Polyurethane modified epoxy resin and preparation method and electrophoretic coating thereof

A technology of polyurethane modification and epoxy resin, which is applied in the field of preparation of polyurethane modified epoxy resin and polyurethane modified epoxy resin. In order to solve problems such as poor strength, achieve strong metal adhesion, small deformation and shrinkage, and overcome poor weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

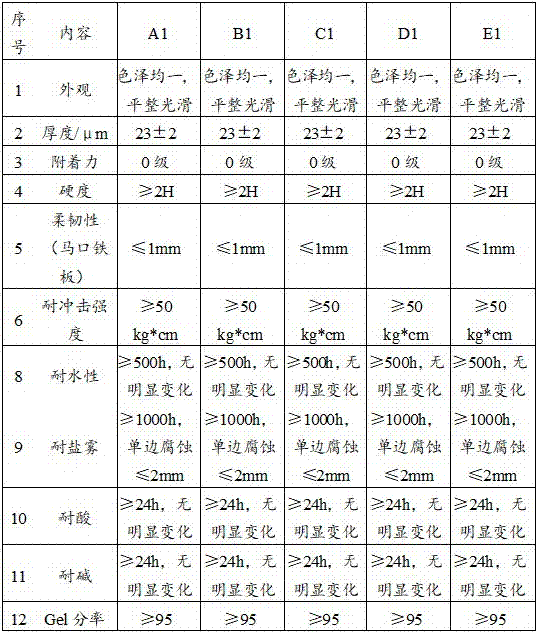

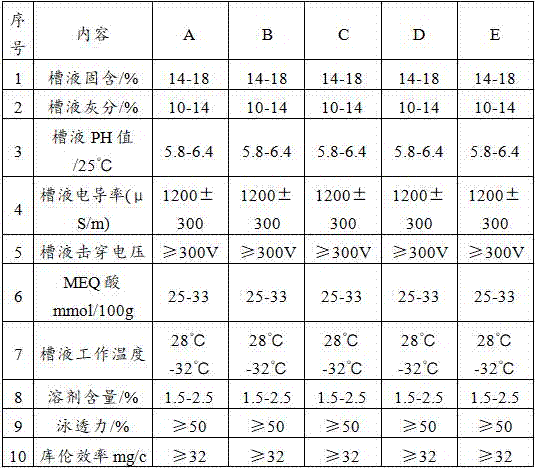

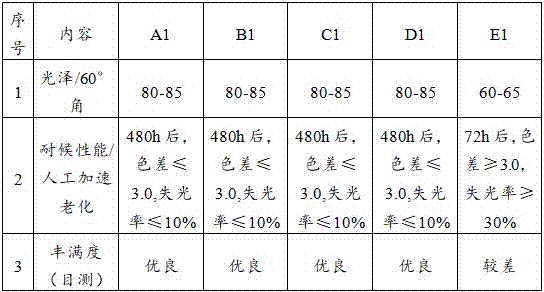

Examples

preparation example Construction

[0063] Correspondingly, the present invention also provides a kind of preparation method of polyurethane modified epoxy resin, comprises the following steps:

[0064] Step 1, take by weight 20-30% epoxy resin, 15-20% toluene diisocyanate, 3-6% polybutylene adipate, 5-10% polyether polyol, 2- 5% dimethylol propionic acid, 0.5-1.5% dibutyltin dilaurate, 4-8% cyclohexanedimethanol, 3-7% propylene glycol methyl ether acetate, 3-7% triethylamine and 15-25 % methyl ethyl ketone, stand-by.

[0065] Step 2: Add epoxy resin, toluene diisocyanate, polybutylene adipate, polyether polyol, butanone and propylene glycol methyl ether acetate into the reaction vessel, and keep warm at 100-120° C. for 2 hours.

[0066] It should be noted that the reaction vessel used in step 2 is a four-neck flask equipped with a stirrer, a reflux condenser, and a thermometer. Therefore, the reactants in step 2 are stirred, refluxed, and reacted at 100-120°C.

[0067] Step 3, after cooling down to 60°C, add di...

Embodiment 1

[0078] 1. Preparation of polyurethane modified epoxy resin

[0079] Step 1, take by weight 25% epoxy resin, 18% toluene diisocyanate, 5% polybutylene adipate, 8% polyether polyol, 2% dimethylol propionic acid, 1 % dibutyltin dilaurate, 6% cyclohexane dimethanol, 5% propylene glycol methyl ether acetate, 7% triethylamine and 23% methyl ethyl ketone, set aside.

[0080] Step 2, adding epoxy resin, toluene diisocyanate, polybutylene adipate, polyether polyol, butanone and propylene glycol methyl ether acetate into the reaction vessel, and keeping the temperature at 100-120° C. for 2 hours;

[0081] Step 3, after cooling down to 60°C, add dibutyltin dilaurate and butanone, and react at 60-80°C for 2 hours under reflux;

[0082] Step 4, after cooling down to 60°C again, add dimethylolpropionic acid, cyclohexanedimethanol, butanone, and reflux at 80-85°C for 4 hours;

[0083] Step 5, after detecting that the isocyanate blocking meets the requirements, slowly add triethylamine drop...

Embodiment 2

[0091] 1. Preparation of polyurethane modified epoxy resin

[0092] Step 1, take by weight 28% epoxy resin, 16% toluene diisocyanate, 6% polybutylene adipate, 10% polyether polyol, 5% dimethylol propionic acid, 1.3 % dibutyltin dilaurate, 7.2% cyclohexanedimethanol, 6.4% propylene glycol methyl ether acetate, 4.1% triethylamine and 16% butanone, set aside.

[0093] Step 2, adding epoxy resin, toluene diisocyanate, polybutylene adipate, polyether polyol, butanone and propylene glycol methyl ether acetate into the reaction vessel, and keeping the temperature at 100-120° C. for 2 hours;

[0094] Step 3, after cooling down to 60°C, add dibutyltin dilaurate and butanone, and react at 60-80°C for 2 hours under reflux;

[0095] Step 4, after cooling down to 60°C again, add dimethylolpropionic acid, cyclohexanedimethanol, butanone, and reflux at 80-85°C for 4 hours;

[0096] Step 5, after detecting that the isocyanate blocking meets the requirements, slowly add triethylamine dropwis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com