Robot and robot vision training platform

A technology of robot vision and practical training platform, applied in the field of robotics, can solve the problems of single work in intelligent assembly line and inability to do diversified work, and achieve the effect of reducing energy loss, reducing production cost and safe working effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

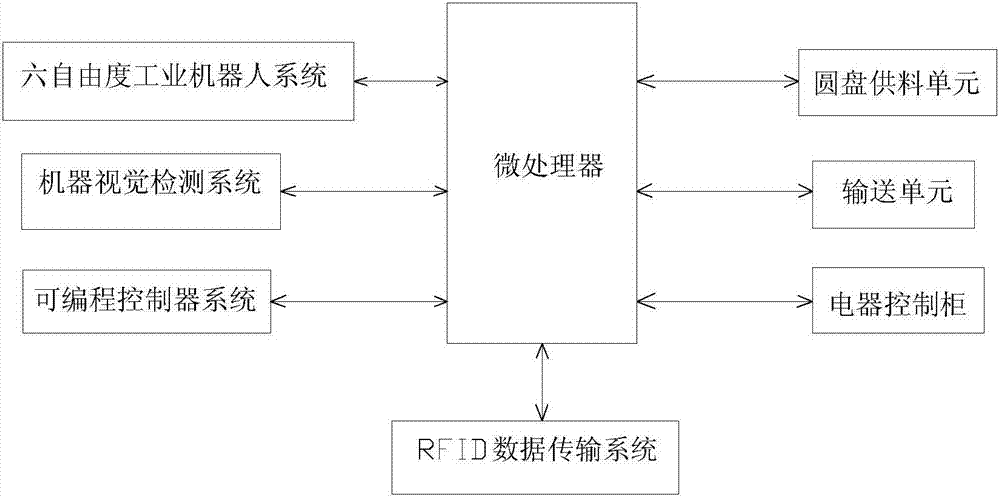

[0016] A robot and robot vision training platform, including a six-degree-of-freedom industrial robot system, a machine vision inspection system, a programmable controller system, an RFID data transmission system, a disc feeding unit, a conveying unit, a workpiece assembly unit, and an electrical control cabinet , microprocessor; the six-degree-of-freedom industrial robot system consists of a robot body, a robot controller, a teaching unit, an input-output signal converter, and a grasping mechanism. The six-degree-of-freedom industrial robot system is equipped with a variety of fixtures, suction cups, measuring tools, Tool, which can grasp, absorb, transport, assemble, polish, measure, and disassemble the workpiece. Generally speaking, the robot body is composed of six-degree-of-freedom joints, fixed on the profile training table, and the radius of the range of motion is greater than 700mm. Less than 340°, the teaching unit is equipped with LCD screen, enable button, emergency ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com