Phosphogypsum crushing and drying powder production line

A phosphogypsum and production line technology, which is applied in the field of phosphogypsum crushing and drying powder production line, can solve the problems of continuous and stable operation of the production line, high equipment operation cost, and rising machine failure rate, so as to reduce processing costs, energy consumption, and use costs Low, the effect of improving the dredging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

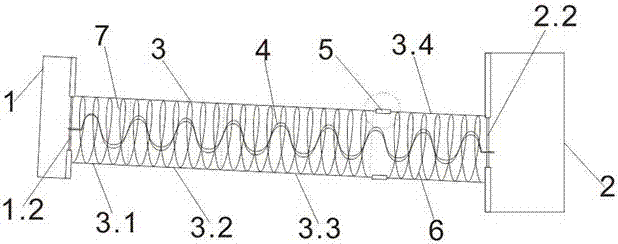

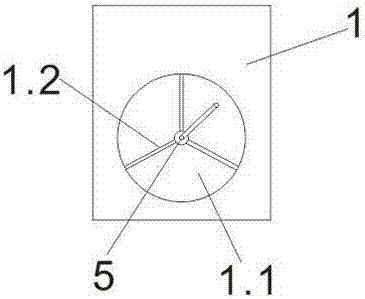

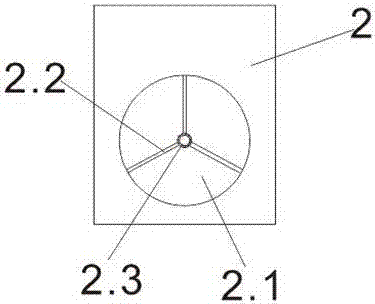

[0040] Such as figure 1and Figure 7 As shown, the phosphogypsum crushing and drying powder production line includes a rotary kiln 3, a crusher, a frying furnace and a ball mill. The finished gypsum powder is obtained by kiln calcination and ball mill grinding. The rotary kiln 3 is installed between the kiln head cover 1 and the kiln tail smoke chamber 2. Tropical zone 3.1, transition zone 3.2, firing zone 3.3 and cooling zone 3.4.

[0041] As an improvement, such as figure 1 As shown, the rotary kiln 3 is set as a high-temperature rotary kiln for anti-blocking material phosphogypsum. The inner walls of the preheating zone 3.1, the transition zone 3.2 and the firing zone 3.3 of the anti-blocking material phosphogypsum high-temperature r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com