Preparation method of low-normal-hexane-dissolution transparent polypropylene material

A technology of transparent polypropylene and n-hexane, applied in the field of preparation of transparent polypropylene materials, can solve the problems of material softening, unfavorable materials, increasing the content of low-molecular random substances, etc., and achieve high transparency and surface gloss, good melting Fluidity and rigidity of the body, increased utilization and added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

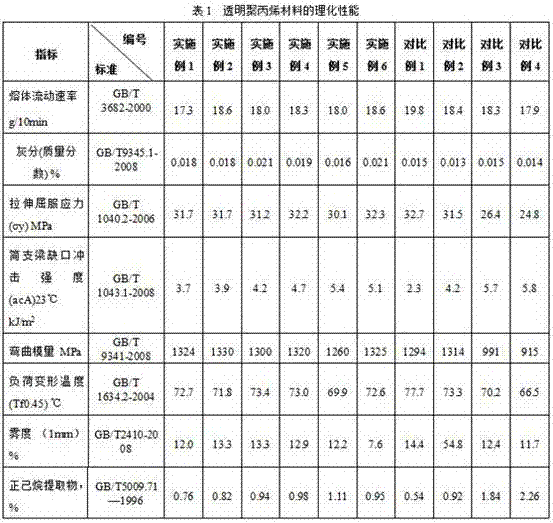

Examples

Embodiment 1

[0026] Add propylene and 1-butene into the loop reactor, and add catalyst DQC-401, cocatalyst triethylaluminum (TEAL), electron donor DONOR-C, antistatic agent Atmer163. Among them: catalyst DQC-401 is added according to the output of 40kg / ton; TEAL / C 3 (Propylene) = 0.16; TEAL / DONOR=5; antistatic agent Atmer163 is 2~3kg / h. Stir evenly, control the reaction temperature in the loop reactor to 70±1°C, the reaction pressure to 3.5MPa, the hydrogen concentration to 2540ppm, and the bonded 1-butene content to 4.3%, so as to obtain the propylene-butylene random copolymerization polypropylene base resin.

[0027] According to the proportion, 99.6% of acrylonitrile-butadiene random copolymerized polypropylene base resin, 0.20% of transparent agent, 0.15% of main and auxiliary antioxidant and 0.05% of halogen absorbent are mixed at normal temperature and pressure for 2 to 4 minutes, and then used The twin-screw extruder is used for granulation, and the temperature is controlled at 160...

Embodiment 2

[0029] Add propylene and 1-butene into the loop reactor, and add catalyst DQC-401, cocatalyst triethylaluminum (TEAL), electron donor DONOR-C, antistatic agent Atmer163. Among them: catalyst DQC-401 is added according to the output of 40kg / ton; TEAL / C 3 (Propylene) = 0.16; TEAL / DONOR=5; antistatic agent Atmer163 is 2~3kg / h. Stir evenly, control the reaction temperature in the loop reactor to 70±1°C, the reaction pressure to 3.7MPa, the hydrogen concentration to 2680ppm, and the bonded 1-butene content to 4.7%, so as to obtain the propylene-butylene random copolymerization polypropylene base resin.

[0030] According to the proportion, 99.6% of acrylonitrile-butadiene random copolymerized polypropylene base resin, 0.20% of transparent agent, 0.15% of main and auxiliary antioxidant and 0.05% of halogen absorbent are mixed at normal temperature and pressure for 2 to 4 minutes, and then used The twin-screw extruder is used for granulation, and the temperature is controlled at 160...

Embodiment 3

[0032] Add propylene and 1-butene into the loop reactor, and add catalyst DQC-401, cocatalyst triethylaluminum (TEAL), electron donor DONOR-C, antistatic agent Atmer163. Among them: catalyst DQC-401 is added according to the output of 40kg / ton; TEAL / C 3 (propylene) = 0.16; TEAL / DONOR=5; antistatic agent Atmer163 is 2~3kg / h. Stir evenly, control the reaction temperature in the loop reactor to 70±1°C, the reaction pressure to 3.7MPa, the hydrogen concentration to 2620ppm, and the bonded 1-butene content to 5.1%, so as to obtain the propylene-butylene random copolymerization polypropylene base resin.

[0033] According to the proportion, 99.6% of acrylonitrile-butadiene random copolymerized polypropylene base resin, 0.20% of transparent agent, 0.15% of main and auxiliary antioxidant and 0.05% of halogen absorbent are mixed at normal temperature and pressure for 2 to 4 minutes, and then used The twin-screw extruder is used for granulation, and the temperature is controlled at 160...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com