Pt-based octahedral nanocrystal cathode catalyst used for vehicle-mounted fuel cell and preparation method for cathode catalyst

A cathode catalyst and fuel cell technology, applied in fuel cells, power system fuel cells, nanotechnology for materials and surface science, etc., can solve the problem of poor uniformity of nanocrystal morphology, easy agglomeration, uneven dispersion of nanocrystals, etc. problems, to achieve the effect of excellent electrochemical performance, good dispersion and uniform catalyst structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

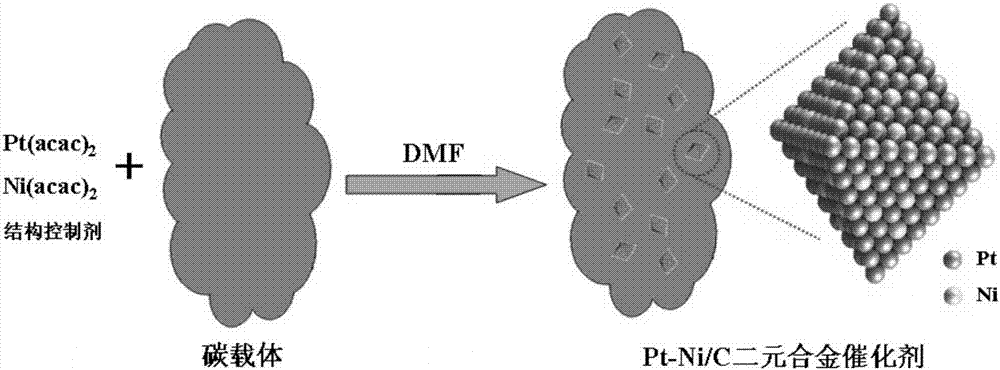

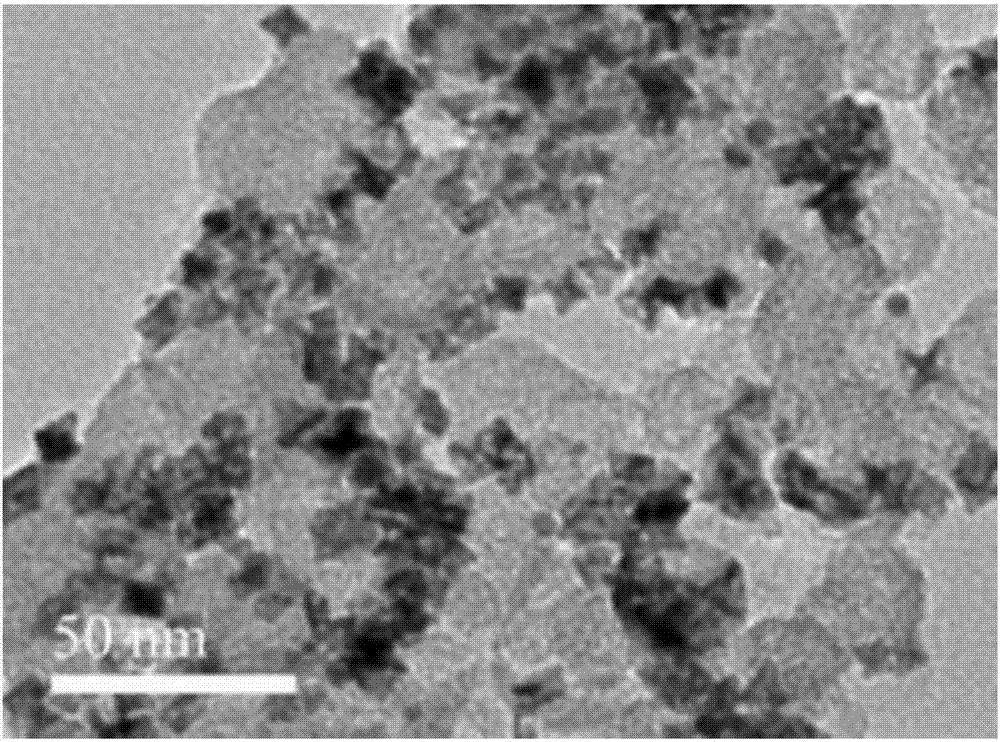

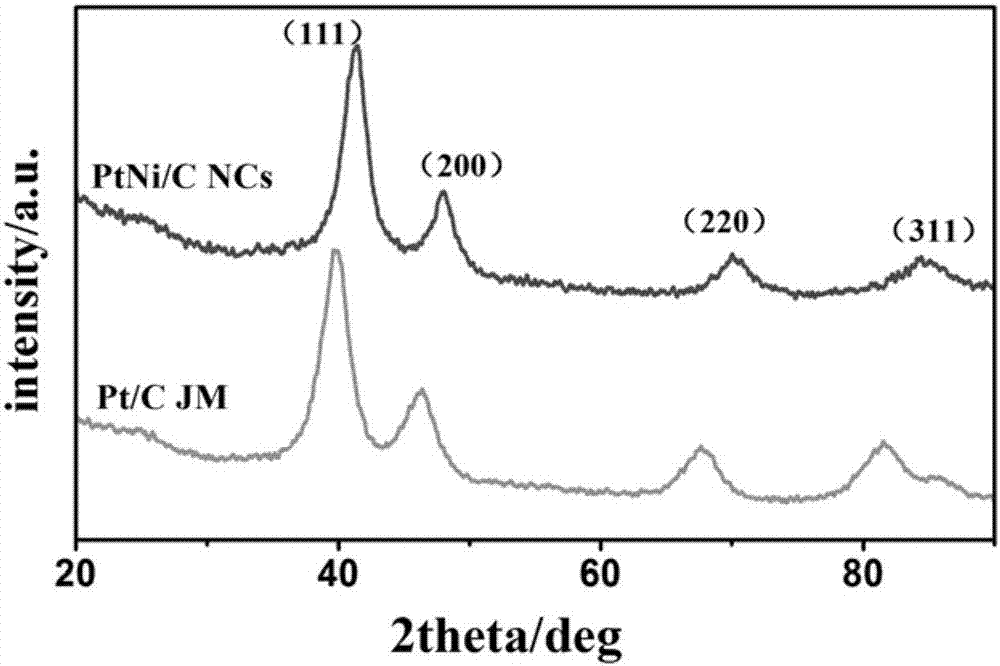

[0036] Using CTAB as a Pt-based octahedral nanocrystal cathode catalyst prepared by a structure control agent, its preparation method can be found in figure 1 shown.

[0037] Pt(acac) 2 , Ni(acac) 2 , CTAB was dissolved in a certain volume of DMF; another certain volume of DMF was taken (to make the total volume of DMF taken twice be 70mL, and to make Pt(acac) 2 、Ni(acac) 2 , CTAB concentrations are 4mM, 10mM, 4mM respectively), add 0.081g of Vulcan XC-72R carbon carrier, ultrasonic 30min to make it uniformly dispersed; mix the above separately dispersed solutions, ultrasonically disperse for 30min. Pour the above solution into a 100mL stainless steel autoclave lined with polytetrafluoroethylene, pressurize and seal it, place it in an oven, heat it from room temperature to 160°C, and react for 12h. After the reaction was complete, the autoclave was cooled to ambient temperature. The colloidal solution after the reaction was suction-filtered through a sand core funnel to o...

Embodiment 2

[0040] Pt-Based Octahedral Nanocrystalline Cathodic Catalysts Prepared Using Benzoic Acid as Structure Controlling Agent

[0041] Pt(acac) 2 , Ni(acac) 2 , benzoic acid is dissolved in a certain volume of DMF; another certain volume of DMF is taken (to make the total volume of DMF measured twice is 70mL, and to make Pt(acac) 2 、Ni(acac) 2 , benzoic acid concentrations are 2mM, 1.5mM, 5mM), add 0.14g of Vulcan XC-72R carbon carrier, ultrasonic 30min to make it uniformly dispersed; mix the above separately dispersed solutions, ultrasonically disperse for 30min. Pour the above solution into a 100mL stainless steel autoclave lined with polytetrafluoroethylene, pressurize and seal it, place it in an oven, heat it from room temperature to 160°C, and react for 12h. After the reaction was complete, the autoclave was cooled to ambient temperature. The colloidal solution after the reaction was suction-filtered through a sand core funnel to obtain a solid product, and then washed wit...

Embodiment 3

[0044] Pt-based octahedral nanocrystalline cathode catalysts prepared with CTAB as structure control agent

[0045] Pt(acac) 2 、Ni(acac) 2 , CTAB was dissolved in a certain volume of DMF, and another certain volume of DMF was taken (to make the total volume of DMF measured twice to be 70mL, and to make Pt(acac) 2 、Ni(acac) 2 , CTAB concentrations are 4mM, 10mM, 4mM), add 0.2g of Vulcan XC-72R carbon carrier, ultrasonic 30min to make it uniformly dispersed; mix the above separately dispersed solutions, ultrasonically disperse for 30min. Pour the above solution into a 100mL stainless steel autoclave lined with polytetrafluoroethylene, pressurize and seal it, place it in an oven, heat it from room temperature to 150°C, and react for 14h. After the reaction was complete, the autoclave was cooled to ambient temperature. The colloidal solution after the reaction was suction-filtered through a sand core funnel to obtain a solid product, then washed with ethanol and high-purity wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com