Method of removing odors in refined salt

A technology for refining salt and odor, applied in the field of salt chemical industry, can solve problems such as hindering the healthy development of the salt industry economy, unpleasant smell of salt products, etc., and achieve the effects of stable treatment effect, easy industrial production, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

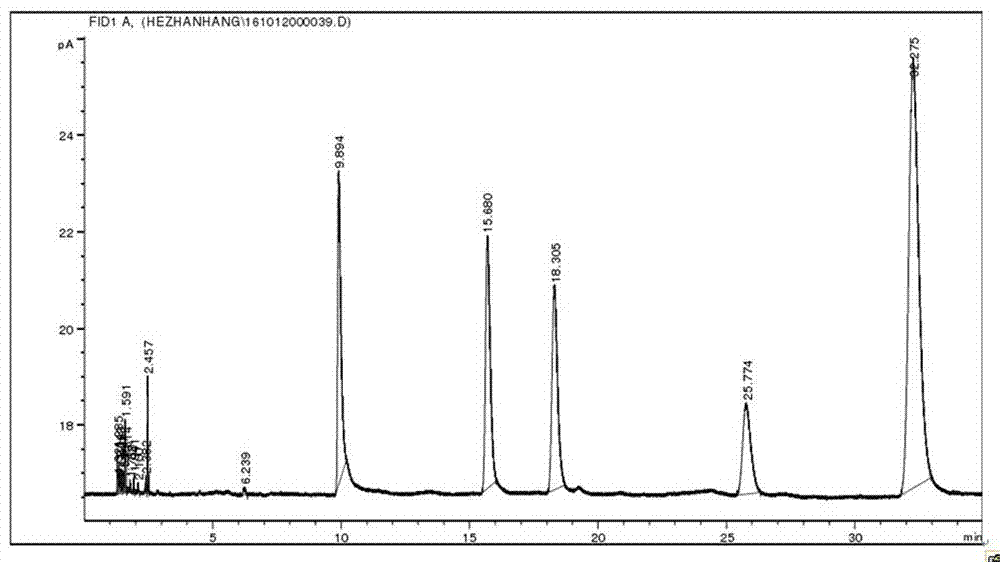

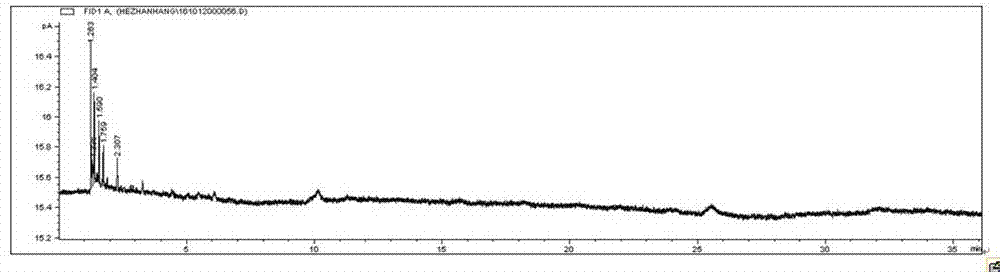

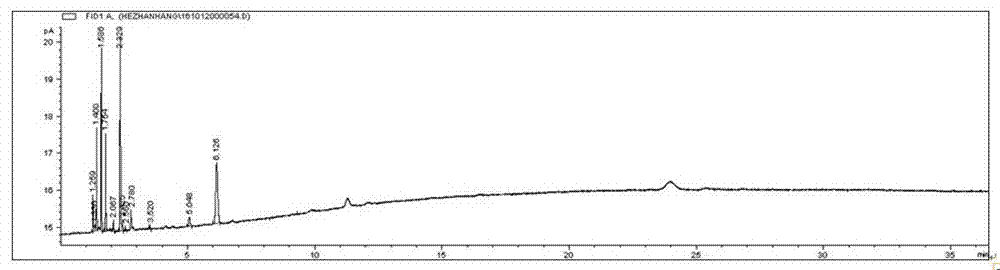

Image

Examples

Embodiment 1

[0041] The present invention removes the method for peculiar smell in refined salt, and the detailed steps of this method are as follows:

[0042] A, at first the hydrochloric acid that mass percentage concentration is 36% is diluted with water to become the dilute hydrochloric acid that mass percentage concentration is 7%, under the condition of constantly stirring, gained dilute hydrochloric acid 4.5g is joined in the 500g refined edible salt that takes by weighing, Stir well until the two are evenly mixed to obtain a mixture;

[0043] B. Under the condition of stirring, add 3.5 g of aqueous hydrogen peroxide solution with a mass percentage concentration of 27.5% and 5 g of an aqueous sodium chlorite solution with a mass percentage concentration of 10% to the mixture obtained in step a and mix evenly. Finally, put it into an oven with a preset temperature of 75°C and set the drying temperature;

[0044] c. In step b, set the final drying temperature to 105°C and the drying ...

Embodiment 2

[0048] The present invention removes the method for peculiar smell in refined salt, and the detailed steps of this method are as follows:

[0049] A, at first the hydrochloric acid that mass percent concentration is 36% is diluted with water to become the dilute hydrochloric acid that mass percent concentration is 7%, under the condition of constantly stirring, gained dilute hydrochloric acid 2.5g is joined in the 500g refined edible salt that takes by weighing, Stir well until the two are evenly mixed to obtain a mixture;

[0050] B, under the condition of stirring, add mass percent concentration to the mixture obtained in step a and be 27.5% hydrogen peroxide aqueous solution 4.0g and mass percent concentration be 10% sodium chlorite aqueous solution 2.0g to mix evenly, mix After uniformity, put it into an oven with a preset temperature of 60°C, and set the drying temperature;

[0051] c. In step b, set the final drying temperature to 125°C and the drying time to 12 minutes...

Embodiment 3

[0055] The present invention removes the method for peculiar smell in refined salt, and the detailed steps of this method are as follows:

[0056] A, at first the hydrochloric acid that mass percent concentration is 36% is diluted with water into the dilute hydrochloric acid that mass percent concentration is 7%, under the condition of constantly stirring, gained dilute hydrochloric acid 3.2g is joined in the refined edible salt of 500g that takes by weighing, Stir well until the two are evenly mixed to obtain a mixture;

[0057] B, under the condition of stirring, add mass percent concentration to the mixture obtained in step a and be 4.0g of aqueous hydrogen peroxide solution of 27.5% and 2.5g of sodium chlorite aqueous solution of 10% of mass percent concentration and mix uniformly, mix After uniformity, put it into an oven with a preset temperature of 60°C, and set the drying temperature;

[0058] c. In step b, set the final drying temperature to 130°C and the drying time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com