Photocatalytic air purification sticker preparation method

A technology for purifying gas and sticky notes, applied in the field of air purification, can solve problems such as easy peeling off of catalyst coating, and achieve the effect of improving atmospheric safety and comfort, no operating costs, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

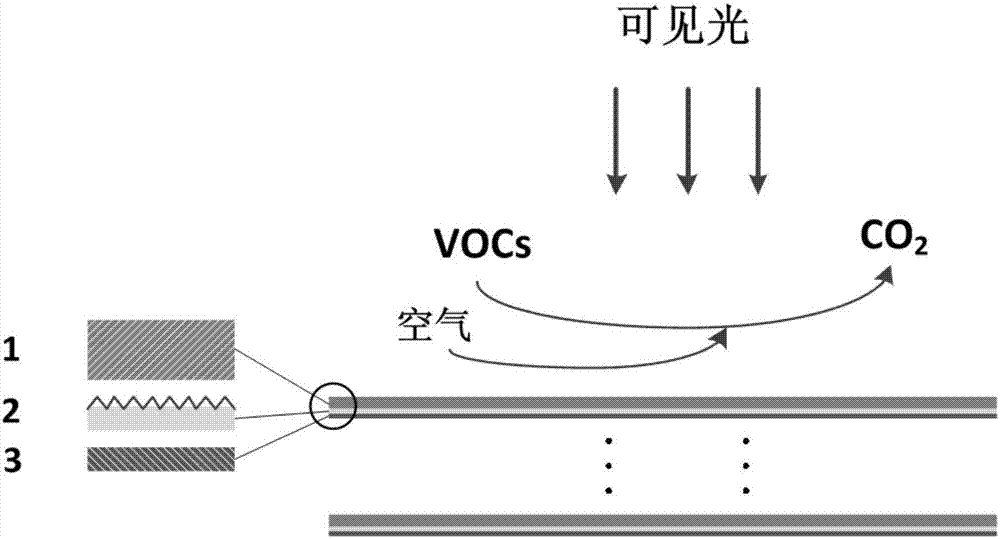

Image

Examples

Embodiment 1

[0023] Step 1 (impregnation), using improved impregnation method to prepare 1wt% Au / TiO 2 catalyst of light. (1) Take an appropriate amount of 2.4×10 - 2 The mol / L chloroauric acid solution was poured into the TiO 2 (P25, Deggusa) powder in a beaker, using a glass rod to stir for 5 minutes; (2) immersion in the dark for 12 hours; (3) washing the catalyst with ammonia water and deionized water respectively, and separating the solid-liquid phase by a centrifuge, in order to further Thoroughly remove chloride ions, and repeat this step again; (4) put the washed catalyst into an oven at 80° C. to dry for 8 hours, and store it in a refrigerator away from light.

[0024] In step 2 (substrate treatment), the 2.5cmx2.5cm ordinary glass sheet is treated by oxygen plasma method.

[0025] Step 3 (coating and activation), take 1.8g deionized water and add to 0.135g Au / TiO 2 In the powder, stir on a magnetic stirrer for 15 minutes; take 0.215 mg of the turbid liquid and drop it evenly...

Embodiment 2

[0028] Adopt the catalyst preparation method in the step one of embodiment 1, prepare fresh 3%Au / TiO 2 catalyst of light. Using the base treatment method in step 2 of Example 1, the polyimide base film was treated with oxygen plasma. Adopt the catalyst coating method in the step 3 of embodiment 1, prepare Au / TiO 2 coating. Activate the catalyst coating with oxygen plasma, apply non-stick adhesive on the other side, and finally get a post-it note for photocatalytic purification of gas. Stick it on the wall of the living room, choose to start the fan at noon when the incident light intensity of the sun is the highest, and start the humidifier at the same time when the humidity is low, so as to purify the indoor air with photocatalysis.

Embodiment 3

[0030] Adopt the catalyst preparation method in the step one of embodiment 1, prepare fresh Au / SiO 2 catalyst of light. Argon plasma treatment was performed on the substrate polyethylene film. Adopt the catalyst coating method in the step 3 of embodiment 1, prepare Au / SiO 2 coating. Activate the catalyst coating with oxygen plasma, apply non-stick adhesive on the other side, and finally get a post-it note for photocatalytic purification of gas. Stick it on the wall of the bathroom, turn on the fluorescent lamp, start the ventilation fan, and purify the indoor air with photocatalysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com