Fluorine-containing anti-corrosion silicone adhesive and preparation method thereof

An organic silica gel, corrosion-resistant technology, applied in the direction of adhesives, adhesive additives, epoxy resin glue, etc., can solve the problems of low adhesion, small solubility parameters of fluorine-containing materials, poor adhesion performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

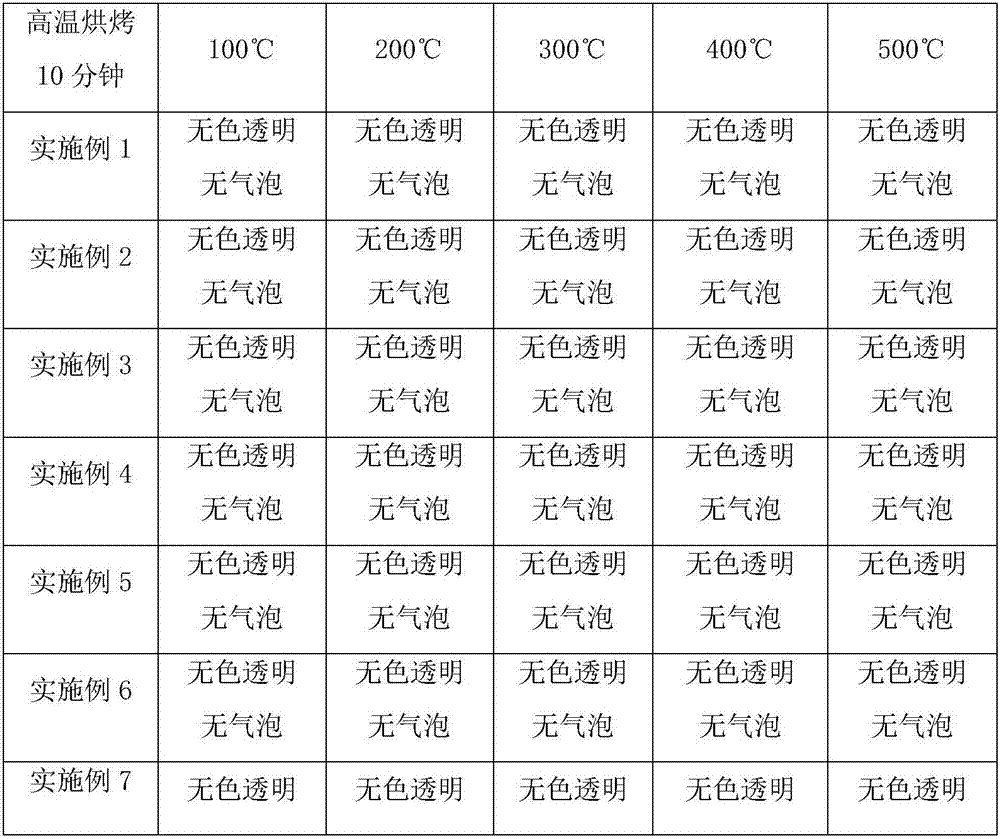

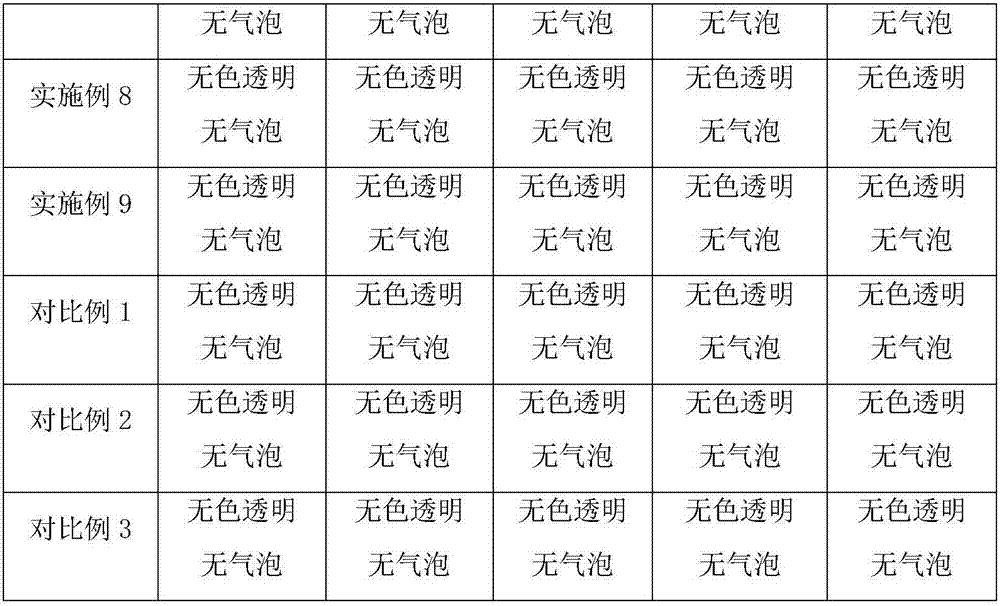

Examples

Embodiment 1

[0017] Weigh 35 parts of fluorine-containing compound perfluoromethyl methacrylate, 10 parts of amine compound N'N-4,4'-dibenzomethane type bismaleimide resin (BMI), epoxy resin compound ethylene bisphenol 30 parts of F-type epoxy resin, 25 parts of phenyl hydrogen-containing silicone resin, 2 parts of toughening agent carboxyl liquid nitrile rubber, 0.001 part of catalyst triethylenetetraammonia, add to the reaction device under the protection of inert gas, stir and then add to solidify 1.5 parts of m-phenylenediamine, heated to 40°C, continued to stir for 20 minutes, cooled to room temperature to obtain a colorless transparent liquid, removed air bubbles under reduced pressure, heated and solidified at 50°C for 30 minutes, and the organic Silicone adhesive.

Embodiment 2

[0019] Weigh 42 parts of fluorine-containing compound perfluoromethyl methacrylate, 15 parts of amine compound N'N-4,4'-dibenzomethane type bismaleimide resin (BMI), epoxy resin compound quinone 35 parts of type epoxy resin, 35 parts of phenyl hydrogen-containing silicone resin, 2 parts of polysulfide rubber as toughening agent, and 0.005 part of catalyst triethylenetetraammonia. 1.3 parts of diamine, heated to 45°C, continued to stir for 25 minutes, cooled to room temperature to obtain a colorless transparent liquid, removed air bubbles under reduced pressure, heated and solidified at 60°C for 30 minutes, and the silicone adhesive was prepared .

Embodiment 3

[0021] Weigh 40 parts of fluorine-containing compound perfluoromethyl methacrylate, 13 parts of amine compound N'N-4,4'-dibenzyme type bismaleimide resin (BMI), epoxy resin compound tetraphenol group 28 parts of ethane-type epoxy resin, 35 parts of phenyl hydrogen-containing silicone resin, 4 parts of toughening agent liquid silicone rubber, 0.003 part of catalyst triethylenetetraammonia, add to the reaction device under the protection of inert gas, add curing agent after stirring 1.9 parts of m-phenylenediamine, heated to 50°C, continued to stir for 30 minutes, cooled to room temperature to obtain a colorless transparent liquid, removed air bubbles under reduced pressure, heated and solidified at 70°C for 30 minutes, and the organic silica gel was obtained adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com