Zinc hydrometallurgy novel efficient purification process

A purification process, zinc hydrometallurgy technology, applied in the direction of photographic process, photographic auxiliary process, process efficiency improvement, etc., can solve the difficulty of purification and separation of impurity ions such as copper, cadmium and cobalt in the main and auxiliary systems, and the recovery rate of valence metals is not high , Incomplete removal of impurities, etc., to avoid the risk of electrolytic burning, short reaction time, and strong purification and removal capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

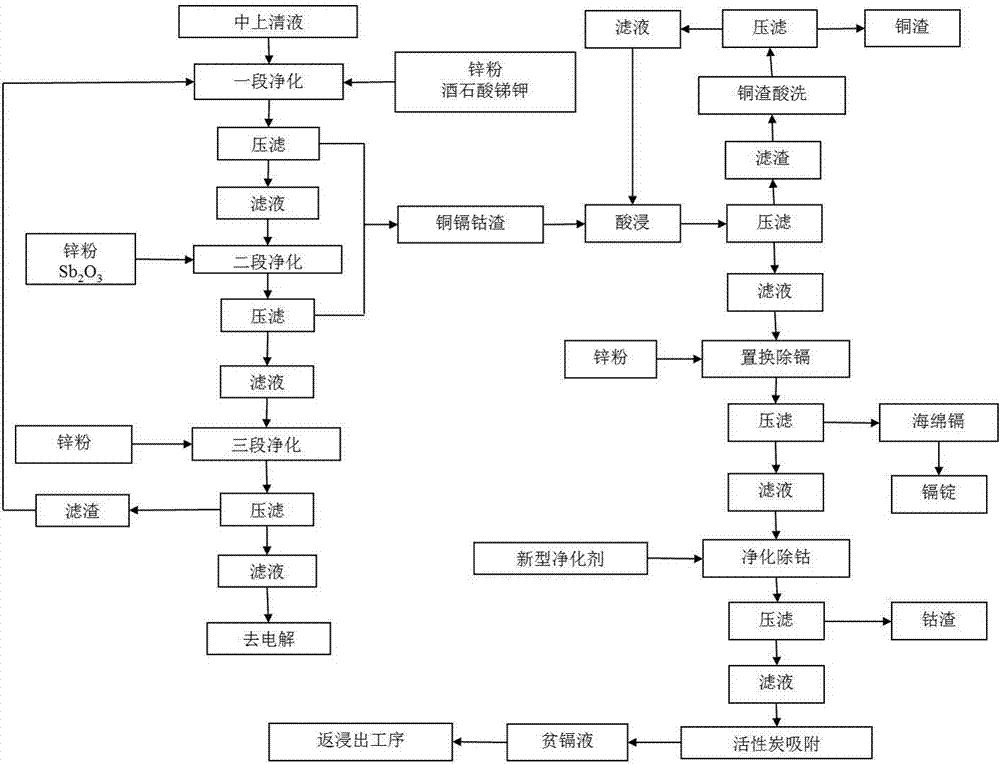

[0011] Such as figure 1 The new high-efficiency purification process of zinc hydrosmelting shown is characterized in that it includes a main system purification process and a secondary system purification process, and belongs to the technical field of hydro-smelting zinc liquid purification production. In the new high-efficiency purification process of zinc hydrometallurgy, the main system adopts the zinc powder replacement method to remove copper, cadmium and cobalt and other impurity ions from the zinc liquid, and the secondary system adopts the zinc powder replacement + chemical agent method to separate and purify the copper, cadmium and cobalt slag. The new purification process of zinc hydrometallurgy includes: (1) three-stage purification of the main system to remove copper, cadmium, cobalt and other impurity ions from the zinc liquid; (2) four-stage purification of the sub-system to separate and purify copper, cadmium and cobalt slag.

[0012] The new high-efficiency pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com