Preparation method of bacterial-cellulose-based composite for flocculating decolorization of printing-dyeing wastewater

A technology for bacterial cellulose, printing and dyeing wastewater, applied in microorganism-based methods, biochemical equipment and methods, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of non-biodegradability and high production costs, and achieve efficient flocculation and decolorization , good flocculation decolorization effect, important application value and social benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

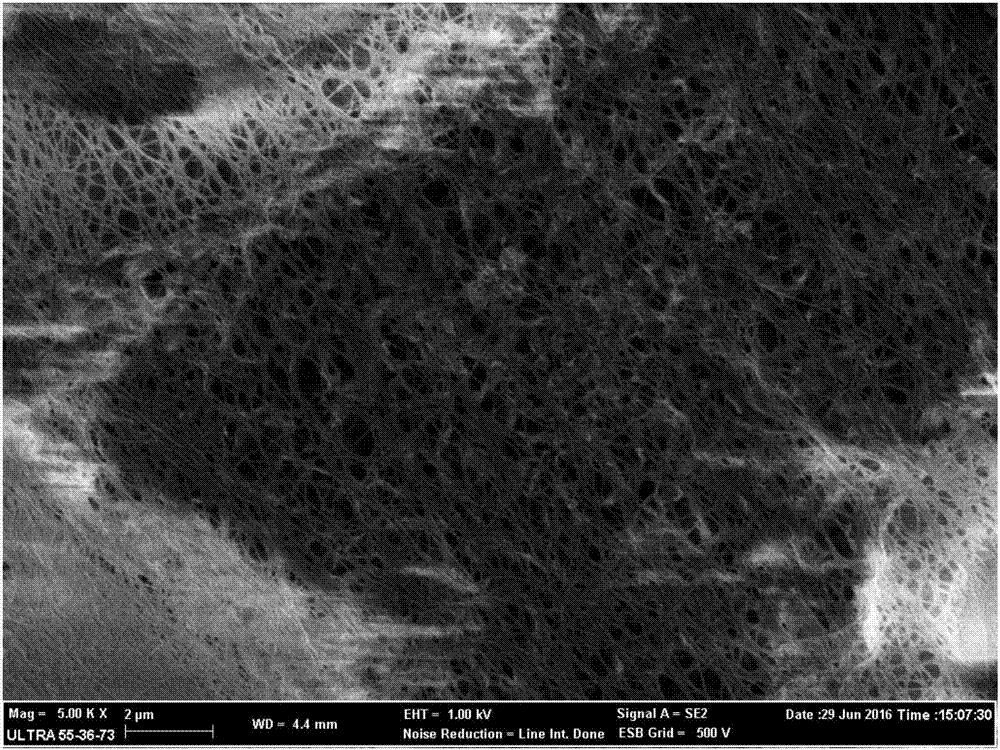

Image

Examples

Embodiment 1

[0019] 1) Under sterile conditions, use an inoculation loop to insert Gluconobacter (ATCC 49306) into 100mL liquid fermentation medium (35g / L glucose, 30g / L fructose, 3.0g / L yeast powder, 5.5g / L tryptone , 1.2g / L sodium citrate, pH 5, sterilized by high-temperature and high-pressure steam at 110°C for 30min), placed in a constant temperature shaker for shaking culture, culture temperature 29°C, rotation speed 80r / min, culture time 6d, a large number of flocculent Dispersed unpurified bacterial cellulose;

[0020] 2) Use 2 layers of gauze to filter out the culture medium from a large amount of flocculent dispersed unpurified bacterial cellulose obtained in step 1), soak it in a NaOH solution with a temperature of 70°C and a concentration of 0.1mol / L, and wash off the surface For the remaining bacterial protein and the medium components inside the cellulose, replace the NaOH solution every 20 minutes, and filter the purified bacterial cellulose after 3 cycles, then place it in 0...

Embodiment 2

[0023] 1) Under sterile conditions, use an inoculation loop to insert Gluconobacter (CGMCC 1671) into 100mL liquid fermentation medium (40g / L glucose, 35g / L fructose, 2.5g / L yeast powder, 5.0g / L tryptone , 0.8g / L sodium citrate, pH 4, sterilized by high-temperature and high-pressure steam at 110°C for 30min), placed in a constant temperature shaker for shaking culture, culture temperature 32°C, rotation speed 50r / min, culture time 9d, a large amount of flocculent Dispersed unpurified bacterial cellulose;

[0024] 2) Use 2 layers of gauze to filter out the culture medium from a large amount of flocculent dispersed unpurified bacterial cellulose obtained in step 1), soak it in a NaOH solution with a temperature of 90 ° C and a concentration of 0.1 mol / L, and wash off the residual cellulose on the surface. The bacterial protein and the medium components inside the cellulose were replaced with NaOH solution every 15 minutes, filtered to obtain the purified bacterial cellulose afte...

Embodiment 3

[0027] 1) Under sterile conditions, use an inoculation loop to insert Gluconobacter (ATCC 49306) into 100mL liquid fermentation medium (30g / L glucose, 40g / L fructose, 3.5g / L yeast powder, 4.5g / L tryptone , 1.0g / L sodium citrate, pH 6, sterilized by high temperature and high pressure steam at 110°C for 30min), placed in a constant temperature shaker for shaking culture, culture temperature 34°C, rotation speed 110r / min, culture time 8d, a large amount of flocculent Dispersed unpurified bacterial cellulose;

[0028]2) Use 2 layers of gauze to filter out the culture medium from a large amount of flocculent dispersed unpurified bacterial cellulose obtained in step 1), soak it in a NaOH solution with a temperature of 80°C and a concentration of 0.1mol / L, and wash off the residual cellulose on the surface. The bacterial protein and the medium components inside the cellulose were replaced with NaOH solution every 25 minutes, filtered to obtain the purified bacterial cellulose after 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com