A coating for the inner wall of the centrifugal drum of a centrifuge

An in-drum, centrifuge technology, applied in the field of centrifuges, can solve the problems of limited corrosion resistance and friction resistance, long contact time of the inner wall of the centrifugal drum, and large friction and impact force, and achieves excellent corrosion resistance and chemical resistance. performance, good chemical inertness, low coefficient of friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

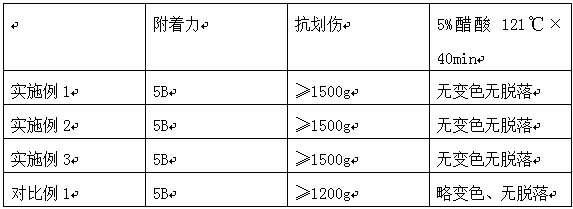

Embodiment 1

[0014] A paint for the inner wall of a centrifugal drum of a centrifuge, including organic solvents, auxiliary components, and the following components in parts by weight: epoxy resin 1009 18-42, blocked isocyanate 3175 3-8, fluorocarbon emulsion 10-20, nano Sericite composite particles 0.4-0.6.

[0015] The epoxy equivalent of the epoxy resin 1009 is 2100-2200g / eq.

[0016] The unblocking temperature of the blocked isocyanate 3175 is ≤165°C.

[0017] The organic solvent is one or a combination of n-butanol and propylene glycol methyl ether, and the added weight of the organic solvent is 40-80.

[0018] The auxiliary agent is a film-forming auxiliary agent, and the film-forming auxiliary agent is dodecyl alcohol ester, and the added weight part of the auxiliary agent is 0.5-0.8.

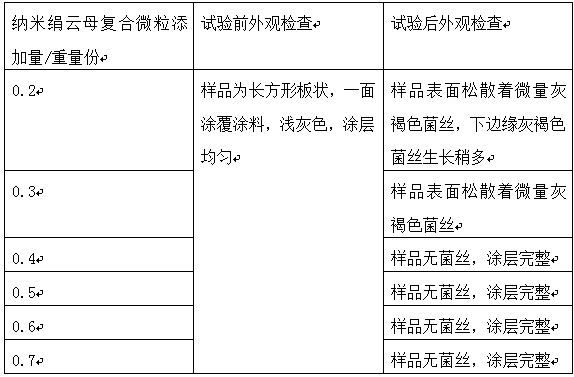

[0019] The preparation method of the nano-sericite composite particles is as follows: a certain amount of nano-sericite is mixed with water to prepare a nano-sericite aqueous suspension with a mass...

Embodiment 2

[0022] A paint for the inner wall of a centrifugal drum of a centrifuge, including organic solvents, auxiliary components, and the following components in parts by weight: epoxy resin 1009 18-42, blocked isocyanate 3175 3-8, fluorocarbon emulsion 10-20, nano Sericite composite particles 0.4-0.6.

[0023] The epoxy equivalent of the epoxy resin 1009 is 2100-2200g / eq.

[0024] The unblocking temperature of the blocked isocyanate 3175 is ≤165°C.

[0025] The organic solvent is one or a combination of n-butanol and propylene glycol methyl ether, and the added weight of the organic solvent is 40-80.

[0026] The auxiliary agent is a film-forming auxiliary agent, and the film-forming auxiliary agent is dodecyl alcohol ester, and the added weight part of the auxiliary agent is 0.5-0.8.

[0027] The preparation method of the nano-sericite composite particles is as follows: a certain amount of nano-sericite is mixed with water to prepare a nano-sericite aqueous suspension with a mass...

Embodiment 3

[0030] A paint for the inner wall of a centrifugal drum of a centrifuge, including organic solvents, auxiliary components, and the following components in parts by weight: epoxy resin 1009 18-42, blocked isocyanate 3175 3-8, fluorocarbon emulsion 10-20, nano Sericite composite particles 0.4-0.6.

[0031] The epoxy equivalent of the epoxy resin 1009 is 2100-2200g / eq.

[0032] The unblocking temperature of the blocked isocyanate 3175 is ≤165°C.

[0033] The organic solvent is one or a combination of n-butanol and propylene glycol methyl ether, and the added weight of the organic solvent is 40-80.

[0034] The auxiliary agent is a film-forming auxiliary agent, and the film-forming auxiliary agent is dodecyl alcohol ester, and the added weight part of the auxiliary agent is 0.5-0.8.

[0035] The preparation method of the nano-sericite composite particles is as follows: a certain amount of nano-sericite is mixed with water to prepare a nano-sericite aqueous suspension with a mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com