Method for enrichment culture of Anammox

An anammox bacteria and anammox technology are applied in the field of enrichment culture of anammox bacteria, which can solve the problems of long start-up time of anammox reaction and long enrichment culture time, and shorten the start-up time. , The effect of rapid enrichment culture and high microbial concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The method for enriching and cultivating anaerobic ammox bacteria (Anammox) of the present invention will be described in conjunction with examples.

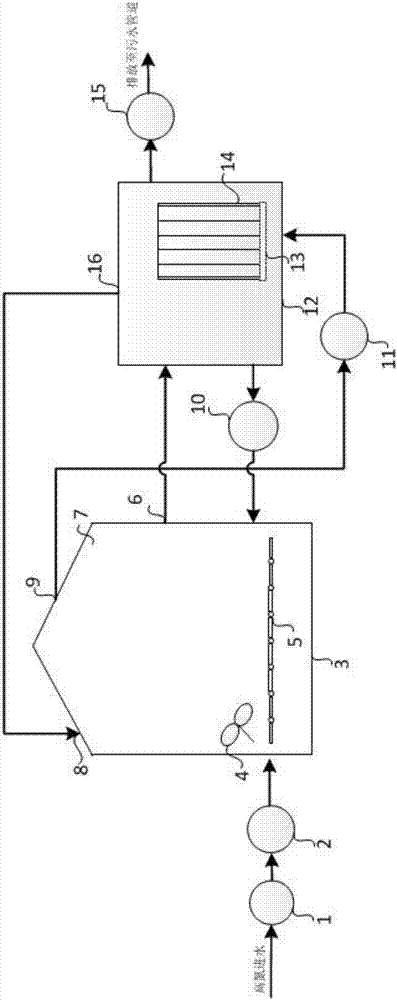

[0017] The design idea of the enrichment culture method for anaerobic ammonia oxidizing bacteria (Anammox) of the present invention is through anaerobic bioreactor+anaerobic MBR membrane bioreactor (AnMBR) system, and described anaerobic bioreactor is a closed chamber, anaerobic bioreactor The oxygen bioreactor includes a gas storage chamber, an agitator, a water distribution distributor, an exhaust port one, an exhaust port two and a thermometer, a pH meter, an ORP meter, and a MLSS meter for detection instruments; the anaerobic MBR membrane bioreactor ( AnMBR) is a closed chamber, and the anaerobic MBR membrane bioreactor (AnMBR) includes an exhaust port, an MBR membrane bioreactor, an aeration pipeline, a thermometer, and a liquid level gauge detection instrument. MBR membrane separation technology has the characteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com