Method for treating medium- and low-grade bauxite to produce metallurgical-level aluminum oxide by one-step andradite alkali heat method

A low-grade bauxite and andandrite technology, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve problems that hinder the normal operation of the production process, achieve improved dissolution rate, high efficiency, and improved dissolution rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment adopts middle and low-grade bauxite, and its main chemical composition (mass percentage, wt%) is: alumina (Al 2 o 3 )60.60%, silicon dioxide (SiO 2 ) 17.5%, the others are impurities, and its aluminum-silicon ratio is 3.5;

[0041] Calcium ferrite is sintered from iron-containing raw materials and lime;

[0042] The caustic alkali concentration in the circulating mother liquor is 200g / L, and the molecular ratio is 25;

[0043] F / A=0.5:1;

[0044] C / F=4.5:1.

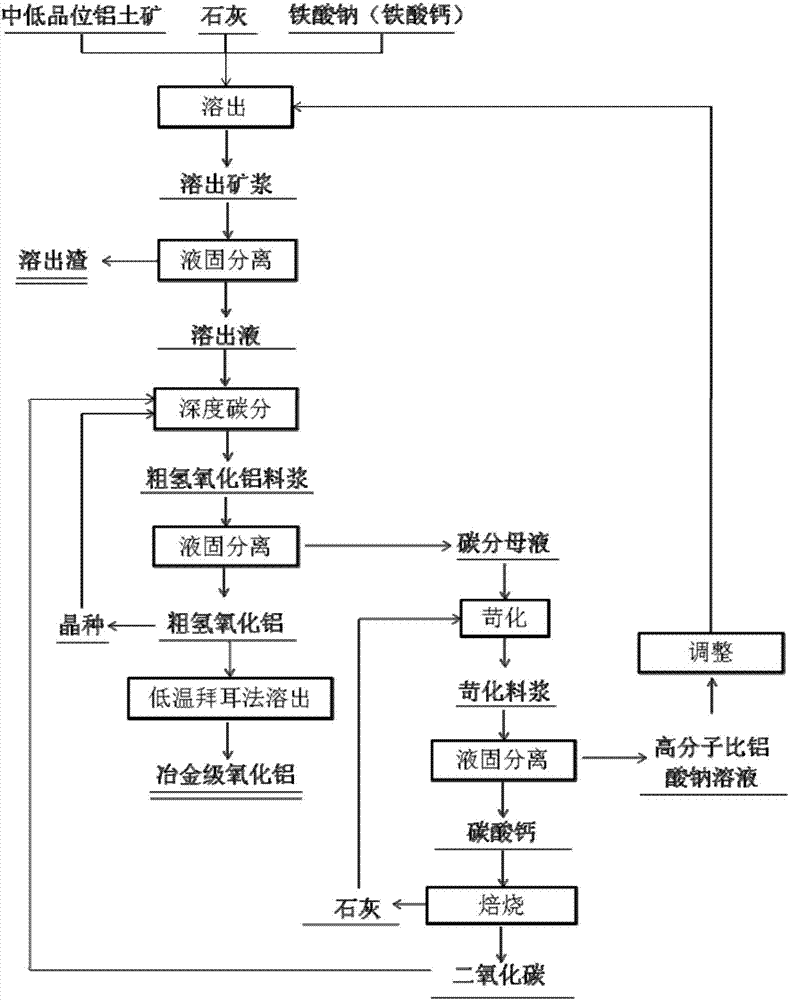

[0045] according to this figure 1 The method for the production of metallurgical grade alumina of the present invention in one-step alkali-thermal treatment of andradite bauxite with medium and low grades:

[0046] S1: Crushing and grinding medium and low-grade bauxite into ore powder;

[0047] S2: After mixing mineral powder, calcium ferrite and active lime, mix them with circulating mother liquor according to the ratio of L / S=4:1 to prepare raw material slurry;

[0048] S3: The raw materia...

Embodiment 2

[0063] This embodiment adopts middle and low-grade bauxite, and its main chemical composition (mass percentage, wt%) is: alumina (Al 2 o 3 )65.22%, silicon dioxide (SiO 2 ) 12.66%, the others are impurities, and its aluminum-silicon ratio is 5.15;

[0064] Sodium ferrite is sintered from iron-containing raw materials and industrial carbon soda;

[0065] The caustic alkali concentration in the circulating mother liquor is 230g / L, and the molecular ratio is 20.

[0066] F / A=0.6:1;

[0067] C / F=4:1.

[0068] according to this figure 1 The method for the production of metallurgical grade alumina of the present invention in one-step alkali-thermal treatment of andradite bauxite with medium and low grades:

[0069] S1: Crushing and grinding medium and low-grade bauxite into ore powder;

[0070] S2: After mixing mineral powder, sodium ferrite and active lime, mix it with circulating mother liquor according to the ratio of L / S=4:1 to prepare raw material slurry;

[0071] S3: C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com