A heating carrier, its control method, and thin film packaging equipment

A control method and a carrier technology, which are applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of reduced lifespan of organic materials, insufficient edge density of packaging films, and reduced reliability and yield of OLED devices. Achieve the effect of increasing the density, improving the insufficient density of the edge of the packaging film, reducing the life of the organic material, and reducing the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

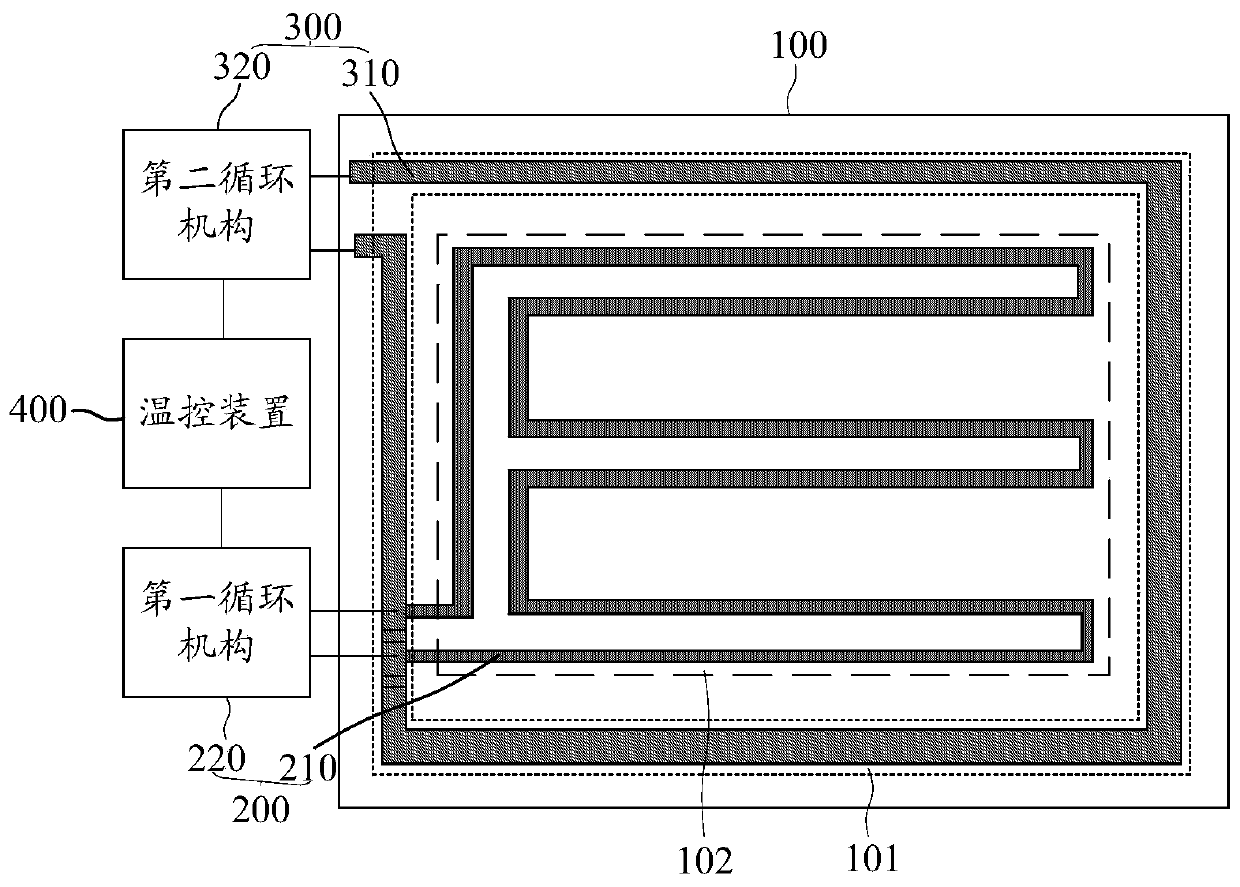

[0031] see figure 1 As shown, the present embodiment provides a heating carrier, comprising:

[0032] The carrying platform body 100, in specific implementation, the carrying platform body 100 is provided with a carrying surface for carrying the substrate;

[0033] The first heating device 200, the first heating device 200 forms a first heating area 101 on the carrier body 100, in specific implementation, the first heating area 101 is set on the carrier surface;

[0034] The second heating device 300, the second heating device 300 forms a second heating area 102 on the carrier body 100, the second heating area 102 is arranged around the first heating area 101, in specific implementation, the second heating area 102 is arranged on the carrier surface superior;

[0035] A temperature control device 400, the temperature control device 400 is respectively connected to the first heating device 200 and the second heating device 300, and is used to control the temperature of the fi...

Embodiment 2

[0044] This embodiment provides a method for controlling the heating carrier as provided in Embodiment 1 above, and the control method specifically includes:

[0045] The temperature control device 400 controls the temperature of the second heating device 300 to be higher than the temperature of the first heating device 200 during the heating process, and controls the temperature of the first heating device 200 to gradually decrease during the heating process.

[0046] During the use of current OLED devices, water and oxygen usually infiltrate from the edge of the encapsulation film, resulting in a decrease in the service life of the OLED device. Therefore, increasing the density of the edge of the encapsulation film can reduce the probability of water and oxygen infiltration. During the deposition process of the packaging film, the temperature of the substrate has an important influence on the properties and structural stability of the packaging film. Increasing the temperatur...

Embodiment 3

[0053] Based on the same inventive concept, the present invention also provides a thin film encapsulation device, including the heating platform provided in the first embodiment above. In a specific implementation, the thin film packaging equipment further includes a plasma gas generating device.

[0054] The thin film encapsulation equipment provided in this embodiment also solves the problems in the prior art that the edge density of the encapsulation film of the OLED device is insufficient and the lifespan of the organic material is shortened by the heated stage, which further leads to a decrease in the reliability and yield of the OLED device. For its principle and specific implementation, refer to Embodiment 1 above, and details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com