Design and optimization method of a passive vibration controller for vibration control of flow pipes

A passive vibration and vibration control technology, used in design optimization/simulation, multi-objective optimization, computer-aided design, etc. And high-efficiency vibration control, reducing the difficulty of installation and use, the effect of simple controller structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

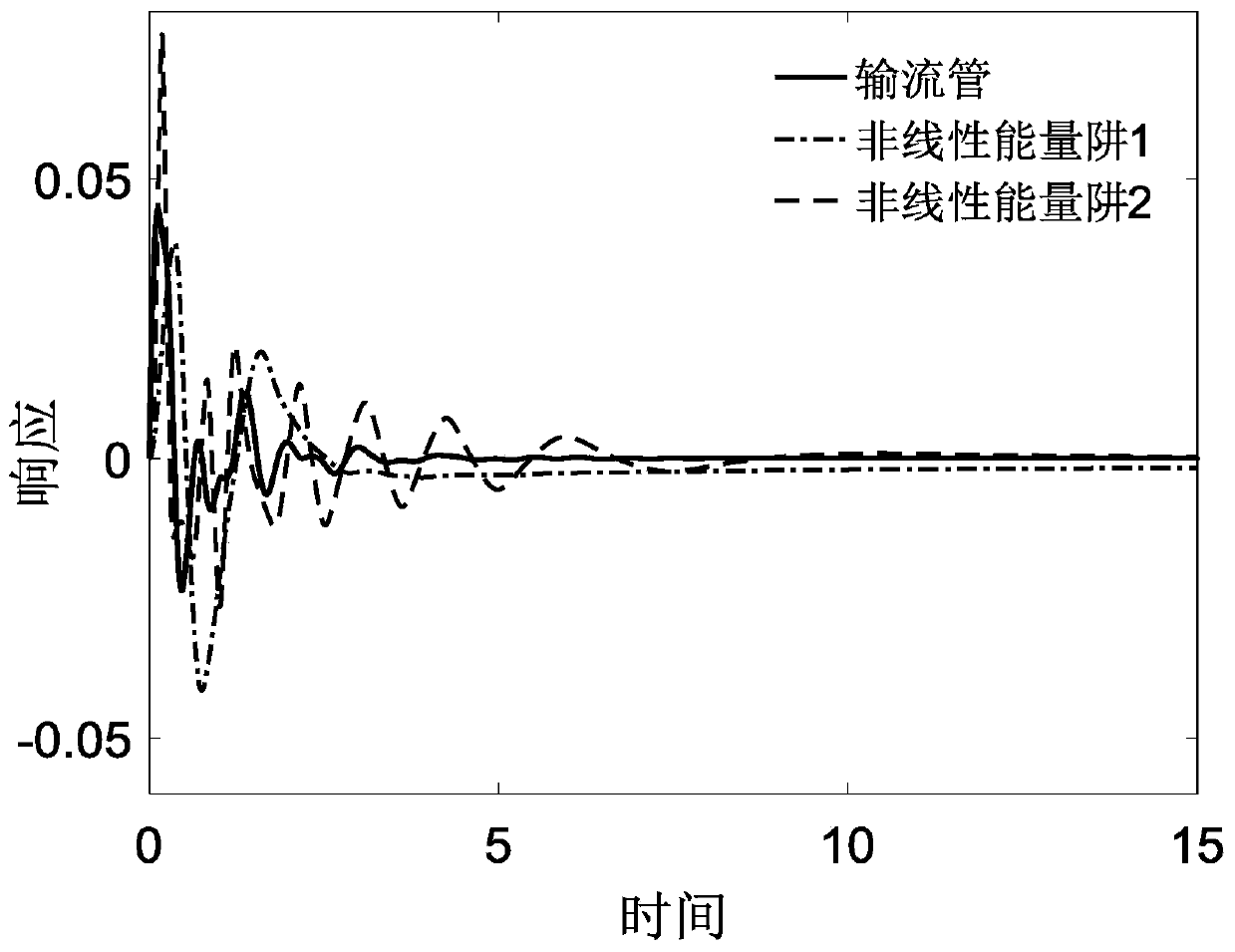

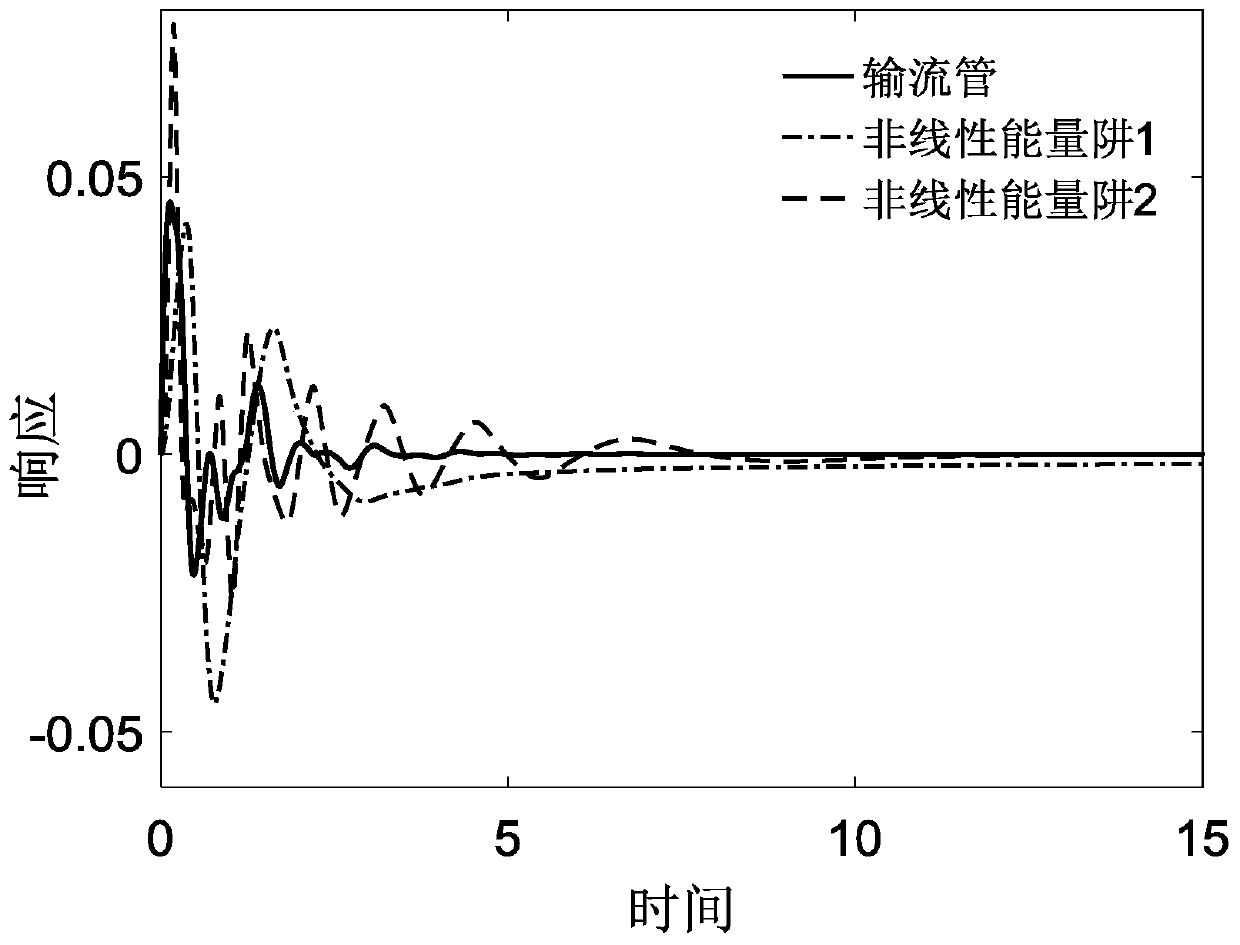

[0037]The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings and the simulation verification analysis process of the passive vibration controller.

[0038] The concrete case verification of the present invention is carried out at the emulation process of flow pipe---passive vibration controller system, detailed design steps are as follows:

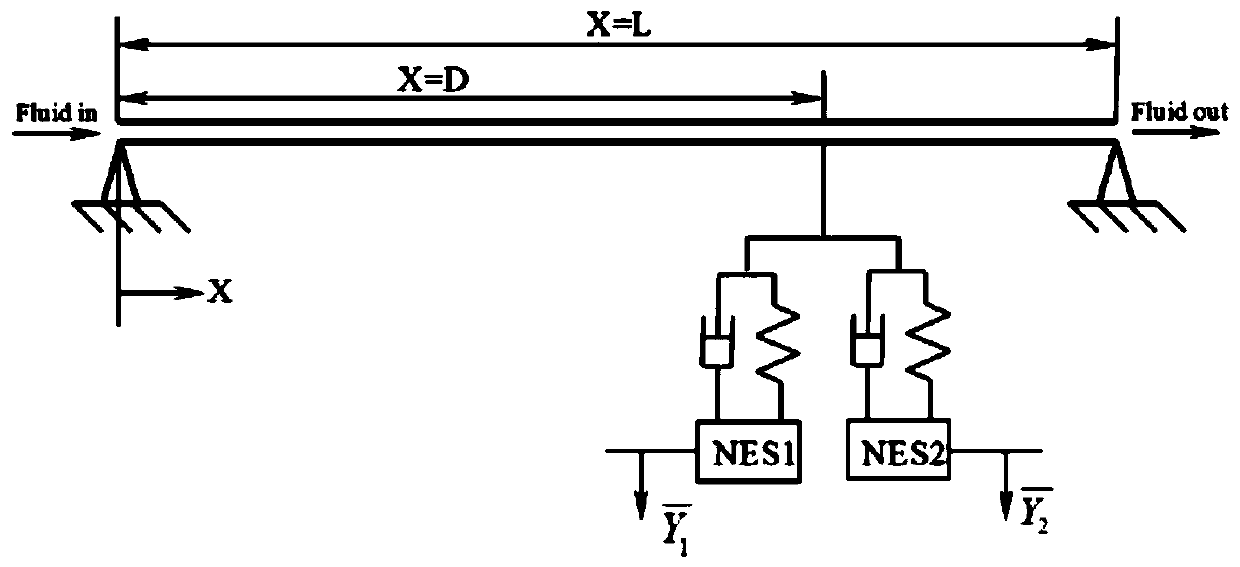

[0039] Step 1: Establish the mathematical model of the flow pipe-passive vibration controller, its physical structure is as follows figure 1 As shown, it is mainly composed of a flow pipe simply supported at both ends and a passive vibration controller connected to the pipe. The passive vibration controller is used to absorb the vibration energy generated when the fluid enters the pipeline. If gravity, internal damping, external tension and pressurization effects are not considered, the motion equation of the duct-passive vibration controller system can be written...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com