Cleaning agent for aluminum fin and cleaning method

A cleaning agent and aluminum fin technology, applied in the field of cleaning agents, can solve the problems of unsightly appearance, dull aluminum profile surface, weak corrosion resistance, etc., and achieve the effects of easy transportation, good water solubility and permeability, and corrosion prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A cleaning agent for aluminum fins, comprising the following raw materials in parts by weight:

[0031] 18 parts of sodium aluminate, 45 parts of sodium chloride, 5 parts of triethanolamine, 12 parts of slime remover, 1 part of butyl acrylate copolymer, and 60 parts of water.

[0032] Preferably, the slime stripping agent includes 1.5 parts of sodium hypochlorite, 4.5 parts of benzalkonium bromide, 3 parts of dodecyl dimethyl benzyl ammonium chloride, 1 part of sodium alkylbenzene sulfonate and dibasic phthalic acid 2 parts lead.

[0033] According to the above formula, each component is accurately weighed, mixed uniformly, inspected and packaged to obtain the aluminum fin cleaning agent of the present invention.

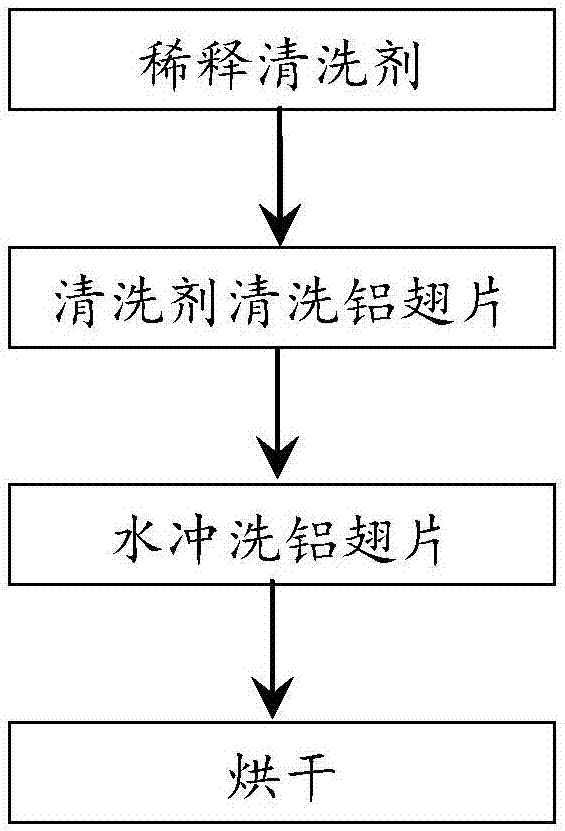

[0034] A cleaning method for aluminum fins, such as figure 1 As mentioned above, using the above-mentioned cleaning agent to clean the aluminum fins includes the following steps:

[0035] (1) Dilute cleaning agent: add water to the above-mentioned cleaning...

Embodiment 2

[0040] A cleaning agent for aluminum fins, comprising the following raw materials in parts by weight:

[0041] 28 parts of aluminum tartrate, 15 parts of sodium fluoride, 15 parts of cobalt naphthenate, 5 parts of slime remover, 5 parts of methyl methacrylate and butyl acrylate copolymer, 30 parts of water.

[0042] Preferably, the slime stripping agent includes 0.5 part of sodium hypochlorite, 2 parts of benzalkonium bromide, 1 part of dodecyldimethylbenzyl ammonium chloride, 0.5 part of sodium alkylbenzenesulfonate and dibasic phthalic acid 1 part of lead.

[0043] According to the above formula, each component is accurately weighed, mixed uniformly, inspected and packaged to obtain the aluminum fin cleaning agent of the present invention.

[0044] A cleaning method for aluminum fins, such as figure 1 As mentioned above, using the above-mentioned cleaning agent to clean the aluminum fins includes the following steps:

[0045] (1) Dilute cleaning agent: add water to the ab...

Embodiment 3

[0050] A cleaning agent for aluminum fins, comprising the following raw materials in parts by weight:

[0051]23 parts of aluminum chlorate, 30 parts of sodium bicarbonate, 10 parts of triethylenediamine, 8.5 parts of slime stripping agent, 3 parts of polyether modified polysiloxane, 45 parts of water.

[0052] Preferably, the slime stripping agent includes 1 part of sodium hypochlorite, 3.25 parts of benzalkonium bromide, 2 parts of dodecyl dimethyl benzyl ammonium chloride, 0.75 part of sodium alkylbenzene sulfonate and dibasic phthalic acid 1.5 parts of lead.

[0053] According to the above formula, each component is accurately weighed, mixed uniformly, inspected and packaged to obtain the aluminum fin cleaning agent of the present invention.

[0054] A cleaning method for aluminum fins, such as figure 1 As mentioned above, using the above-mentioned cleaning agent to clean the aluminum fins includes the following steps:

[0055] (1) Dilute cleaning agent: add water to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com