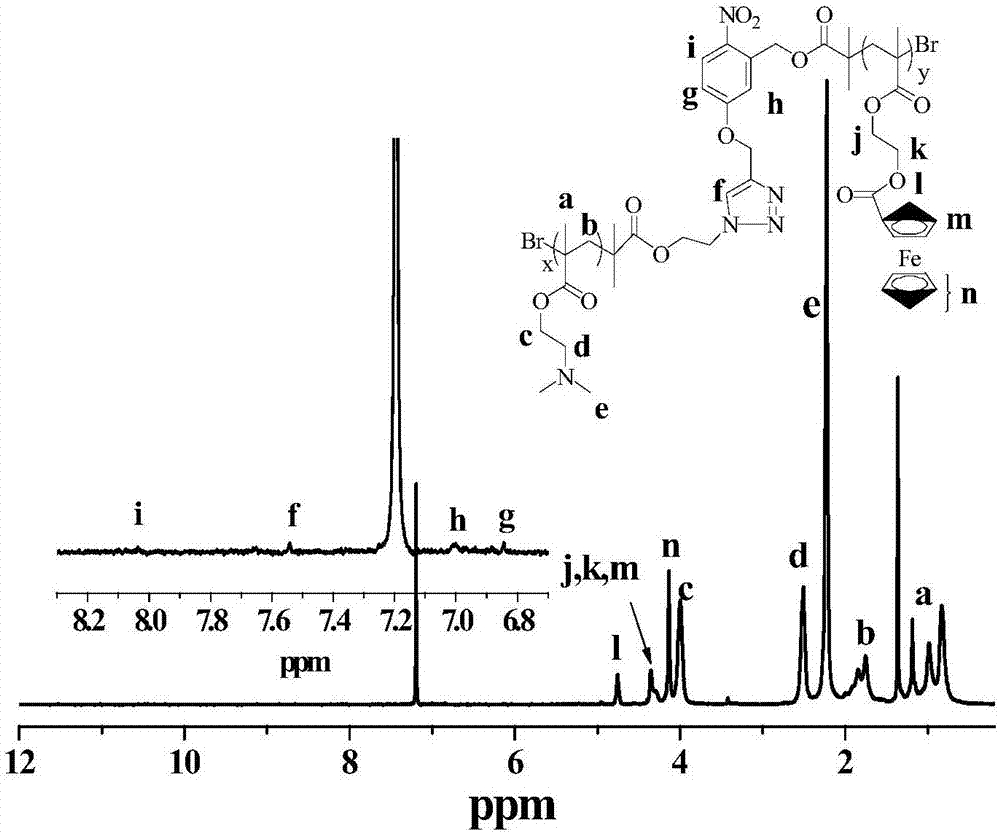

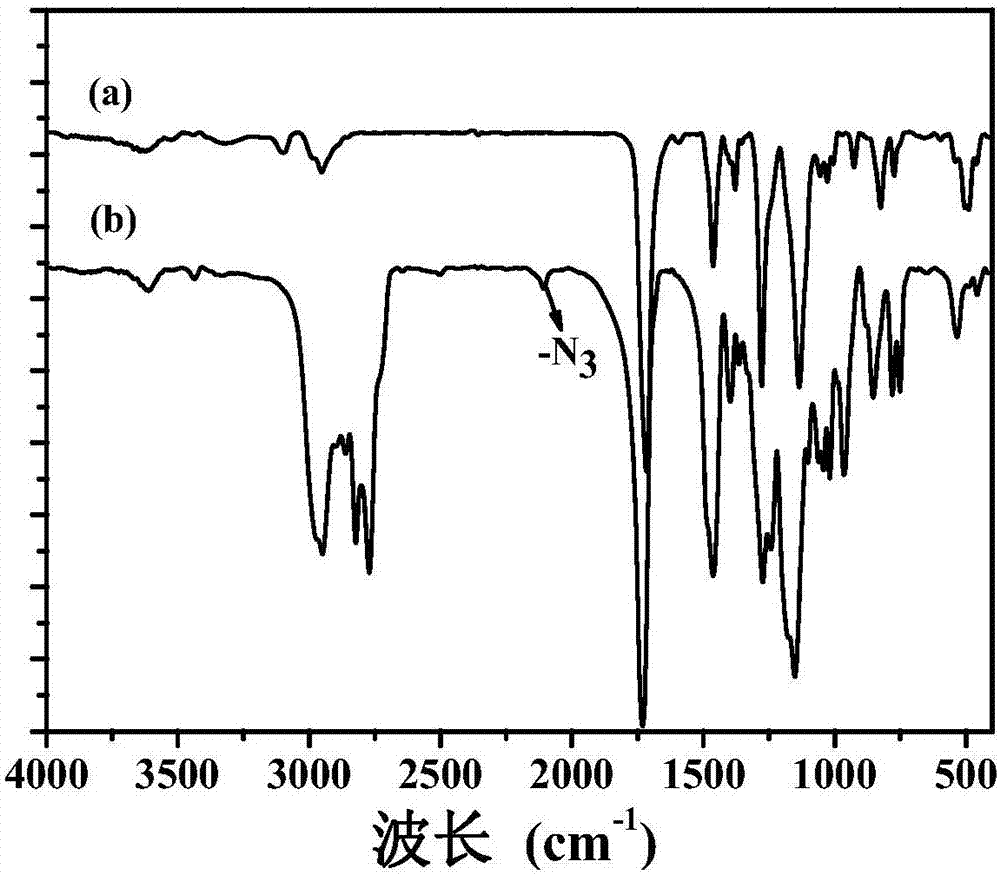

[0046]

[0047]

[0048] 1. Dissolve azide-Br (0.047g, 0.2mmol), DMAEMA (3.36ml, 20mmol), PMDETA (0.035g, 0.2mmol) in 4mL DMF, add CuBr (0.029g, 0.2 mmol), followed by continuous freeze-thaw degassing once, and then reacted at 60°C for 4 hours under a nitrogen atmosphere. Precipitate in diethyl ether to obtain a white solid, namely the polymer of formula I-1.

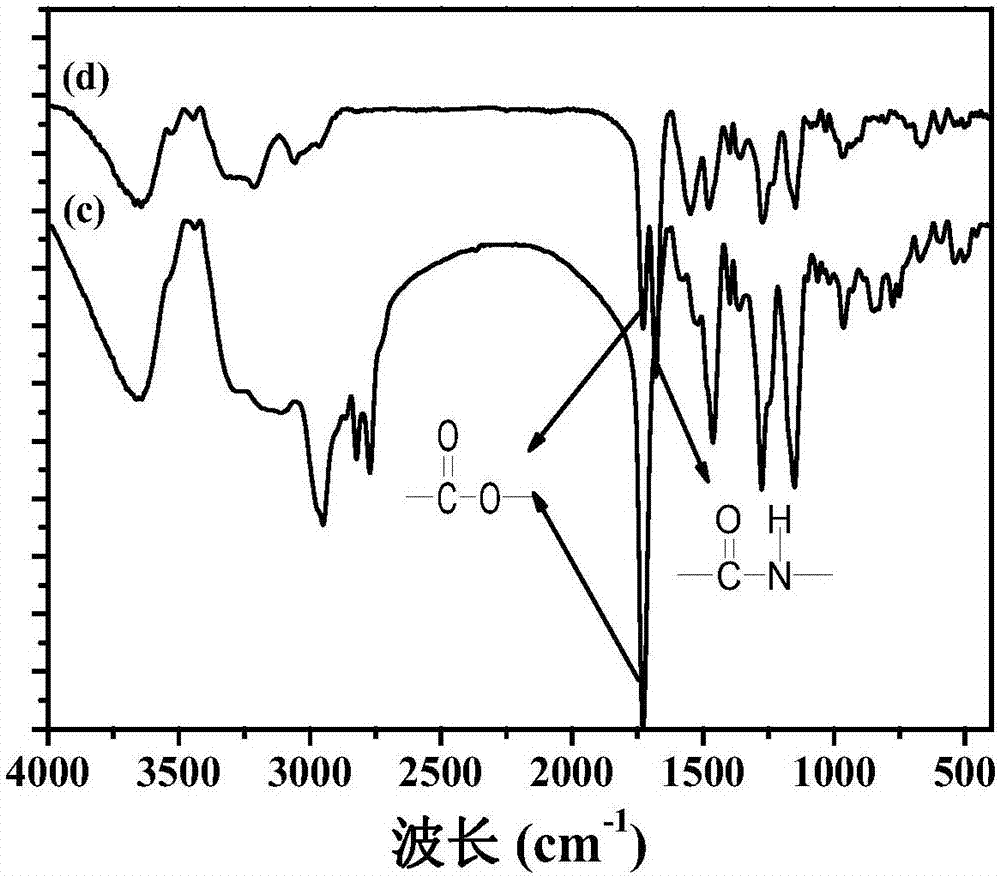

[0049] 2. Dissolve alkyne-ONB-Br (0.0285g, 0.08mmol), MAEFC (1.098g, 3.2mmol), PMDETA (0.0138g, 0.08mmol) in 4mL DMF, add CuBr ( 0.012g, 0.08mmol), followed by continuous freeze-thaw degassing once, and then reacted under nitrogen atmosphere at 90°C for 6 hours. Precipitate in excess n-hexane to obtain a yellow solid, namely the polymer of formula II-1.

[0050] 3. Dissolve the polymer of formula I-1 (2.76g, 0.11mmol), polymer II-1 of formula II-1 (0.76g, 0.1mmol), PMDETA (0.035g, 0.2mmol) in 6mL of DMF, and continuously freeze-thaw and degas Add CuBr (0.029g, 0.2mmol) after 2 times, then freeze-thaw and degas ...

Embodiment 2

[0054]

[0055]

[0056] 1. Dissolve azide-Br (0.094g, 0.4mmol), DMAEMA (5.36ml, 32mmol), PMDETA (0.071g, 0.4mmol) in 6mL DMF, add CuBr (0.058g, 0.4 mmol), followed by continuous freeze-thaw degassing once, and then reacted at 60°C for 4 hours under a nitrogen atmosphere. Precipitate in diethyl ether to obtain a white solid, namely the polymer of formula I-2.

[0057] 2. Dissolve alkyne-ONB-Br (0.0285g, 0.08mmol), MAEFC (1.647g, 4.8mmol), PMDETA (0.0138g, 0.08mmol) in 4mL DMF, add CuBr ( 0.012g, 0.08mmol), followed by continuous freeze-thaw degassing once, and then reacted under nitrogen atmosphere at 90°C for 6 hours. Precipitate in excess n-hexane to obtain a yellow solid, namely the polymer of formula II-2.

[0058] 3. Dissolve the polymer of formula I-2 (1.58g, 0.11mmol), the polymer of formula II-2 (1.04g, 0.1mmol), PMDETA (0.035g, 0.2mmol) in 6mL DMF, and continuously freeze-thaw and degas Add CuBr (0.029g, 0.2mmol) after 2 times, then freeze-thaw and degas once...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com