Device and method for separating sucralose exhaust

A sucralose, tail gas technology, applied in chemical instruments and methods, carboxylic acid amide separation/purification, specific gas purification/separation, etc., can solve the problem of DMF, trichloroethane solvent, liquid alkali consumption and Problems such as high operating cost and easy environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

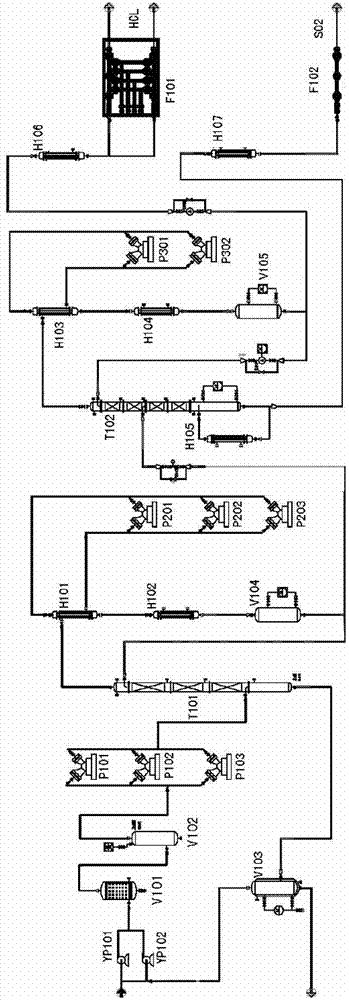

[0027] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0028] A method for separating sucralose tail gas mentioned in the present invention comprises the following steps:

[0029] 1) The mixed tail gas after chlorination of sucralose production (containing SO2 60.52%, HCl 36.31%, trichloroethane 0.99%, DMF 0.25%, air 1.93%, temperature 12 ℃), the flow rate is about 2000kg / h, by The pipeline is transported to liquid ring pump P101 and liquid ring pump P102. The liquid ring pump uses 98% concentrated sulfuric acid medium to absorb trace moisture and pressurize the mixed airflow to 1bar (gauge pressure, 1bar=100kPa) before entering the demister tank V101. After removing the concentrated sulfuric acid mist, it enters the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com