Polyacrylonitrile copolymer spinning liquid and preparation method thereof

A technology of polyacrylonitrile and copolymer, which is applied in the field of polyacrylonitrile copolymer spinning solution and its rapid and stable preparation, and can solve the problems of large difference in reactivity ratio, difficulty in mass transfer and heat transfer, inconsistent composition of copolymers, etc. problems, to achieve the effect of enhanced mass transfer and heat transfer, continuous and stable reaction, and uniform composition distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

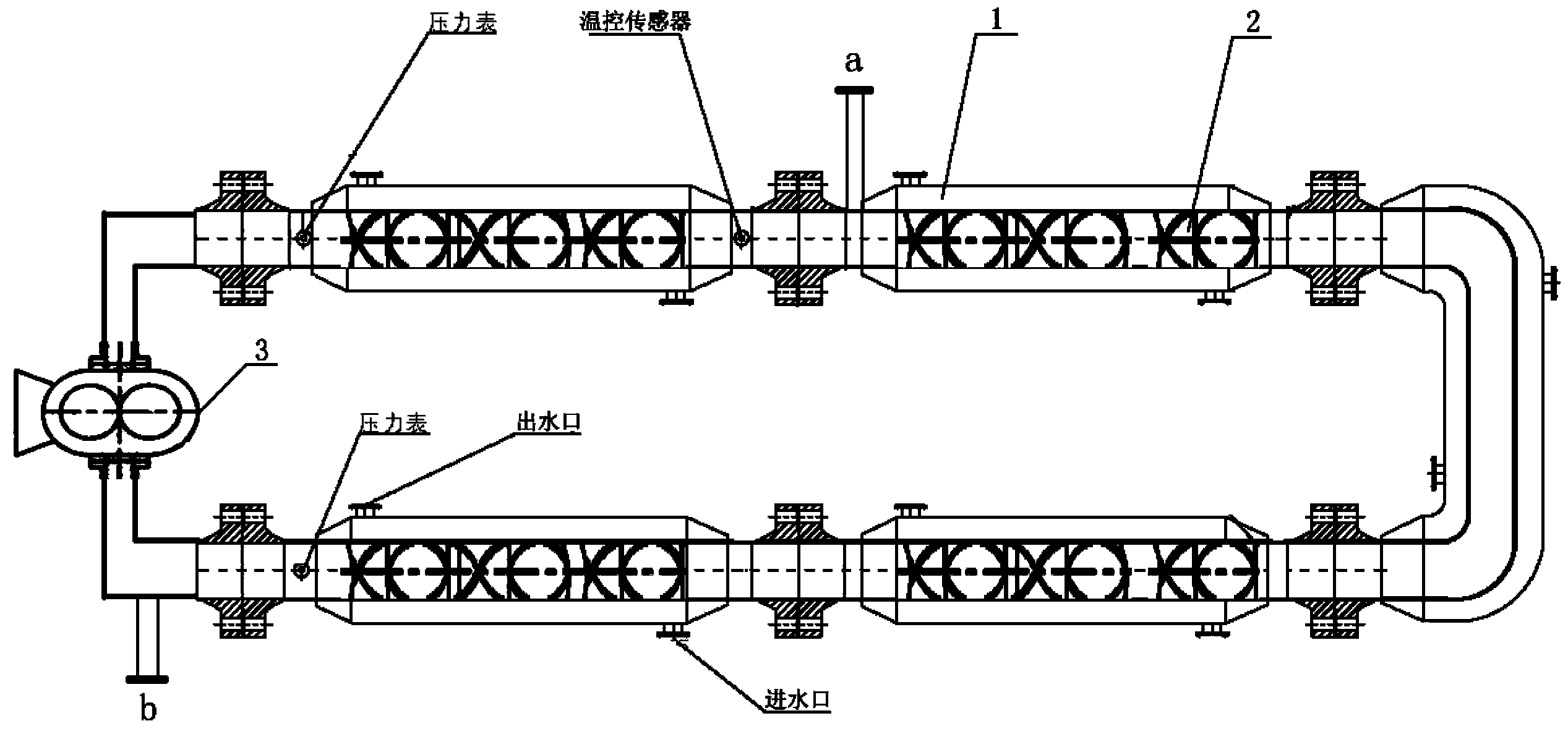

[0059] Such as figure 1 As shown, the tubular reactor containing the static mixer assembly includes a circular pipe with a static mixer assembly 2 installed in a circular pipe made of stainless steel, and a circular pipe with a ring jacket 1 installed outside the circular pipe and an internal circulation pump 3, etc.; and connect four circular tubes in series through a flange installed on the circular tube in the tubular reactor to form a four-section tubular reaction containing a static mixer assembly device.

[0060] One end of the first circular tube in the tubular reactor containing the static mixer assembly combined into four sections is connected with one end of the internal circulation pump 3 through a pipeline, and a pressure gauge; the second circular tube connected in series with the first circular tube is equipped with a temperature control sensor, and is provided with a raw material inlet a; the other end of the internal circulation pump 3 passes through the tube ...

Embodiment 2

[0079]The preparation of the polyacrylonitrile copolymer spinning solution was carried out using the tubular reactor containing the static mixer assembly of Example 1.

[0080] (1) Accurately weigh 26.8Kg of solvent dimethyl sulfoxide, 10.64Kg of acrylonitrile, and 560g of monomethyl itaconate into a stainless steel batching kettle with a mechanical stirring device, stir and mix at room temperature for about 30 minutes, and In the process of stirring and mixing, use nitrogen bubbles to evacuate and remove oxygen;

[0081] (2) Accurately weigh 2Kg of the solvent dimethyl sulfoxide and 67.2g of the free radical initiator azobisisoheptanonitrile and add them to the container, stir rapidly at room temperature to dissolve;

[0082] (3) Under nitrogen protection and stirring, put the free radical initiator solution prepared in step (2) into the batching kettle of step (1) at one time, stir and mix rapidly at room temperature for 2 minutes to obtain a reaction solution;

[0083] (4)...

Embodiment 3

[0086] The preparation of the polyacrylonitrile copolymer spinning solution was carried out using the tubular reactor containing the static mixer assembly of Example 1.

[0087] (1) Accurately weigh 30.2Kg of solvent dimethyl sulfoxide, 8.624Kg of acrylonitrile, and 176g of monomethyl itaconate into a stainless steel batching kettle with a mechanical stirring device, stir and mix at room temperature for about 30 minutes, and In the process of stirring and mixing, use nitrogen bubbles to evacuate and remove oxygen;

[0088] (2) Accurately weigh 1Kg of the solvent dimethyl sulfoxide and 79.2g of the free radical initiator azobisisobutyronitrile into the container, and stir rapidly at room temperature to dissolve;

[0089] (3) Under nitrogen protection and stirring, put the free radical initiator solution prepared in step (2) into the batching kettle of step (1) at one time, stir and mix rapidly at room temperature for 2 minutes to obtain a reaction solution;

[0090] (4) Use th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com