Special waste rubber composite modifier for waterproof roll roofing and preparation method of special waste rubber composite modifier

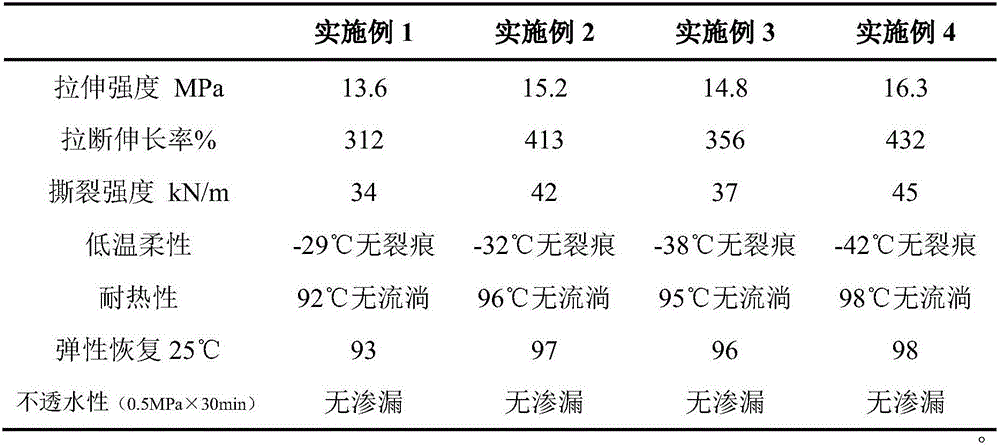

A composite modifier and waterproof membrane technology, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of weak radiation and corrosion, poor viscosity, etc., and achieve improved physical properties, improved adhesion, and wear resistance homogeneous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

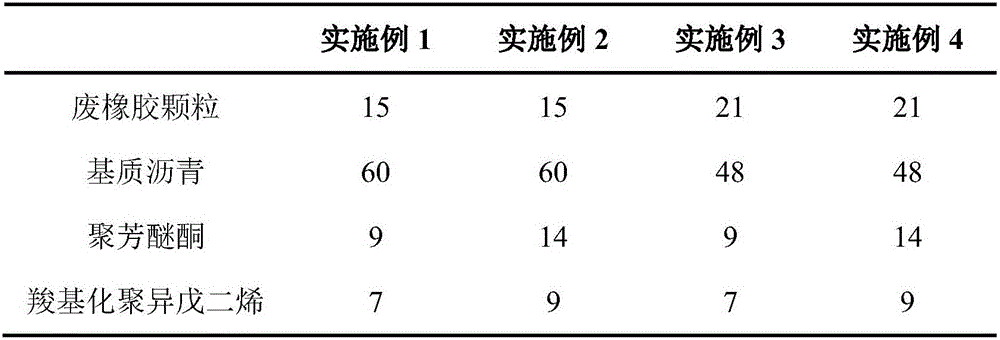

[0024] A special waste rubber compound modifier for waterproof coiled materials, characterized in that it is composed of the following raw material components in the following weight ratio: 13-22% of waste rubber particles, 8-16% of polyaryletherketone, carboxylated polyisoamyl Diene 6-10%, matrix pitch 40-63%.

[0025] The particle size of waste rubber particles is 3-5mm, and the base asphalt is 30# or 45# petroleum asphalt.

[0026] A kind of preparation method of waste rubber composite modifier special for waterproof coiled material, it is characterized in that: comprise the following steps:

[0027] (1) Put the waste rubber granules recovered from waste tires into the reactor and feed them with supercritical CO 2 Make it maintain a certain pressure and fully stir and preheat at a certain temperature, and then add it to the co-rotating full-meshing twin-screw extruder with a three-stage thread structure, which is sequentially transported by the screw to compact the materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com