Metal-organic framework-phenolic resin composite material and method for preparing same

A metal-organic framework and phenolic resin technology, applied in the field of material chemistry, can solve the problem of no zeolite-like imidazole framework material and phenolic resin composite materials, and achieve the effect of enhancing hydrothermal stability and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

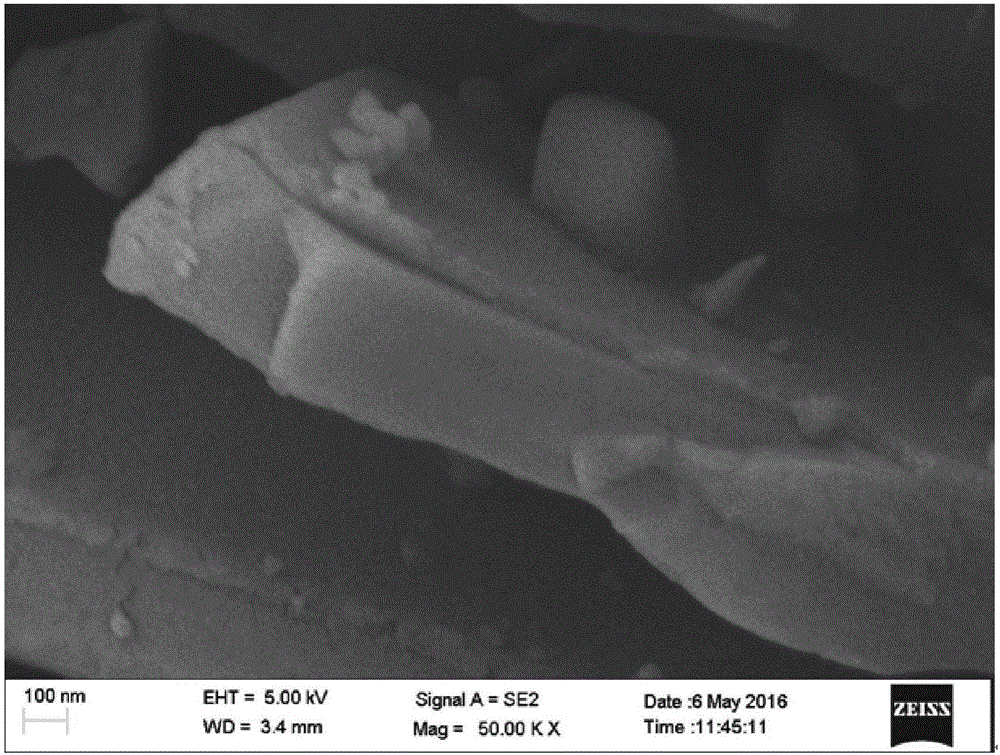

[0039] A method for preparing a metal-organic framework-phenolic resin composite material with a core-shell structure, comprising the steps of:

[0040] (1) 6g 2-methylimidazole is dissolved in the ammoniacal liquor of 90g 28wt.%, then it is added in the 75 grams of water that contains 12g zinc nitrate hexahydrate, stirs 2 hours under normal temperature, can obtain containing hyperdispersion ZIF-8 stock solution of crystal particles;

[0041] (2) In the stoste of step (1), continue to add the formaldehyde solution of 0.3 gram resorcinol and 0.7 gram, adjust pH value to be 3;

[0042](3) After the solution of step (2) was stirred at room temperature for 24 hours, it was transferred to a polytetrafluoroethylene-lined hydrothermal reactor, and heat-treated at 100°C for 24 hours, and the obtained product was filtered, washed and dried. Obtain a ZIF-8 composite material with a core-shell structure in which the metal-organic framework material is the core and the phenolic resin is ...

Embodiment 2

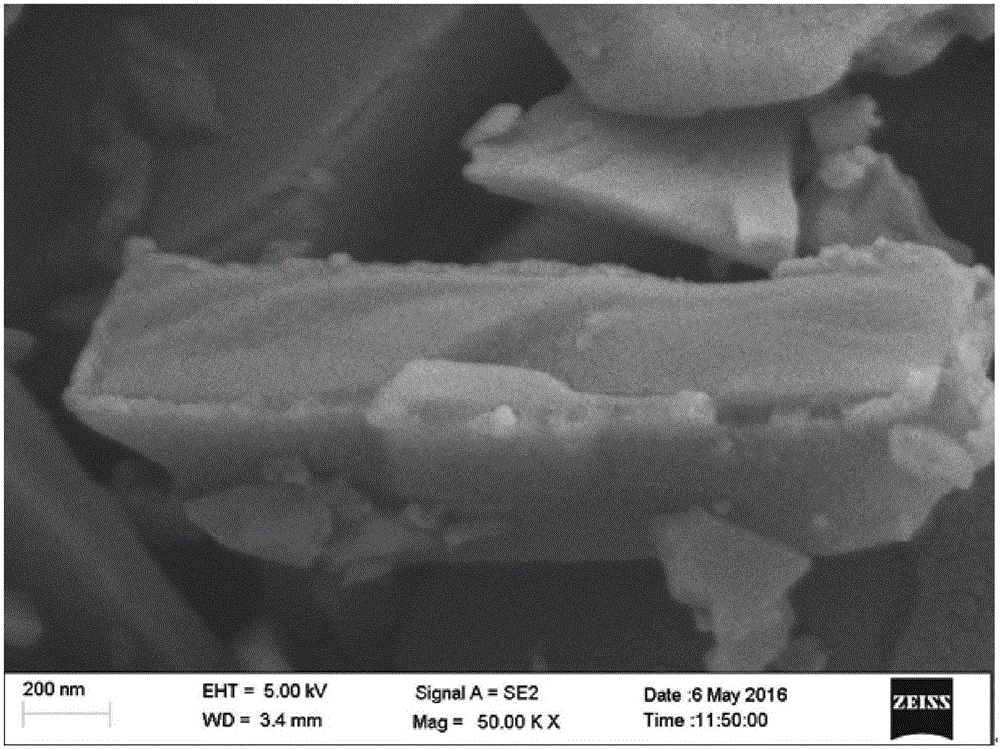

[0046] A method for preparing a metal-organic framework-phenolic resin composite material with a core-shell structure, comprising the steps of:

[0047] (1) 6g 2-methylimidazole is dissolved in the ammoniacal liquor of 90g 28wt.%, then it is added in the 75 grams of water that contains 12g zinc nitrate hexahydrate, stirs 2 hours under normal temperature, can obtain containing hyperdispersion ZIF-8 stock solution of crystal particles;

[0048] (2) In the stoste of step (1), continue to add the acetaldehyde solution of 0.6 gram of phenol and 0.6 gram, adjust pH value to be 7;

[0049] (3) After the solution of step (2) was stirred at room temperature for 36 hours, it was transferred to a polytetrafluoroethylene-lined hydrothermal reactor, and heat-treated at 200° C. for 3 hours, and the obtained product was filtered, washed, and dried. A ZIF-8 composite material with a core-shell structure in which metal-organic framework material is the core and phenolic resin is the shell is ...

Embodiment 3

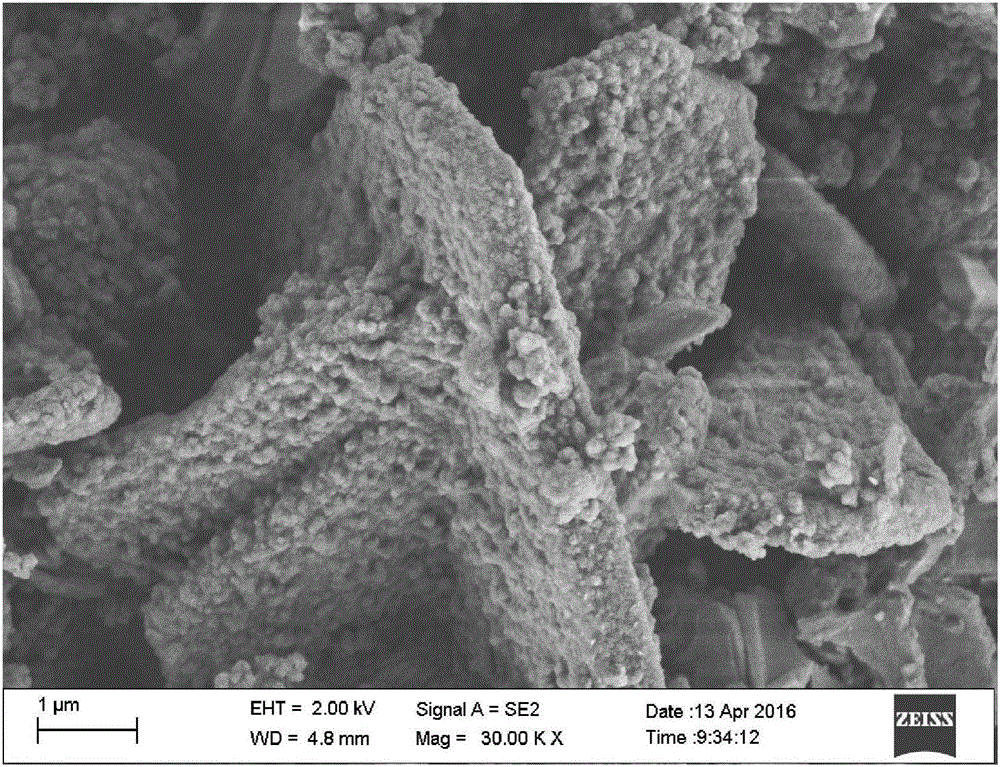

[0051] A method for preparing a metal-organic framework-phenolic resin composite material with a core-shell structure, comprising the steps of:

[0052] (1) 6g 2-methylimidazole is dissolved in the ammoniacal liquor of 90g 28wt.%, then it is added in the 75 grams of water that contains 12g zinc nitrate hexahydrate, stirs 2 hours under normal temperature, can obtain containing hyperdispersion ZIF-8 stock solution of crystal particles;

[0053] (2) In the stock solution of step (1), continue to add 1.2 grams of pyroglucinol and 2.1 grams of phthalaldehyde solution, and adjust the pH value to 12;

[0054] (3) After the solution of step (2) was stirred at room temperature for 24 hours, it was transferred to a polytetrafluoroethylene-lined hydrothermal reactor, and heat-treated at 100°C for 24 hours, and the obtained product was filtered, washed and dried. A ZIF-8 composite material with a core-shell structure in which metal-organic framework material is the core and phenolic resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com