Biological gas production system for filling straws in mine goaf and gas production process thereof

A technology of straw biology and goaf, which is applied in the engineering field of combining biotransformation to achieve the effect of slowing down land subsidence and slowing down surface subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

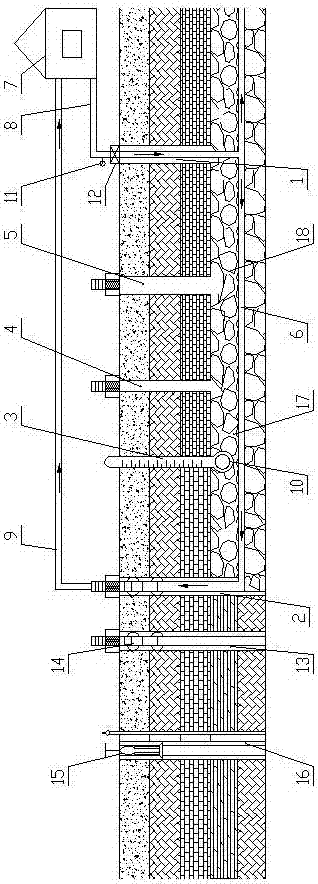

[0023] Such as figure 1 As shown, a mine goaf filling straw biological gas production system of the present invention includes a hot water inlet well 1 connected to the ground above the mine goaf 17, a return well 2, a temperature monitoring well 3, an external source Bacteria injection and flora monitoring wells 4 and biogas gathering and transportation wells 5 are laid criss-cross on the ground in the goaf 17. Insulation pipelines 6 made of stainless steel or aluminum alloy materials (to reduce corrosion) are laid. Radiating fins are evenly arranged on the top, the distance between the hot water entering well 1 and the thermal power plant 7 is smaller than the distance between the return water well 2 and the thermal power plant 7, and the waste water discharge pipe 8 of the thermal power plant 7 passes through the hot water entering well 1 and extends to the mining area. The empty area 17 is connected with the water inlet of the thermal insulation pipeline 6, and the water o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com