A kind of graphene and quasicrystal composite strengthened magnesium-based composite material and preparation method thereof

A composite material and graphene technology, applied in the field of metal composite materials, can solve problems such as lack of good solutions, and achieve the effects of avoiding the formation of bad interface compounds, effectively combining, and improving strength and elastic modulus.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the magnesium-based composite material strengthened by graphene and quasicrystal composite of the present invention, the steps are as follows:

[0037] (1) Preparation of Mg-Zn-Gd-Ca-Al alloy containing quasi-crystalline strengthening phase: The steps to prepare Mg-Zn-Gd-Ca-Al alloy by smelting process are as follows:

[0038] 1) Ingredients: The raw materials are pure Mg, pure Zn, pure Ca, pure Al, Mg-30wt.%Gd master alloy, and the ingredients are formulated according to the mass percentage;

[0039] 2) Baking material: take pure Mg, pure Zn, pure Ca, pure Al, Mg-30wt.%Gd master alloy, and preheat at 180~250℃ for more than 3 hours;

[0040] 3) Melting Mg, Zn and Ca: Melt the dried pure magnesium in a crucible resistance furnace. After the pure magnesium ingot is melted, add pure zinc at 670~700°C; after the pure zinc is melted, the melt temperature rises to 700 Add pure calcium at ~740℃;

[0041] 4) Add Gd and Al: After the pure calcium is m...

Embodiment 1

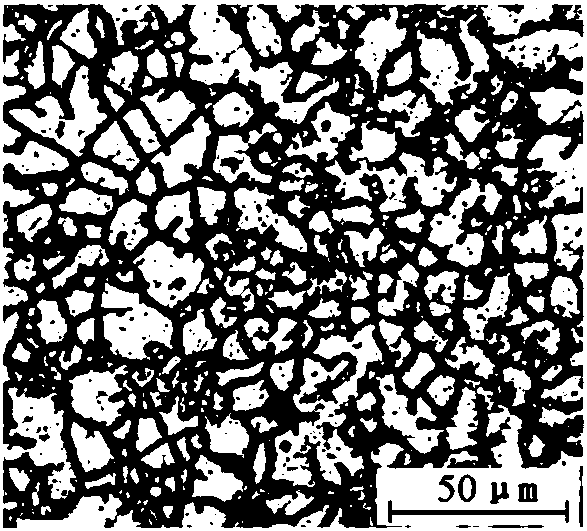

[0050] The magnesium-based composite material strengthened by graphene and quasicrystal composite in this embodiment is prepared by adding graphene into the magnesium alloy matrix containing quasicrystal strengthening phase, and the magnesium alloy matrix containing quasicrystal strengthening phase is made of magnesium alloy Powder and magnesium alloy plate composition, wherein, the mass ratio of graphene and magnesium alloy powder is 1:2, the mass ratio of graphene and magnesium alloy powder as a whole and magnesium alloy plate is 1:5; The components and their mass percentages are: 2wt.%Zn, 1wt.%Gd, 0.5wt.%Ca, 0.5wt.%Al, and the balance is Mg. The above-mentioned components are prepared by smelting process to obtain quasi-crystal strengthening phase Mg-2Zn-1Gd-0.5Ca-0.5Al alloy, Mg-2Zn-1Gd-0.5Ca-0.5Al alloy is powdered by atomization method to obtain magnesium alloy powder, and Mg-2Zn-1Gd-0.5Ca-0.5Al alloy is used The homogenization treatment obtains the magnesium alloy plate...

Embodiment 2

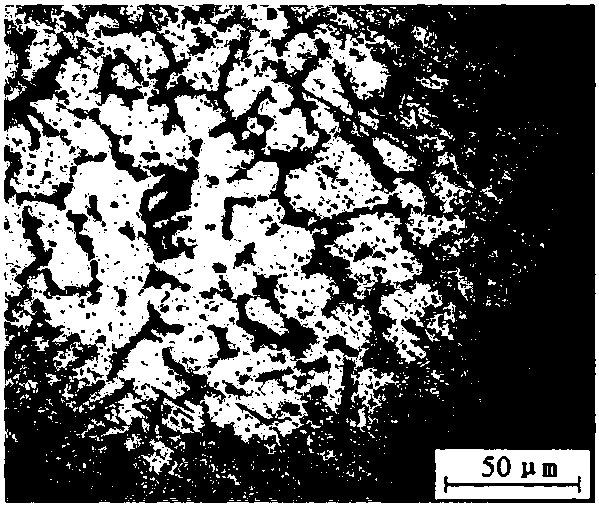

[0066] The magnesium-based composite material strengthened by graphene and quasicrystal composite in this embodiment is prepared by adding graphene into the magnesium alloy matrix containing quasicrystal strengthening phase, and the magnesium alloy matrix containing quasicrystal strengthening phase is made of magnesium alloy Powder and magnesium alloy plate composition, wherein, the mass ratio of graphene and magnesium alloy powder is 1:4, the mass ratio of graphene and magnesium alloy powder as a whole and magnesium alloy plate is 1:8; The components and their mass percentages are: 8wt.%Zn, 4wt.%Gd, 2.5wt.%Ca, 2.5wt.%Al, and the balance is Mg. The above-mentioned components are prepared by smelting process to obtain quasi-crystal strengthening phase Mg-8Zn-4Gd-2.5Ca-2.5Al alloy, Mg-8Zn-4Gd-2.5Ca-2.5Al alloy is powdered by atomization method to obtain magnesium alloy powder, and Mg-8Zn-4Gd-2.5Ca-2.5Al alloy is used The homogenization treatment obtains the magnesium alloy plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com