Anisotropic conductive adhesive film and preparation and application method thereof

An anisotropic, conductive adhesive film technology, used in conductive adhesives, adhesives, epoxy resin adhesives, etc., can solve the problems of uneven conductive particles, open circuits, short circuits, etc., and achieve a simple and controllable preparation method and contact resistance. The effect of value reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

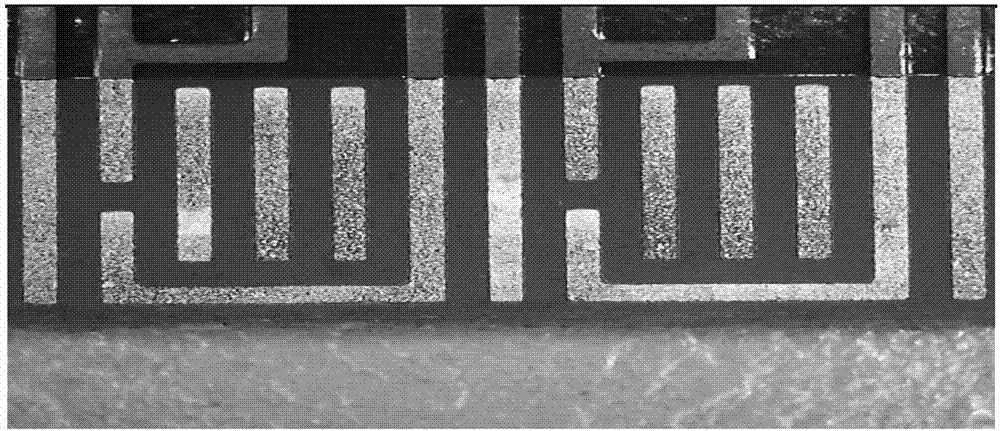

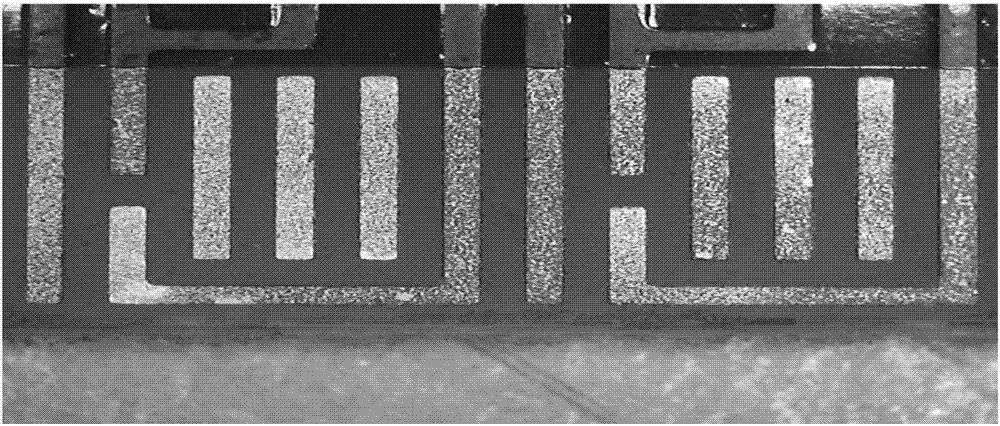

Image

Examples

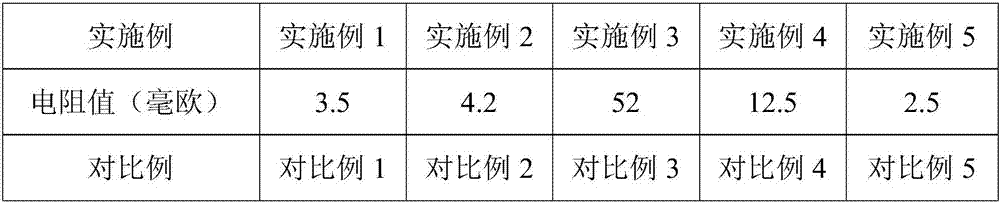

Embodiment 1

[0060] An anisotropic conductive adhesive film, consisting of an epoxy adhesive film and conductive particles with a median particle size of 3 μm, wherein the volume percentage of the conductive particles is 5%, the conductive particles have a core-shell structure, and the conductive particles are made of cross-linked polystyrene The core is plated with nickel and gold.

[0061] Its preparation method is as follows:

[0062] Soak 1g of polymer-nickel-gold core-shell conductive particles in 25mL tetrahydrofuran solvent dissolved with 1g of tetrakis(3-mercaptopropionate)pentaerythritol ester monomer. Wash clean and set aside. Similar to the modification of conductive particles, soak the PCB board with metal wires in the same composition of tetrahydrofuran solvent for 24 hours. Then, after washing with tetrahydrofuran and absolute ethanol in sequence, add 50 mL of absolute ethanol, and add the above-mentioned modified conductive particles, and shake the solvent every 10 minutes...

Embodiment 2

[0064] An anisotropic conductive adhesive film, consisting of an epoxy adhesive film and conductive particles with a median particle size of 10 μm, wherein the volume percentage of the conductive particles is 15%, the conductive particles have a core-shell structure, and are cross-linked with polymethacrylic acid Methyl ester is the core, and the surface of the core is plated with nickel and gold.

[0065] Its preparation method is as follows:

[0066] Soak 1g of polymer-nickel-gold core-shell conductive particles in 25mL of anhydrous alcohol solvent dissolved with thioglycolic acid, soak for 12 hours at room temperature, settle and separate, wash with absolute ethanol in turn, and set aside. Similar to the conductive particle modification, soak the PCB board with metal wires in 10% L-cysteine absolute ethanol solvent for 24 hours. Then, after washing with absolute ethanol in sequence, pour into 50 mL of absolute ethanol, and add the above-mentioned modified conductive part...

Embodiment 3

[0068] An anisotropic conductive adhesive film, consisting of an epoxy adhesive film and conductive particles with a median particle size of 50 μm, wherein the volume percentage of the conductive particles is 2%, the conductive particles have a core-shell structure, and are cross-linked with polymethacrylic acid Methyl ester is the nucleus, and the surface of the nucleus is plated with silver.

[0069] Its preparation method is as follows:

[0070] Soak 0.003g of polymer-silver core-shell conductive particles in 25mL of anhydrous alcohol solvent dissolved with 30wt% thioglycolic acid, soak for 2 hours at room temperature, settle and separate, wash with absolute ethanol in turn, and set aside. Similar to the conductive particle modification, the PCB board with the metal wire is soaked in 0.5wt% L-cysteine absolute ethanol solvent for 48 hours. Then, after successively washing with absolute ethanol, add 50 mL of absolute ethanol, and add the above-mentioned modified conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com