Active clamping forward switching power supply circuit

A switching power supply circuit and clamping technology, applied to electrical components, adjusting electrical variables, instruments, etc., can solve the problems that the duty cycle cannot be greater than 0.5, cannot be realized, and the power density is low, so as to improve the conversion efficiency and realize energy recovery , the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

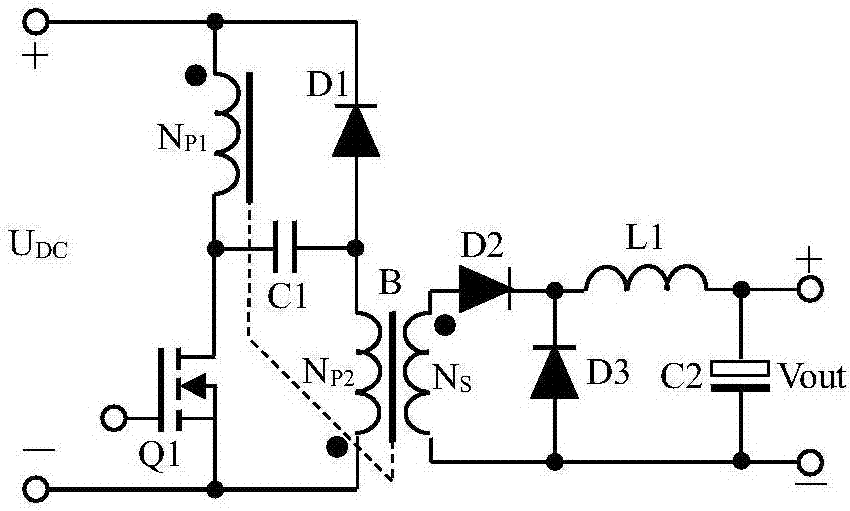

[0042] Figure 2-1 , Figure 2-2 It shows the principle diagram of the active clamp forward switching power supply of the first embodiment of the present invention, including a transformer B, a first N-channel field effect transistor Q1, a first capacitor C1, a second capacitor C2, and a clamping network 400. The first diode D3, the second diode D2, the first inductor L1, the transformer B includes the first primary winding N P1 , the second primary winding N P2 and the secondary winding N S , the clamping network 400 includes at least an anode and a cathode, and the secondary winding N S The terminal with the same name is connected to the anode of the second diode D2, and the cathode of the second diode D2 is connected to the cathode of the first diode D3 and one end of the first inductor L1 at the same time, and the other end of the first inductor L1 is connected to the second capacitor C2 One end is connected and forms the output positive, which is the + end of Vout in ...

no. 2 example

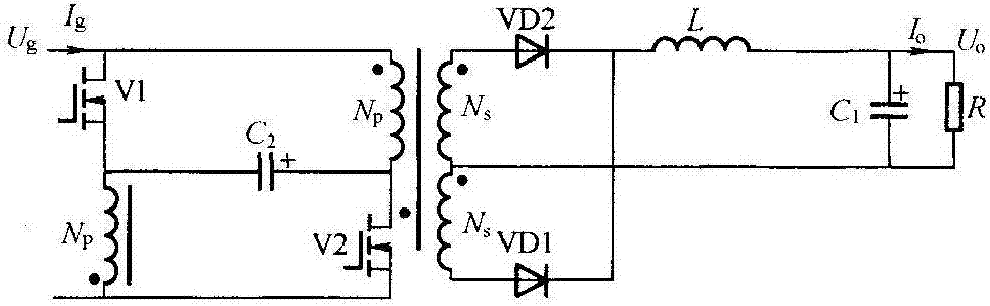

[0075] The present invention also provides an equivalent solution to the above-mentioned first embodiment, corresponding to solution 2, see Figure 3-1 , Figure 3-2 , an active clamp forward switching power supply, comprising a transformer B, a first N-channel FET Q1, a first capacitor C1, a second capacitor C2, a clamping network 400, a second diode D2, a first capacitor C2 A diode D3, a first inductor L1, and a transformer B including a first primary winding N P1 , the second primary winding N P2 and the secondary winding N S , the clamping network 400 includes at least an anode and a cathode, and the secondary winding N S The terminal with the same name is connected to the anode of the second diode D2, and the cathode of the second diode D2 is connected to the cathode of the first diode D3 and one end of the first inductor L1 at the same time, and the other end of the first inductor L1 is connected to the second capacitor C2 One end is connected and forms the output po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com