Ultra-fine grain martensite ferrite dual-phase steel with two-peak ferrite grains distributed and production process of ultra-fine grain martensite ferrite dual-phase steel

A production process and ferrite technology, applied in the field of metallurgical materials, can solve the problems of low uniform elongation and achieve the effect of improving uniform elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

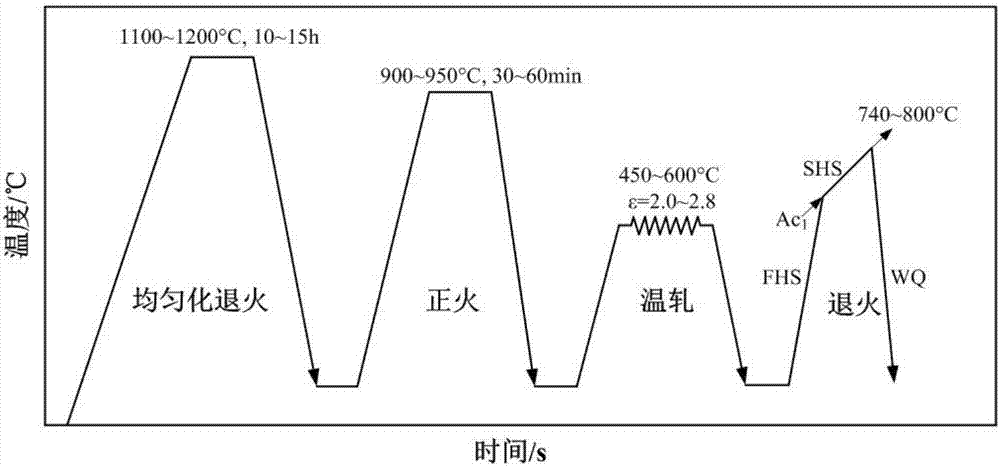

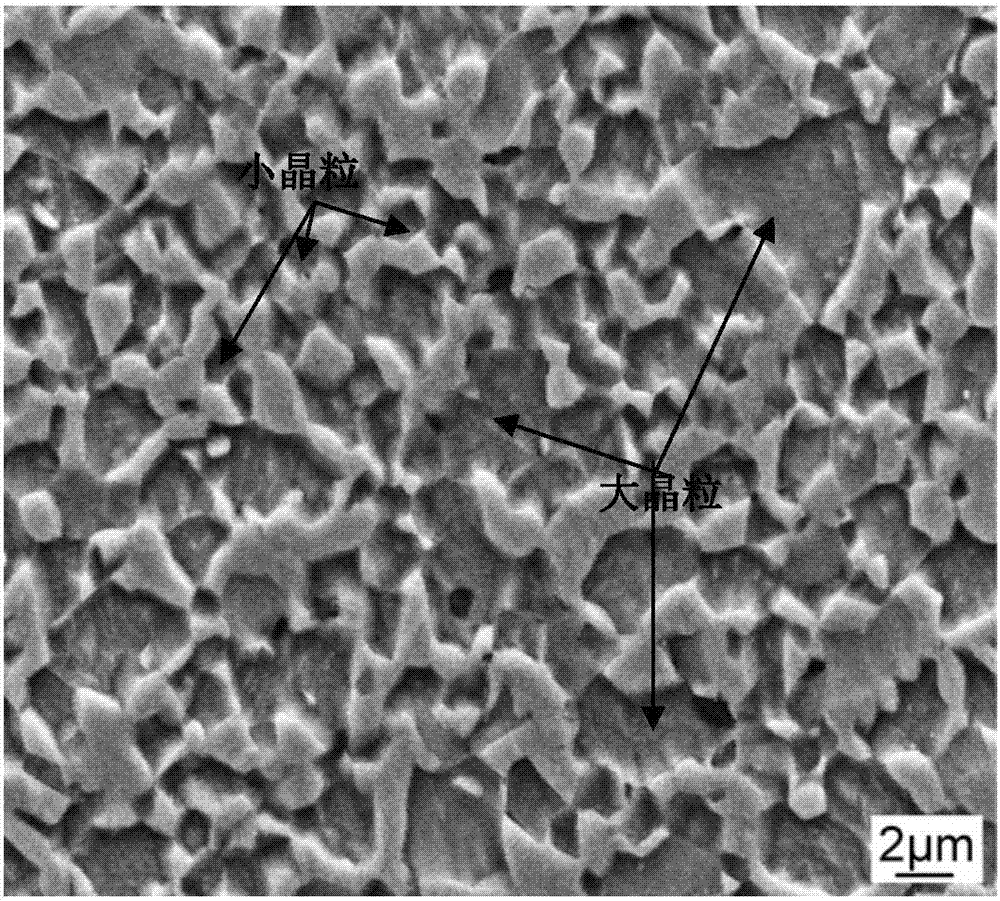

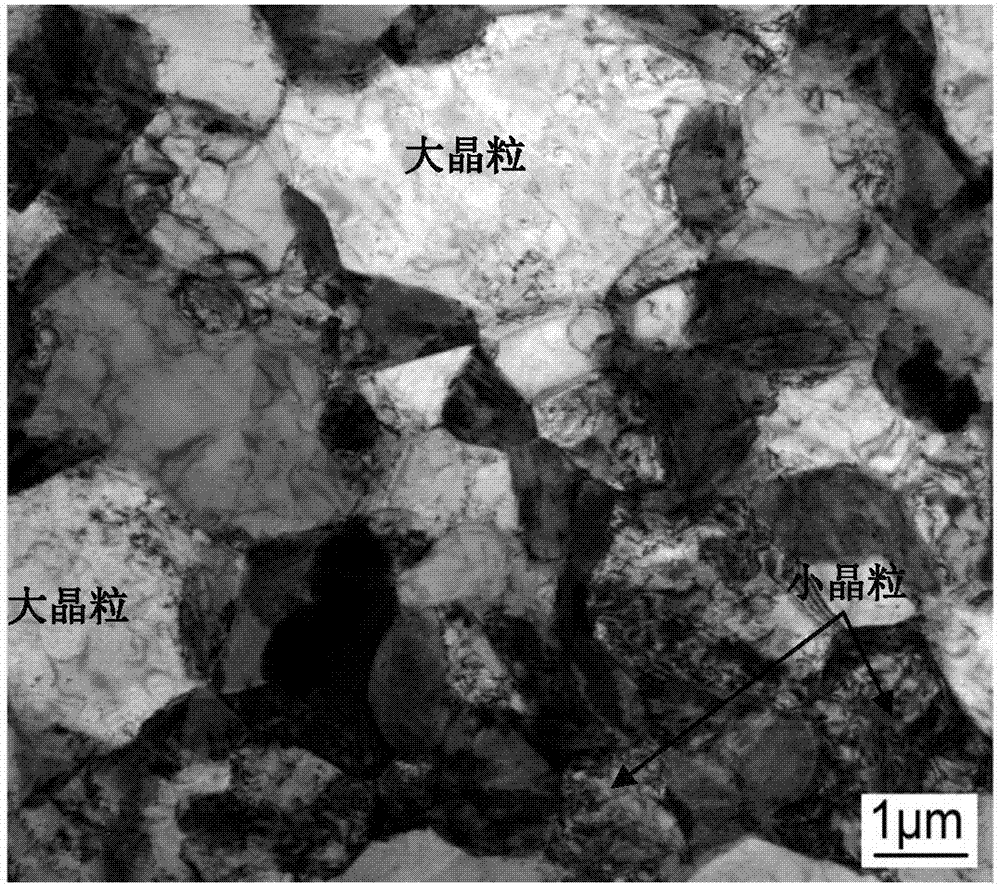

[0046] The selected ingot composition weight percent is: C 0.11%, Mn 1.83%, Si 0.062%, Al 0.38%, Mo0.17%, Cr 0.37%, Nb 0.04%, and the balance is Fe. The final rolling temperature is 800°C, and the strip thickness after rolling is 4.3mm. The hot-rolled slab was annealed at 1100°C for 10 hours, then cooled to room temperature in the furnace, then normalized at 900°C for 30 minutes, reheated to 570°C and kept for 10 minutes for warm rolling, and air-cooled to room temperature. The thickness of the obtained slab was 0.35 mm (ε=2.5 ); the warm-rolled slab is annealed on a continuous annealing test machine, the first heating (FHS) rate is 40 ° C / s, heated to Ac 1 Temperature (655°C), the second stage heating (SHS) rate is 2°C / s, and it is quenched immediately after heating to 750°C. The finally obtained ultra-fine-grained dual-phase steel sheet with bimodal ferrite distribution, the fine-grained ferrite grain size is 0.5-3 μm, and the coarse-grained ferrite grain size is 3-6.5 μm...

Embodiment 2

[0048] The selected ingot composition weight percent is: C 0.10%, Mn 1.7%, Si 0.05%, Al 0.35%, Mo0.16%, Cr 0.35%, Nb 0.037%, and the balance is Fe. The final rolling temperature is 820°C, and the strip thickness after rolling is 4mm. The hot-rolled slab was annealed at 1150°C for 12 hours, then furnace-cooled to room temperature, then normalized at 930°C for 30 minutes, reheated to 550°C and kept for 10 minutes for warm rolling, and air-cooled to room temperature. The thickness of the obtained slab was 0.4 mm (ε = 2.3); the warm-rolled slab is annealed on a continuous annealing test machine, the first heating (FHS) rate is 60 ° C / s, heated to Ac 1 temperature (663°C), the second stage heating (SHS) rate is 3°C / s, and it is quenched immediately after heating to 760°C. The final ultra-fine-grained dual-phase steel plate with bimodal ferrite distribution was obtained. The grain size of the fine-grained part of ferrite was 0.5-3 μm, and the grain size of the coarse-grained ferr...

Embodiment 3

[0050] The selected ingot composition weight percent is: C 0.08%, Mn 1.80%, Si 0.06%, Al 0.36%, Mo 0.16%, 0.38% Cr, 0.039% Nb, and the balance is Fe. The final rolling temperature is 850°C, and the strip thickness after rolling is 4.2mm. The hot-rolled slab was annealed at 1180°C for 15 hours, then furnace-cooled to room temperature, then normalized at 950°C for 20 minutes, reheated to 500°C and kept for 10 minutes for warm rolling, and air-cooled to room temperature. The thickness of the obtained slab was 0.45 mm (ε = 2.2); the warm-rolled slab is annealed on a continuous annealing test machine, the first heating (FHS) rate is 80 ° C / s, heated to Ac 1 Temperature (678°C), the second stage heating (SHS) rate is 4°C / s, and it is quenched immediately after heating to 770°C. The final ultra-fine-grained dual-phase steel sheet with bimodal ferrite distribution, the fine-grained ferrite grain size measured by scanning electron microscopy is 0.5-3 μm, and the coarse-grained ferri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com