Online diagnosis method of laser welding defects based on spectral information

A technology of laser welding and spectral information, which is applied in laser welding equipment, welding equipment, color/spectral characteristic measurement, etc., can solve the problems of time-consuming, laborious and increasingly demanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

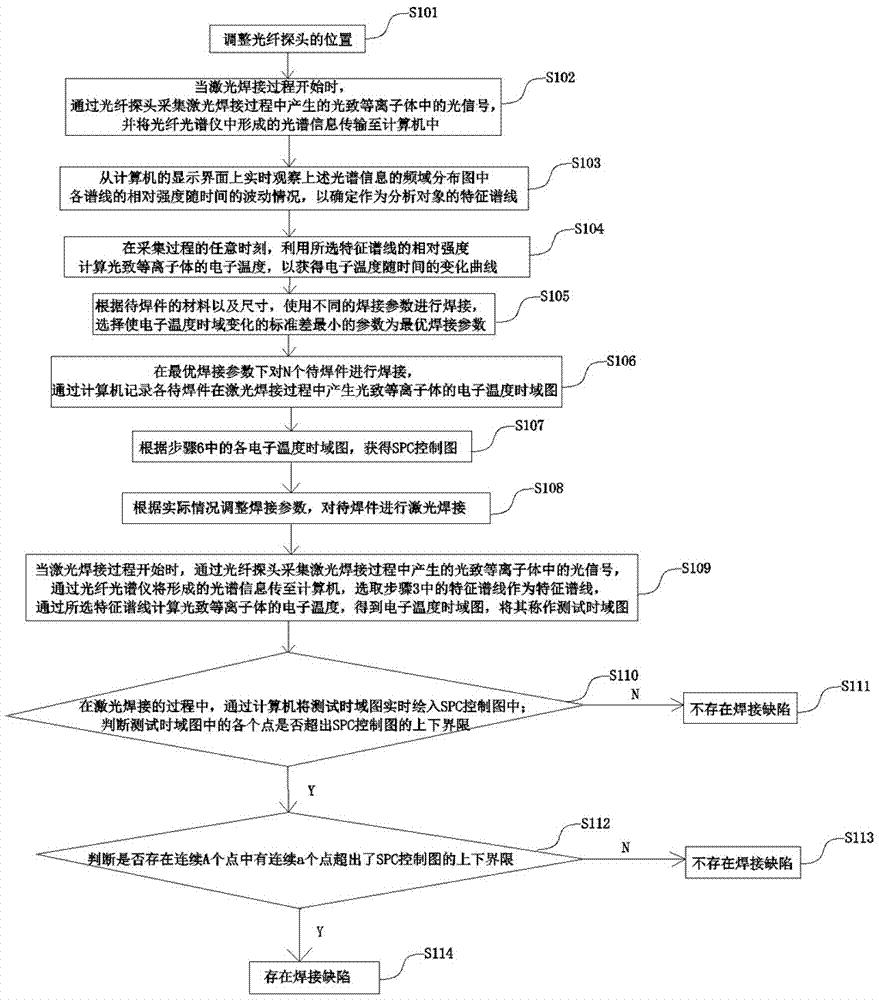

[0062] In this embodiment, the part 6 to be welded is made of 304 stainless steel, and the size of the part 6 to be welded is 100 × 50 × 3 mm. The form of the welded joint and the schematic diagram of the weld seam formed by laser welding are shown in Figure 3 (a) , Protected with Ar shielding gas 8 during the welding process.

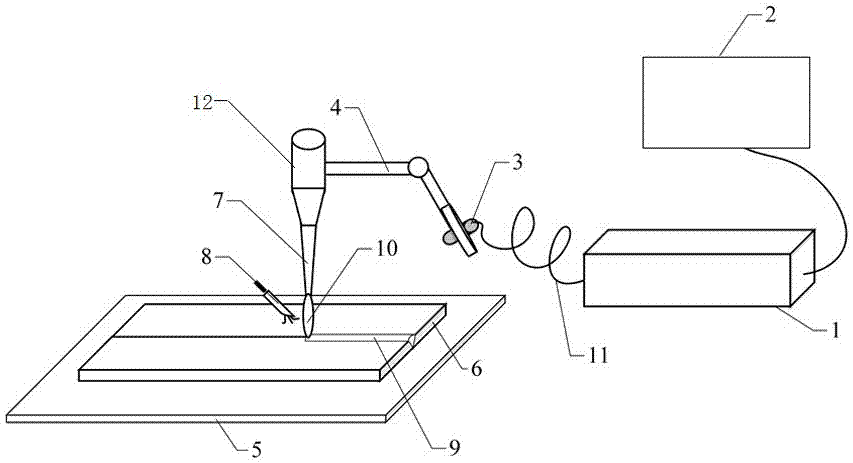

[0063] Adjust the position of the fiber optic probe 3 so that during the laser welding process, the fiber optic probe 3 collects optical signals in the photoplasma with a wavelength of 200-1100 nm, and transmits the spectral information formed in the fiber optic spectrometer 1 to the computer 2 , by comparing the above spectral information, it is determined to use the 318-420nm spectral segment for analysis, so as to collect a spatial map reflecting the relationship between wavelength, time and intensity in the selected spectral segment, as shown in Figure 3(b). For the collected airspace map, based on the principles of high resolution, good profile, h...

Embodiment 2

[0071] In this embodiment, the part 6 to be welded is DX51D+Z galvanized steel sheet E, and the form of the welded joint is a lap joint with a reserved gap, that is, pads D are placed on both ends of the welded joint, and the pads The size of piece D depends on the actual demand, and the schematic diagram of the welding joint and the weld seam formed by laser welding is as follows: Figure 5 As shown, Ar shielding gas was used for protection during the welding process.

[0072]The fixed welding speed v=2.5m / min is unchanged, and different welding parameters are used for welding to determine the optimal welding parameters. At this time, the laser power P=3900W, the gap value is 0.2mm, the defocus is +15mm, Ar protection The air flow is 20L / min. Weld the five parts 6 to be welded under the optimal welding parameters to ensure that there is no accidental disturbance during the welding process and the weld seam is well formed. The computer 2 records the photoplasma generated by e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com