A spiral formed x80 steel grade riser main pipe and its manufacturing method

A spiral forming and manufacturing method technology, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., to achieve the effect of improving low temperature toughness and weld strength, good corrosion resistance and weldability, and reducing low temperature embrittlement transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Example: A manufacturing method for the main pipe of an X80 steel grade Ф533×25.4 mm spirally formed marine riser.

[0027] 1) Raw materials: X80 steel grade 1140×25.4mm steel coils are used, and the chemical composition analysis of the coils is as follows:

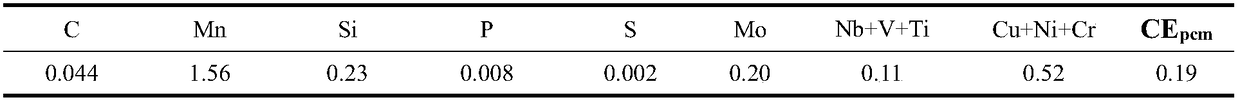

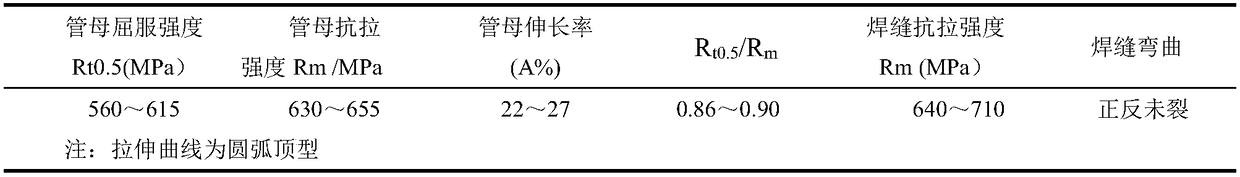

[0028] Table 1 Analysis of chemical composition of main pipe of X80 Ф533×25.4mm spiral-formed marine riser (wt%)

[0029]

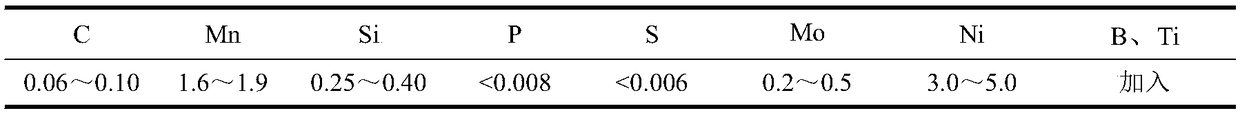

[0030] Table 2 Chemical composition analysis of high Ni welding wire for marine riser (wt%)

[0031]

[0032] 2) Edge milling: After edge milling, the angle of the up-groove is 60°, the angle of the down-groove is 60°, and the height of the blunt edge is 11mm.

[0033] 3) Forming: According to the actual yield strength level of the coil, the external control forming method is adopted to precisely measure and control the position and angle of each forming roller, and adjust the angle of the turntable to 45°50', the angle of the inner roll to 45°5', and the angle of the outer roll It is 45...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com