Tungsten trioxide/vanadium pentoxide core-shell-structured nanowire array electrochromic material and preparation method thereof

A technology of vanadium pentoxide core-shell nanometer and electrochromic materials, which is applied in the direction of color-changing fluorescent materials, chemical instruments and methods, nanotechnology, etc., and can solve the problems of small conductivity, lithium ion diffusion coefficient, poor cycle stability, and low coloring efficiency and other problems, to achieve the effect of speeding up the reaction kinetics process, improving the contrast, and controlling the film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

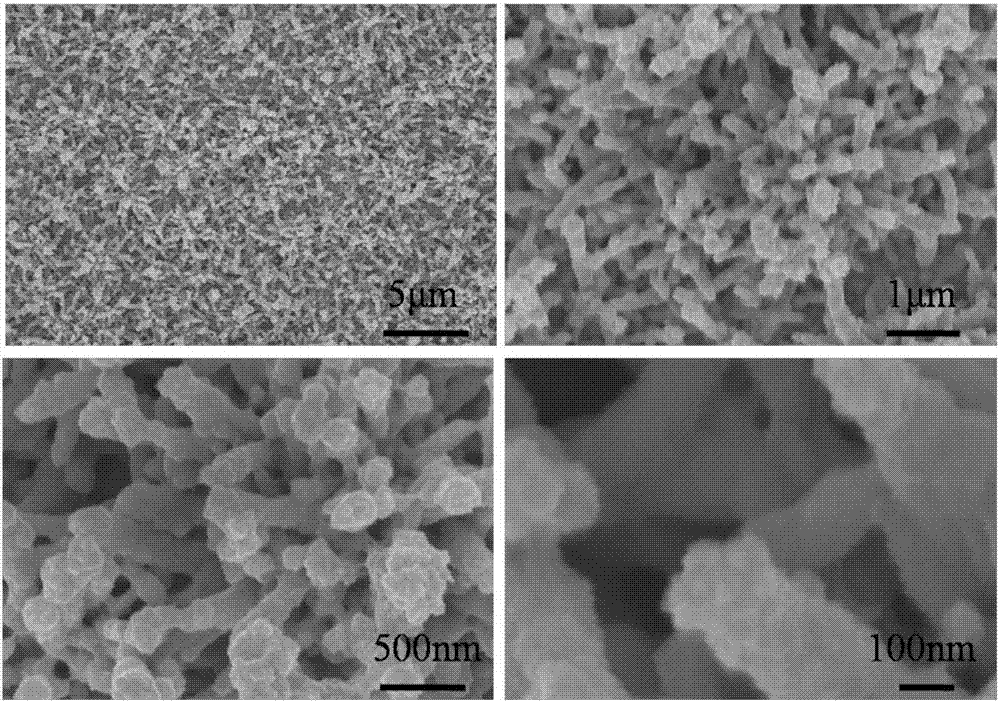

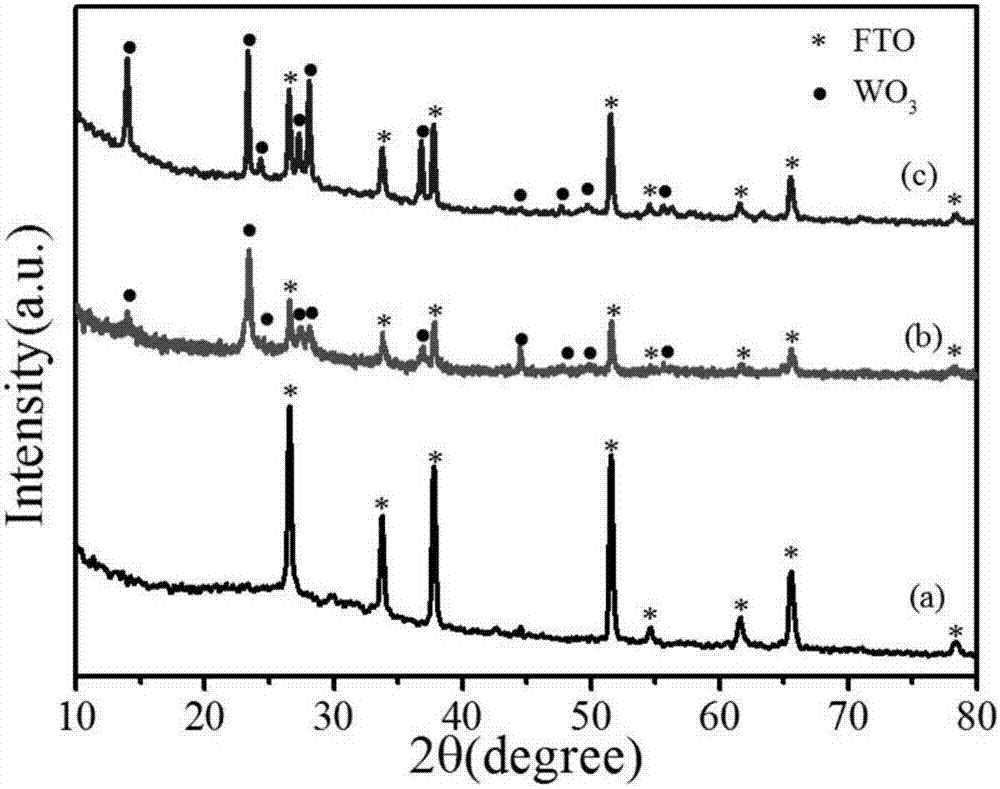

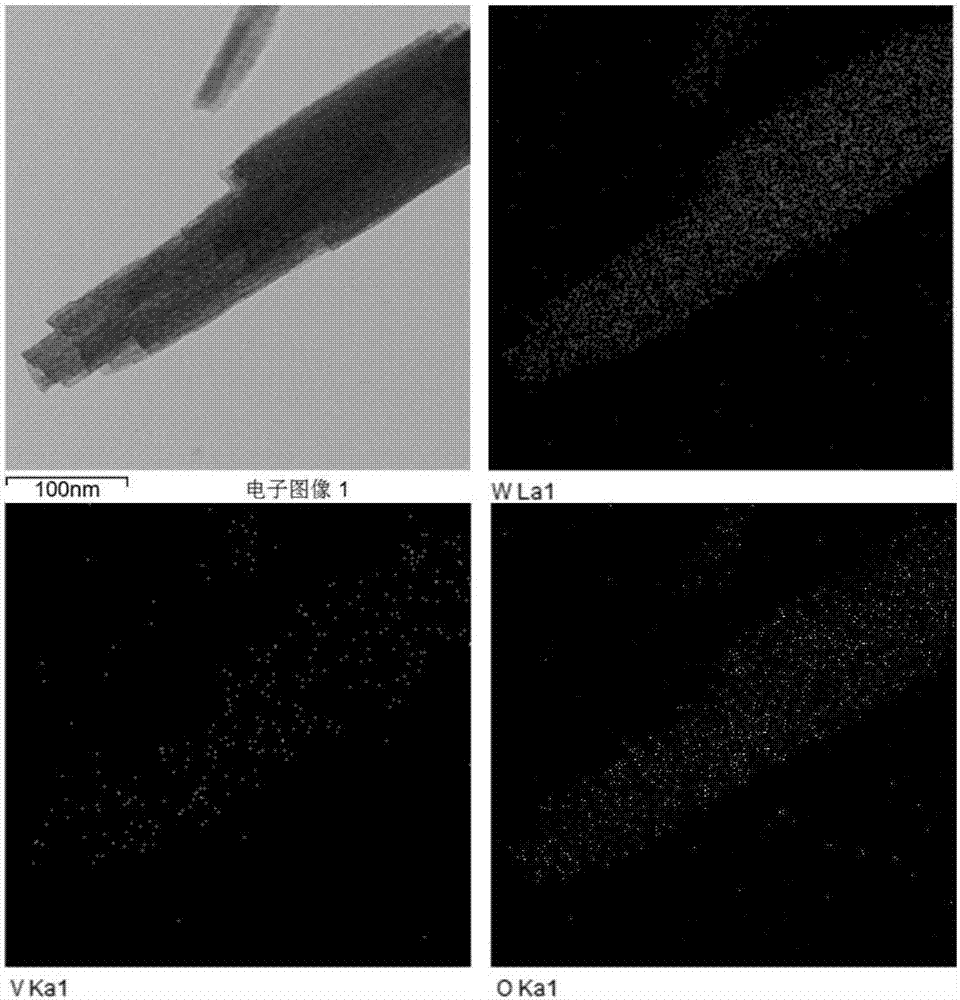

Embodiment 1

[0034] A preparation method of a tungsten trioxide / vanadium pentoxide core-shell nanowire array electrochromic material, the specific steps are as follows:

[0035] (1) Place the FTO conductive glass in a beaker filled with acetone, ethanol, and deionized water in turn, and ultrasonicate for 30 minutes respectively, and then put it on filter paper and dry it with an infrared lamp;

[0036] (2) Preparation of peroxytungstic acid solution: Dissolve 2.5g of tungstic acid in 60mL of deionized water by heating and stirring, then add 20mL of hydrogen peroxide with a mass fraction of 30% to it, stir until the solution is clear, and then dissolve it with deionized water Dilute the solution to a tungsten concentration of 0.05mol / L, and the diluted solution is peroxytungstic acid solution;

[0037] (3) Preparation of precursor solution: 10mL of peroxytungstic acid prepared in step (2), 10mL of deionized water and 40mL of acetonitrile were made into a mixed solution, and then the pH of t...

Embodiment 2

[0043] A preparation method of a tungsten trioxide / vanadium pentoxide core-shell nanowire array electrochromic material, the specific steps are as follows:

[0044] (1) Place the FTO conductive glass in a beaker filled with acetone, ethanol, and deionized water in turn, and ultrasonicate for 20 minutes respectively, and then put it on filter paper and dry it with an infrared lamp;

[0045] (2) Preparation of peroxytungstic acid solution: Dissolve 2.5g of tungstic acid in 60mL of deionized water by heating and stirring, then add 20mL of hydrogen peroxide with a mass fraction of 30% to it, stir until the solution is clear, and then dissolve it with deionized water Dilute the solution to a tungsten concentration of 0.05mol / L, and the diluted solution is peroxytungstic acid solution;

[0046] (3) Preparation of precursor solution: 10mL of peroxytungstic acid prepared in step (2), 40mL of acetonitrile, and 10mL of deionized water were made into a mixed solution, and then the pH of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com