Composite material based on polyethylene glycol terephthalate and preparation method thereof

A technology of polyethylene terephthalate and composite materials, applied in the field of modified polyethylene terephthalate, can solve the problems of high finished product molding rate, poor crystallization performance, poor processing performance of PET materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

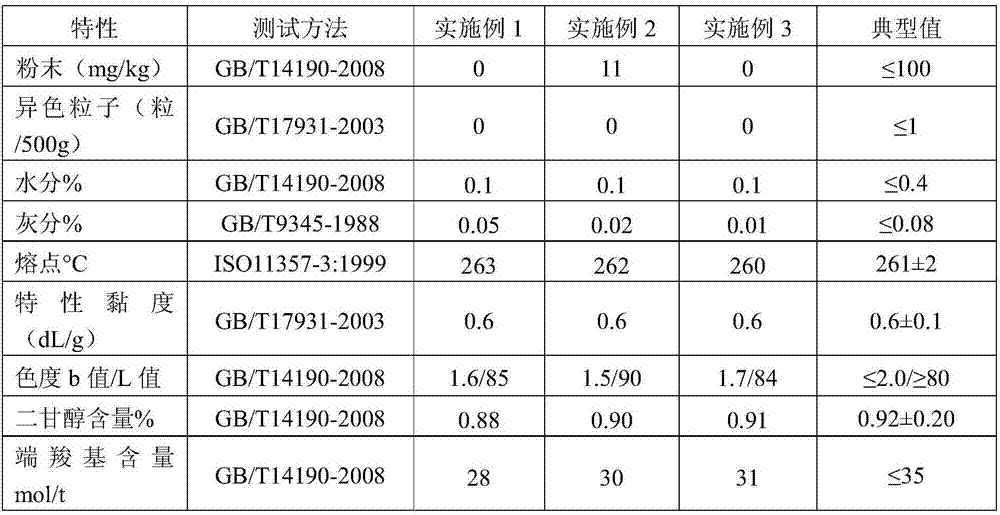

Embodiment 1

[0036] A composite material based on polyethylene terephthalate and a preparation method thereof, comprising the steps of:

[0037] (1) Recrystallization treatment: Inhale 90 parts of PET materials with a vacuum pump in parts by weight, preheat on a fluidized bed, the preheating temperature is 80°C, and the preheating time is 15min, then enter the crystallization tank, stir and crystallize, the temperature is 120°C , the crystallization time is 4h, and PET material 1 is obtained;

[0038](2) Modification treatment: by weight, get 80 parts of PET materials, 5 parts of polyolefin elastomers, 6 parts of aluminum oxide, 6 parts of talcum powder, tetrakis [β-(3,5-di-tert-butyl- 1 part of 4-hydroxyphenyl)propionic acid] pentaerythritol ester (Irganox1010), 1 part of 2-(2H-benzotriazol-2-yl)-4,6-di-tert-amylphenol (Tinuvin 328), chlorinated 1 part of polyethylene wax enters the twin-screw extruder, melts and blends, extrudes and granulates, and the processing temperature is divided ...

Embodiment 2

[0041] A composite material based on polyethylene terephthalate and a preparation method thereof, comprising the steps of:

[0042] (1) Recrystallization treatment: Inhale 95 parts of PET materials with a vacuum pump in parts by weight, preheat on a fluidized bed, the preheating temperature is 80°C, and the preheating time is 15min, then enter the crystallization tank, stir and crystallize, the temperature is 120°C , the crystallization time is 4h, and PET material 1 is obtained;

[0043] (2) Modification treatment: by weight, get 90 parts of PET materials, 3 parts of polyolefin elastomers, 2 parts of aluminum oxide, 2 parts of sodium benzoate, tetrakis [β-(3,5-di-tert-butyl- 1 part of 4-hydroxyphenyl) propionic acid] pentaerythritol ester (Irganox1010), 1 part of 2-(2H-benzotriazol-2-yl)-4,6-di-tert-amylphenol (Tinuvin 328), chlorinated 1 part of polyethylene wax enters the twin-screw extruder, melts and blends, extrudes and granulates, and the processing temperature is divi...

Embodiment 3

[0046] A composite material based on polyethylene terephthalate and a preparation method thereof, comprising the steps of:

[0047] (1) Recrystallization treatment: in parts by weight, suck 99.5 parts of PET materials with a vacuum pump, preheat on a fluidized bed, the preheating temperature is 80°C, and the preheating time is 15min, then enter the crystallization tank, stir and crystallize, and the temperature is 120°C , the crystallization time is 4h, and PET material 1 is obtained;

[0048] (2) Modification treatment: by weight, take 98 parts of PET materials, 1 part of polyolefin elastomer, 0.3 part of magnesium carbonate, 0.4 part of sodium benzoate, tetrakis[β-(3,5-di-tert-butyl-4- 0.1 part of hydroxyphenyl) propionic acid] pentaerythritol ester (Irganox1010), 0.1 part of 2-(2H-benzotriazol-2-yl)-4,6-di-tert-amylphenol (Tinuvin 328), 0.1 part of polyethylene wax Parts, into the twin-screw extruder, melt blending, extrusion granulation, processing temperature is divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com